Pressing machine with servo motors and control method thereof

A technology of servo motor and control method, which is applied in the field of presses, can solve the problems of unification and difficult application of parallel mechanisms, and achieve the effects of reducing working noise, reducing the volume of the whole machine and manufacturing cost, and high synchronization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

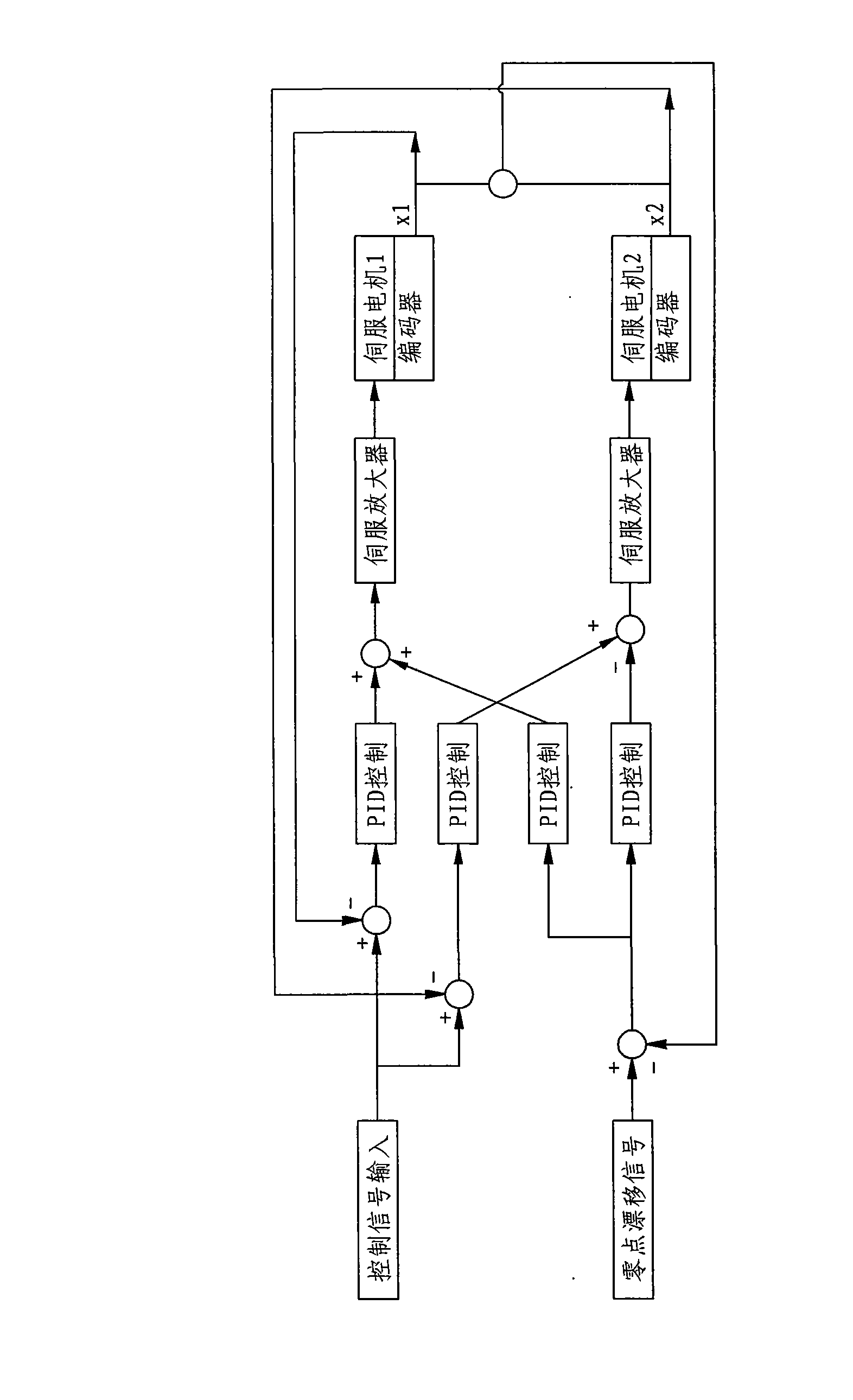

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

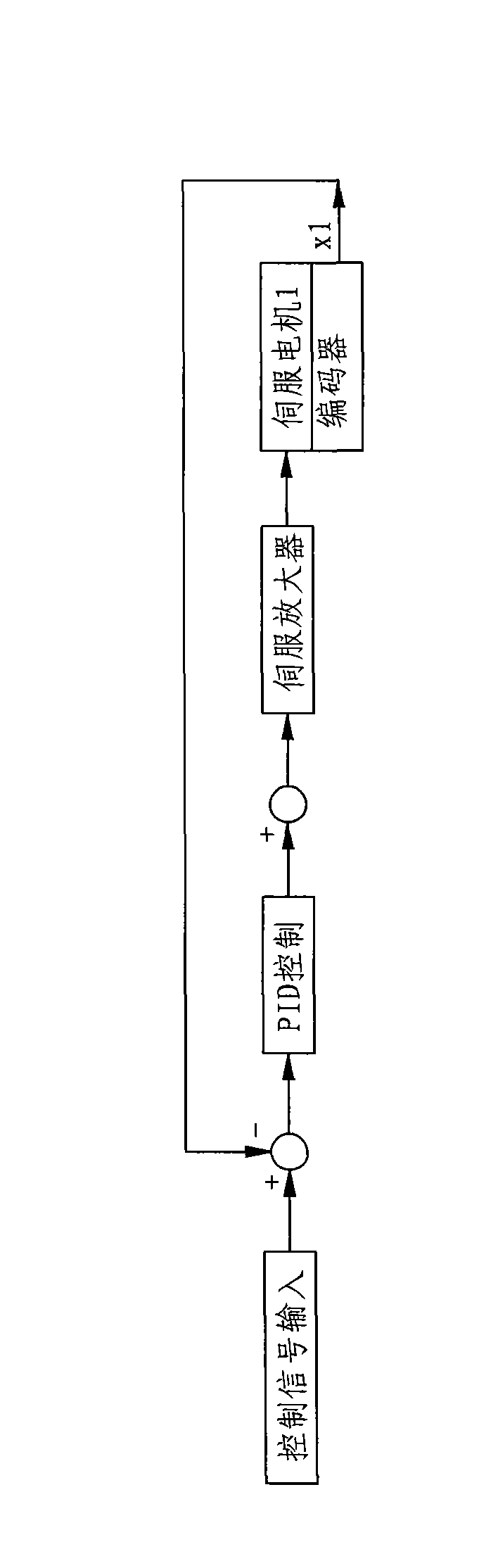

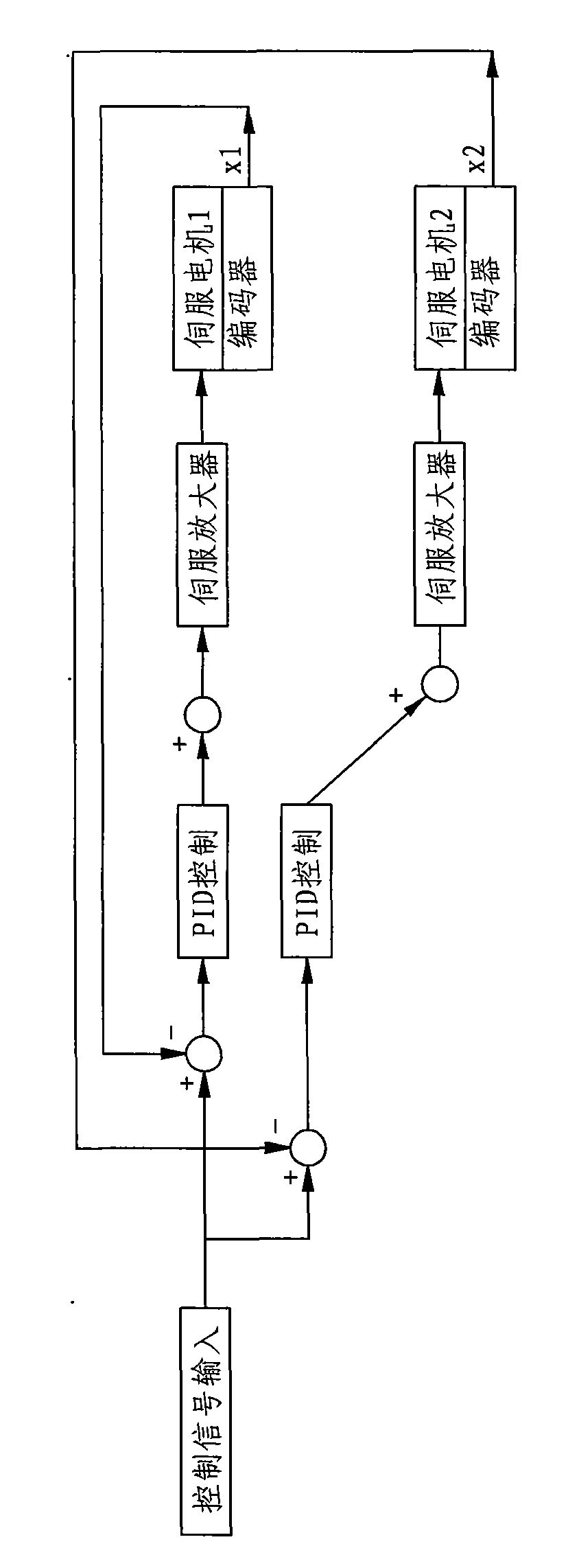

[0013] see image 3 , the press machine with servo motors, including the press machine and two servo motors 1 and 2 with encoders, each servo motor is connected to a branch transmission mechanism, and all branch transmission mechanisms are connected in parallel to the slider; Wherein, each servo motor adopts closed-loop control, and a synchronous ring is arranged between the servo motors to ensure the synchronization of all servo motors. The servo motor rotates 360°, the maximum speed of the servo motor is 1000RPM, and the control accuracy of the synchronous ring is ±0.05°.

[0014] During control, on the basis of the traditional closed-loop control of each servo motor, first compare the feedback signals of the encoders of each servo motor to obtain the difference value Δx, Δx=x1-x2, and then compensate to each In the PID controller of the servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com