Millet jelly and production method thereof

A technology of millet jelly and millet, applied in the application, food preparation, food science and other directions, can solve the problems of affecting the stability of beverages, unseen products, and precipitation of millet beverages. The effect of increasing the variety of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Produce the millet jelly (in one ton of product) of the present embodiment according to following formula:

[0048] Millet Granules 100kg

[0049] Millet flour 5kg

[0050] Gelatin 3.0 kg

[0051] Carrageenan 0.3 kg

[0052] White sugar 50kg

[0053] Multivitamin A / D 0.2kg

[0054] Food flavor 1.0 kg

[0055] water balance.

[0056] Raw material standards: The millet grains are uniform in color, smooth and smooth, with normal smell, free of impurities, and the content of broken rice does not exceed 6%; the selection of each raw material meets the requirements of relevant quality standards.

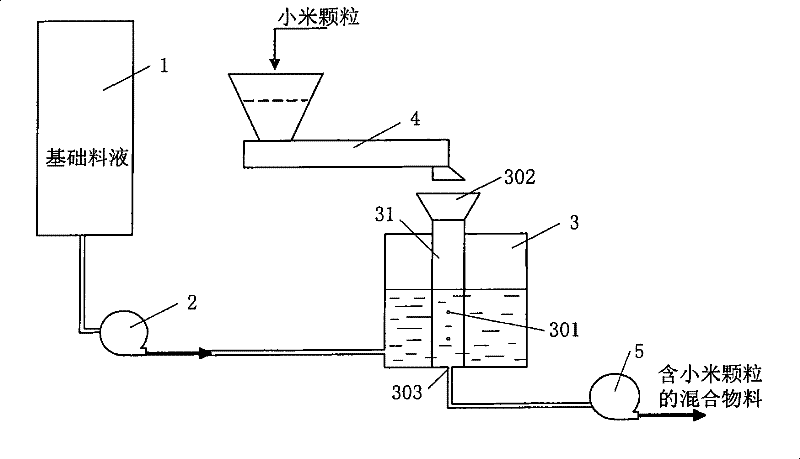

[0057] The production method of the millet jelly containing millet grain of the present embodiment can refer to figure 1 As shown, the main steps are:

[0058] 1. Preparation of basic material liquid:

[0059] Dissolving and mixing materials: fully dissolve white sugar and stabilizers (gelatin, carrageenan) in the batching water (usually the temperature of the stabilizer is...

Embodiment 2

[0065] The millet jelly of this embodiment is produced according to the following formula (in terms of one ton of product, the quality of each raw material meets relevant national or industry standards):

[0066] Millet Granules 80kg

[0067] Millet flour 3kg

[0068] Gellan Gum 1.5kg

[0069] Microcrystalline cellulose 2.0 kg

[0070] Food flavor 0.8 kg

[0071] Milk 800kg

[0072] water balance.

[0073] The production method of the millet jelly containing millet granules in this embodiment is basically the same as that in Example 1, wherein the batching milk is used to replace part of the batching water to make the ingredients, and the millet jelly containing millet granules in this embodiment is produced.

[0074] The product characteristics of the millet jelly of the present embodiment are: the millet content is about 8% (dry weight), contains about 2.9% milk fat and about 2.5% milk protein simultaneously, is nutritious, and the product pH value is about 6.6. The ov...

Embodiment 3

[0076] The millet jelly of this embodiment is produced according to the following formula (in terms of one ton of product, the quality of each raw material meets relevant national or industry standards):

[0077] Millet Granules 140kg

[0078] corn flour 5kg

[0079] Gelatin 1.0 kg

[0080] Carrageenan 0.15 kg

[0081] Monoglycerides 1 kg

[0082] 40kg white sugar

[0083] Dietary fiber 1 kg

[0084] Food flavor 1.0 kg

[0085] Milk 350kg

[0086] water balance.

[0087] In the production method of millet jelly containing millet granules in this embodiment, the dietary fiber is added together with a stabilizer to prepare a base liquid, and other processes are basically the same as in Example 2 to obtain the millet jelly containing millet granules in this embodiment.

[0088] The product characteristics of the millet jelly containing millet granules in this embodiment are: millet content about 14% (dry weight), sucrose content about 4.0%, containing about 1.1% milk fat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com