Extrusion-type textile flexibility dewatering method and device

A dewatering device, extrusion technology, applied in washing devices, textiles and papermaking, mechanical pressure/force control, etc., can solve problems such as damage to textiles, wrinkles, and lower moisture content of textiles, and achieve the effect of less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

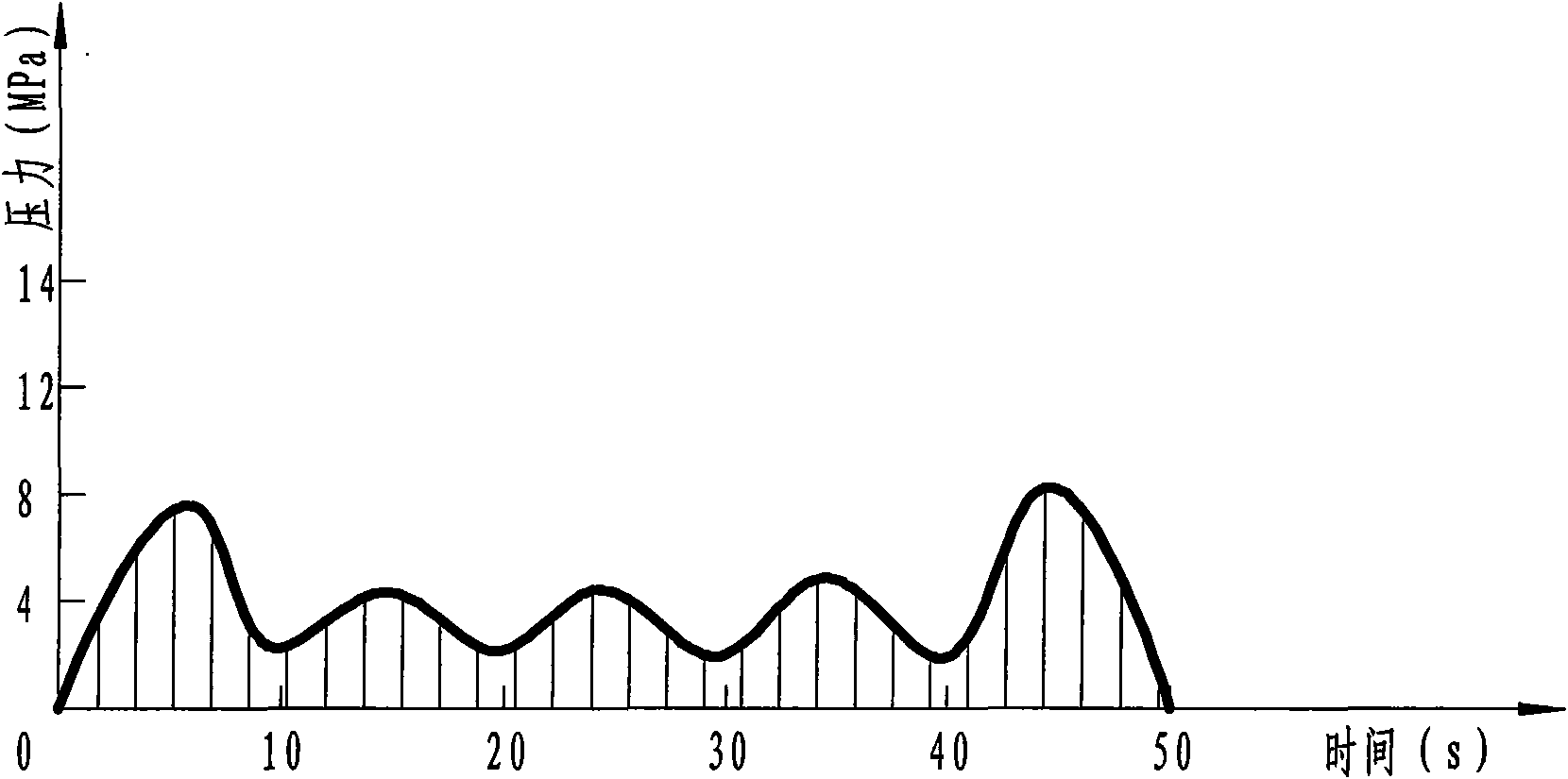

[0023] Example 1: The dehydration experiment of cotton, according to the characteristics of cotton: ① good hygroscopicity; ② wet strength is greater than dry strength, but overall firm and durable; ③ poor wrinkle resistance, large shrinkage. Therefore, the applicant chooses as figure 2 Shown pressure curve adopts device and method of the present invention, compares with traditional centrifugal dehydration, obtains following data:

[0024]

