Gas direct contact type ice slurry preparation system

A contact type, ice slurry technology, applied in air conditioning systems, ice making, ice making, etc., can solve the problems of destroying the heat transfer performance of the ice slurry generator, affecting the overall performance of the system, and destroying the performance of the refrigeration system, etc., to achieve internal temperature distribution Uniform, continuous heat transfer efficiency, cheap and easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

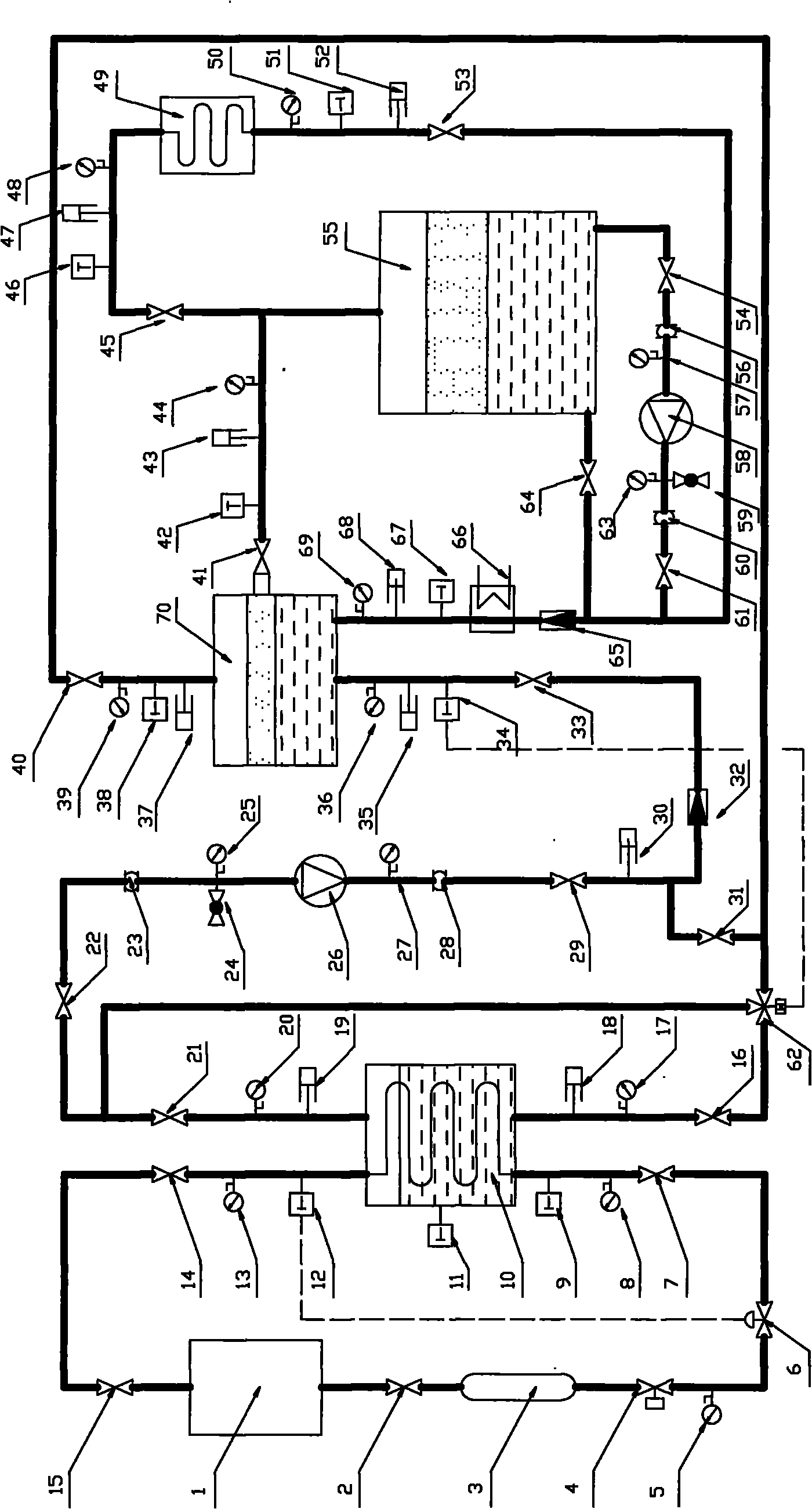

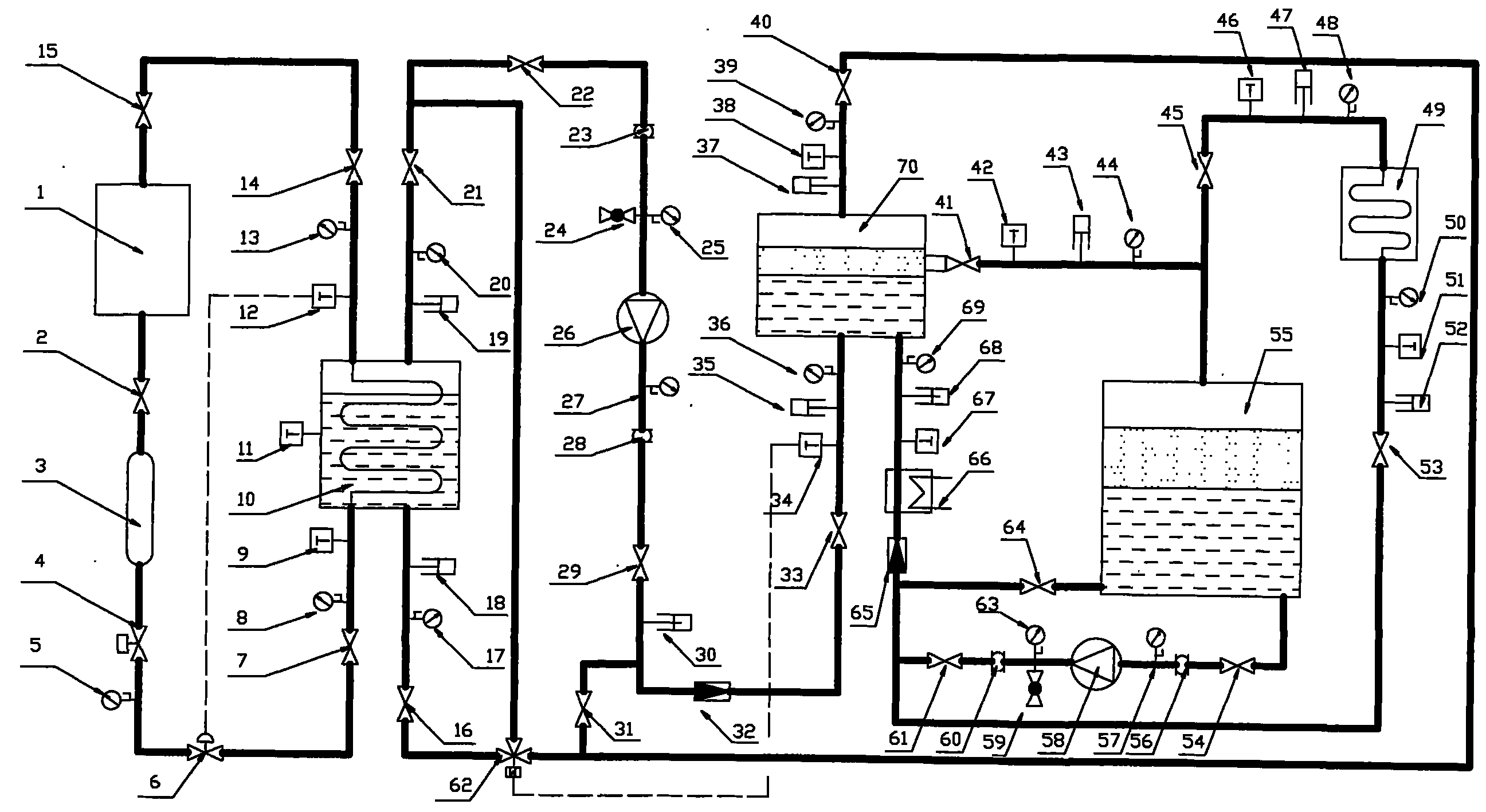

[0012] As shown in the figure, the gas direct contact ice slurry production system is composed of three parts: refrigerant cycle, gas cycle and ice making solution cycle: the refrigerant cycle includes a refrigeration unit 1, a dry filter 3, and a solenoid valve connected in sequence 4. Thermal expansion valve 6, primary heat exchanger 10, wherein the outlet of refrigeration unit 1 and the inlet 3 of the dry filter are connected through the first cut-off valve 2, and a first pressure gauge 5 is arranged between the solenoid valve 4 and the thermal expansion valve 6, The thermal expansion valve 6 is connected to the refrigerant inlet of the primary heat exchanger 10 through the second stop valve 7, the refrigerant inlet of the primary heat exchanger 10 is provided with a second pressure gauge 8 and a first temperature sensor 9, and the primary heat exchanger 10 is provided with a second temperature sensor 11, the refrigerant outlet of the primary heat exchanger 10 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com