Device for constituting permanent magnet full-acting surface

An active surface, permanent magnet technology, applied in the direction of permanent magnet, magnetic separation, inductor/transformer/magnet manufacturing, etc., can solve the problems of high manufacturing cost, complex manufacturing, low yield, etc., and achieve high sorting capacity and easy installation. , the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

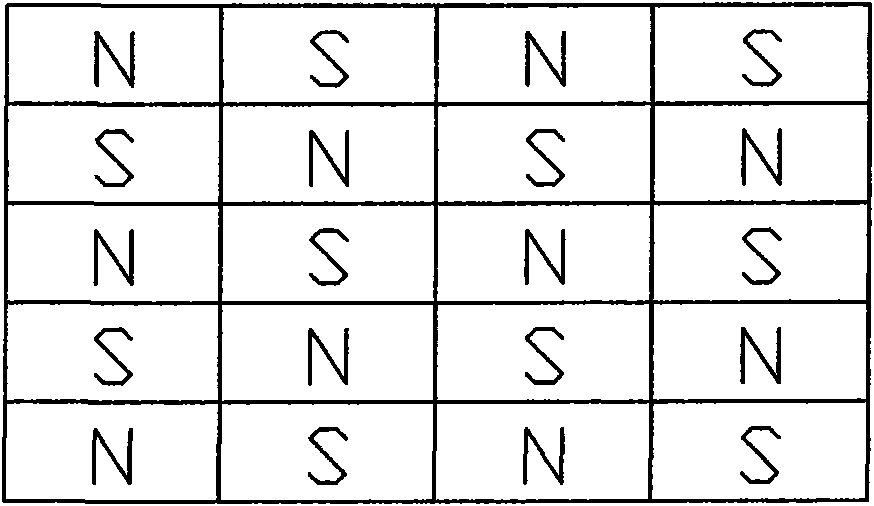

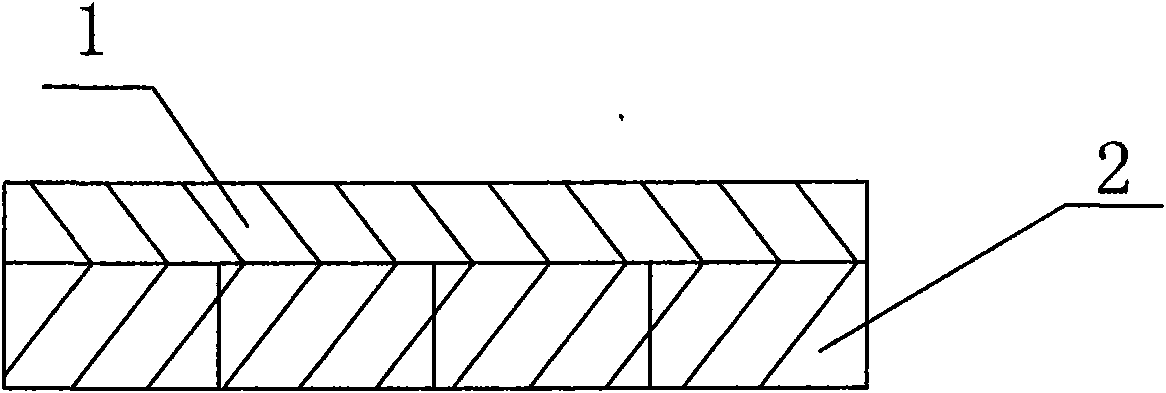

[0041] Embodiment 1. is used for the magnetic separator of sorting limonite, hematite:

[0042] Such as Figures 4 to 6 Shown: on the top of the cylinder with a diameter of 1200mm and a length of 2000mm, tiny permanent magnets 2 are covered along its radial and axial directions to form a permanent magnet action surface 3, and the polarities of two adjacent tiny permanent magnets are opposite. The tiny permanent magnet grade is N42, the length is 15mm, the width is 4mm, and the height is 3mm (15×4×3mm), where the height is the excitation direction of the permanent magnet. The surface magnetic field intensity of the permanent magnet action surface 3 is 4500-5000GS. The cylinder body is a magnetizer 1, which is made of a common steel plate with a thickness of 8mm; the cylinder body is connected to the transmission equipment of the magnetic separator through a shaft. Thus, a magnetic separator having a magnetic roll of 1200 mm in diameter and 2000 mm in length was produced.

[...

Embodiment 2

[0045] Embodiment 2. The magnetic separator for separating iron in red mud:

[0046] Adopting the method for embodiment 1 to prepare magnetic rollers is a magnetic separator with a diameter of 1500mm and a length of 4000mm, and the tiny permanent magnet brand N48 is 15mm long, 4mm wide, and 5mm high (15×4×5mm), wherein the high is a permanent magnet direction of excitation. The surface magnetic field intensity of the permanent magnet action surface 3 is 5000-5500GS. Auxiliary with impurity removal device and ore unloading device, this magnetic separator can be used for separation of iron in red mud. The daily processing of raw ore can reach 1,000 tons.

[0047] For example, when the red mud in Pingguo area of Guangxi is sorted, when the raw ore grade is 26.02%, the magnetic separator can obtain a concentrate grade of 58.23%, a tailing grade of 21.05%, and a recovery rate of 41.70%.

Embodiment 3

[0048] Embodiment 3. is used for the magnetic separator of sorting chromite:

[0049] Adopting the method for embodiment 1 to prepare magnetic rollers is a magnetic separator with a diameter of 1200mm and a length of 2000mm, and the tiny permanent magnet brand N42 is 15mm long, 4mm wide, and 4mm high (15×4×4mm), wherein the high is a permanent magnet direction of excitation. The surface magnetic field intensity of the permanent magnet action surface 3 is 3000-3500GS. Auxiliary with impurity removal device and ore unloading device, this magnetic separator can be used for the separation of chromite ore. The daily processing of raw ore can reach 500 tons.

[0050] For example, when sorting chromite with a particle size of -0.15mm, when the chromium in the raw ore is 28.17%, the magnetic separator can obtain a concentrate with a chromium grade of 49.27% and an iron grade of 16.70%. The grade of chromium is 10.70%, and the recovery rate of chromium is 78.00%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com