Embodiment 2

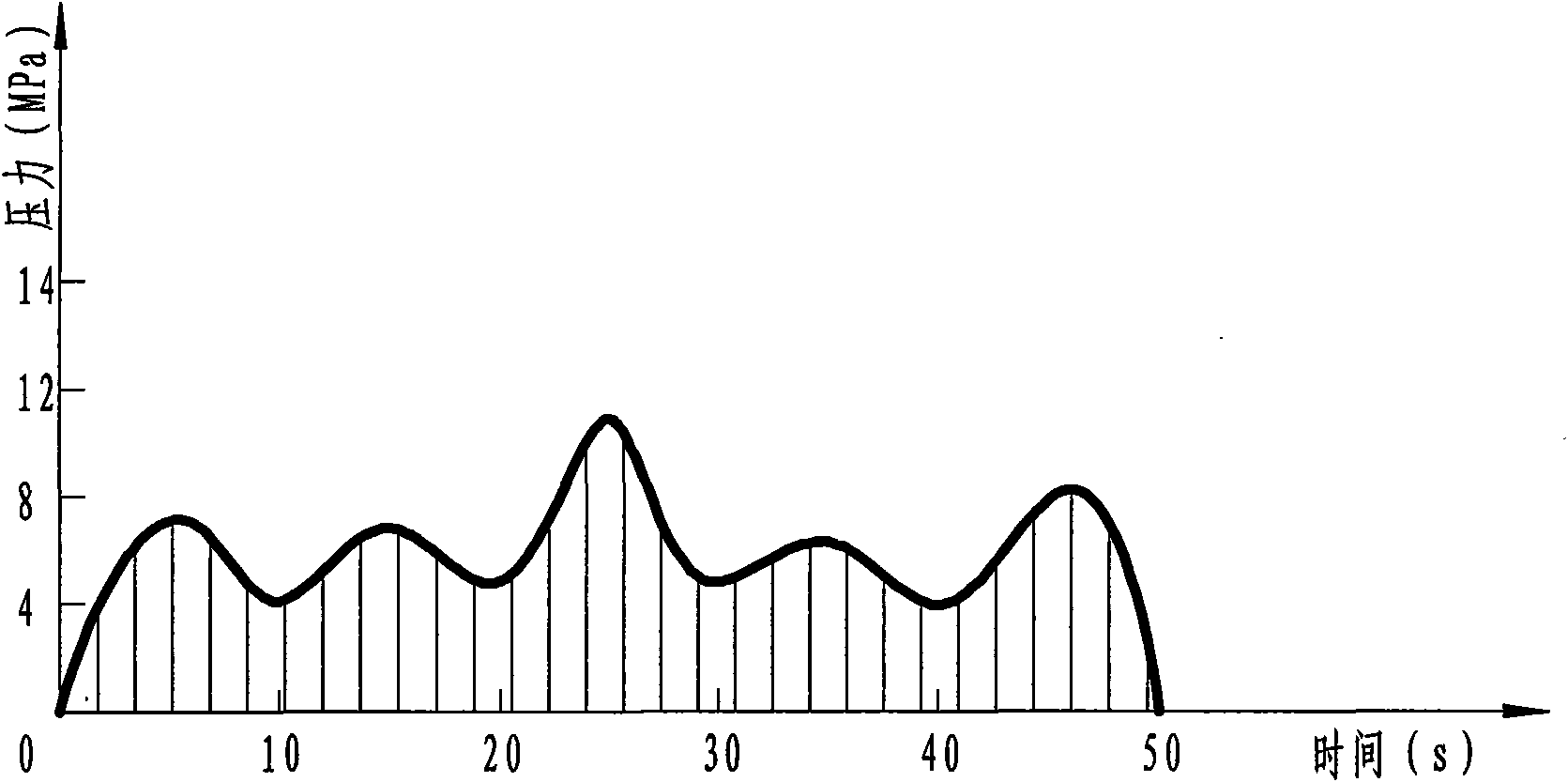

[0025] Embodiment 2: For the dehydration experiment of hemp, according to the characteristics of hemp: 1. good air permeability; 2. easy to wrinkle and poor drape; Therefore, the applicant chooses as image 3 Shown pressure curve adopts device and method of the present invention, compares with traditional centrifugal dehydration, obtains following data:

[0026]

Embodiment 3

[0027] Embodiment three: for the dehydration experiment of wool, according to the characteristics of wool: 1. protein fiber; 2. soft to the touch, more elastic than other natural fibers such as cotton, hemp, silk, etc., and good wrinkle resistance. Therefore, the applicant chooses as Figure 4 Shown pressure curve adopts device and method of the present invention, compares with traditional centrifugal dehydration, obtains following data:

[0028]

moisture content 1

Moisture content 2

Moisture content 3

Moisture content 4

The device of the present invention

44.5%

44.4%

44.6%

44.4%

centrifugal dehydrator

63.3%

62.2%

63.9%

62.8%

[0029] Based on the data of the above examples, the moisture content of the fabric after dehydration by the dehydration device and method of the present invention is less than 50%, and the dehydration effect is better than that of the centrifugal dehydrator.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com