Low-temperature magnetic cooling erbium-based bulk amorphous material

An amorphous material and magnetic refrigeration technology, which is applied in the field of magnetic refrigeration alloys, can solve the problems of Freon compression refrigeration and other problems, and achieve the effects of favorable energy utilization, simple preparation process, and wide applicable temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

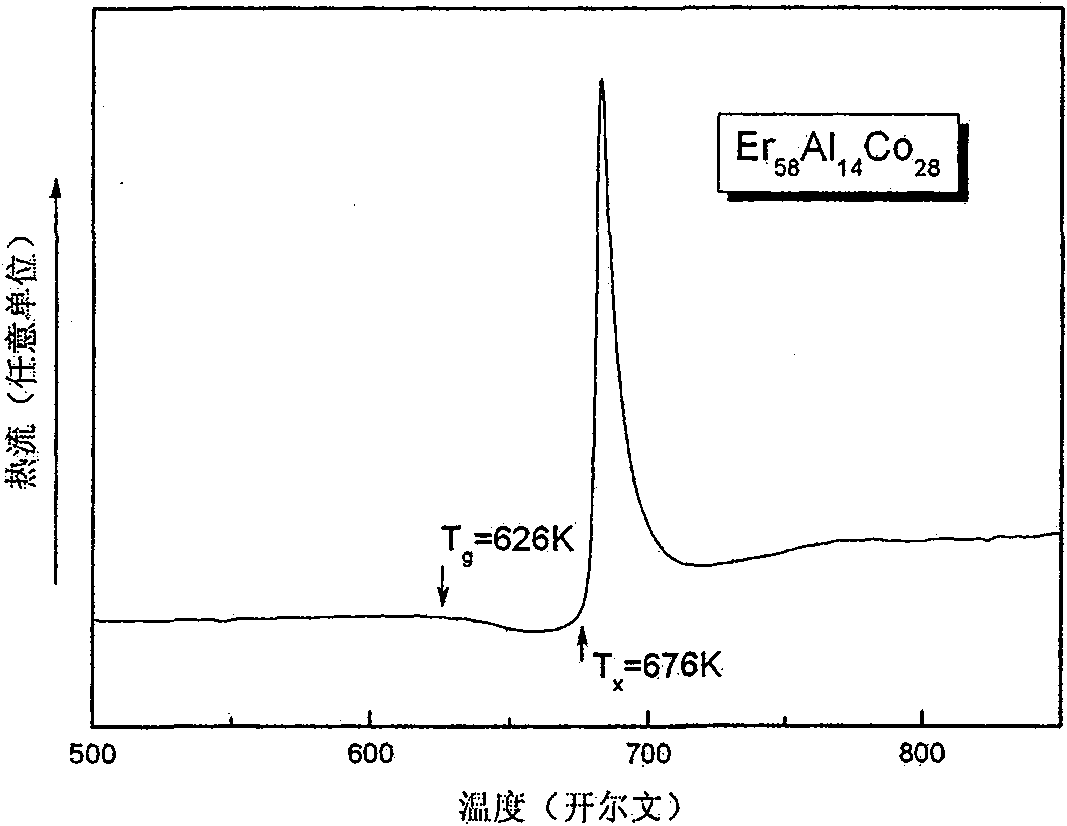

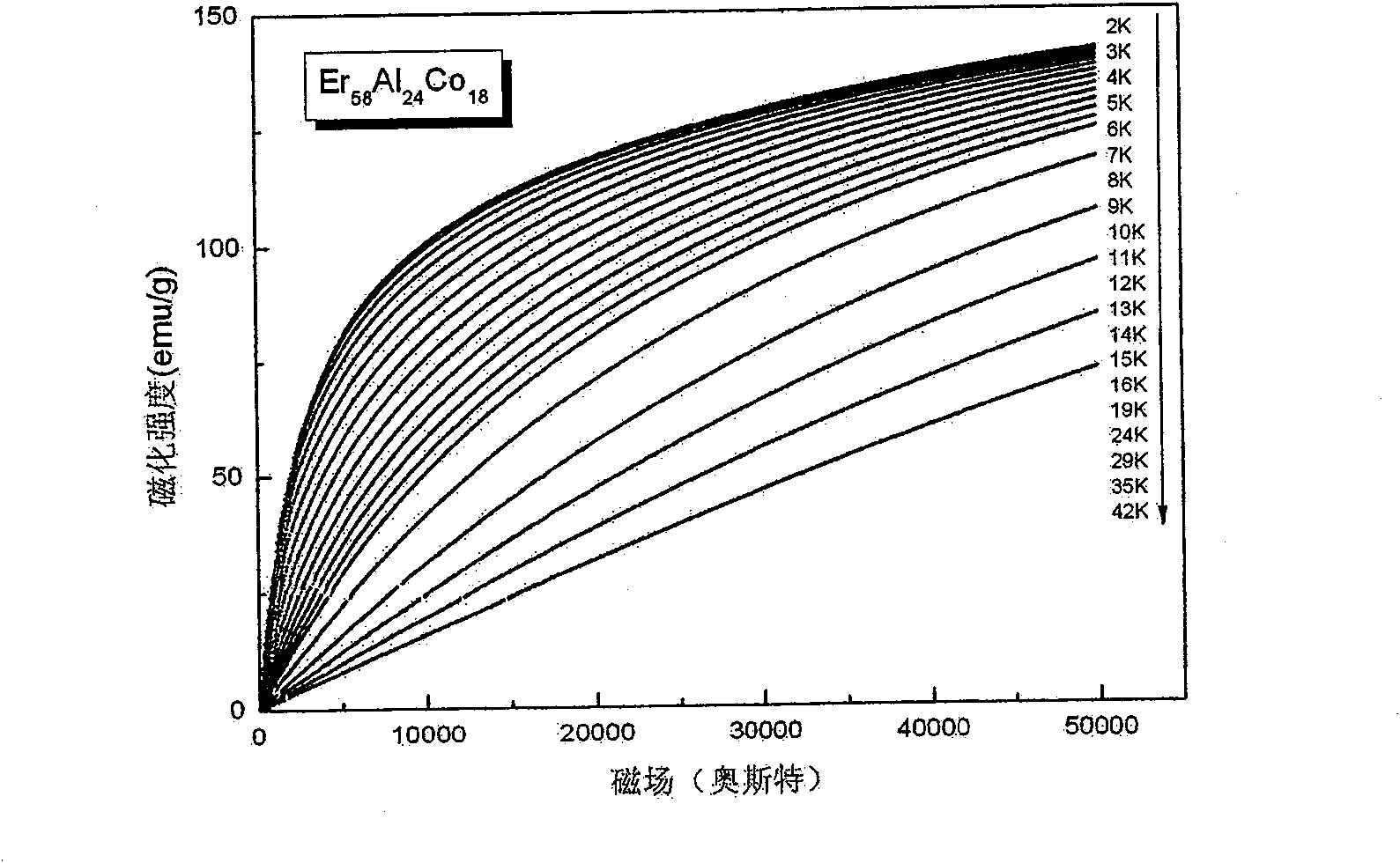

[0020] Using commercially available pure metals Er, Al, Co (purity higher than 99.5%, weight percentage) as starting materials, first arc melting in an argon atmosphere protected by oxygen absorption of titanium ingots, each alloy needs to be melted 5 times, with Ensure that the composition of the master alloy is uniform. The nominal composition (atomic percentage) of embodiment alloy is respectively Er 56 al 24 co 20 、Er 58 al 24 co 18 、Er 58 al 22 co 20 and Er 58 al 14 co 28 . Take an appropriate amount of master alloy material and place it in a copper mold with cooling water, re-melt it in an electric arc furnace under an argon atmosphere, and suck the alloy melt into the cavity of the copper mold. The cavity of the copper mold can be designed as round holes with different diameters (such as Ф2mm, Ф3mm, Ф5mm, etc.) according to the needs. Change the alloy composition to Er 58 al 24 co 18 、Er 58 al 22 co 20 、Er 58 al 14 co 28 The master alloy is cast in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com