Automatic head burning and molding blanking machine of cable lining

A technology of blanking machine and forming mechanism, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of affecting the quality of finished products, unsafe operation, different lengths, etc., to save labor costs, ensure the quality of finished products, work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

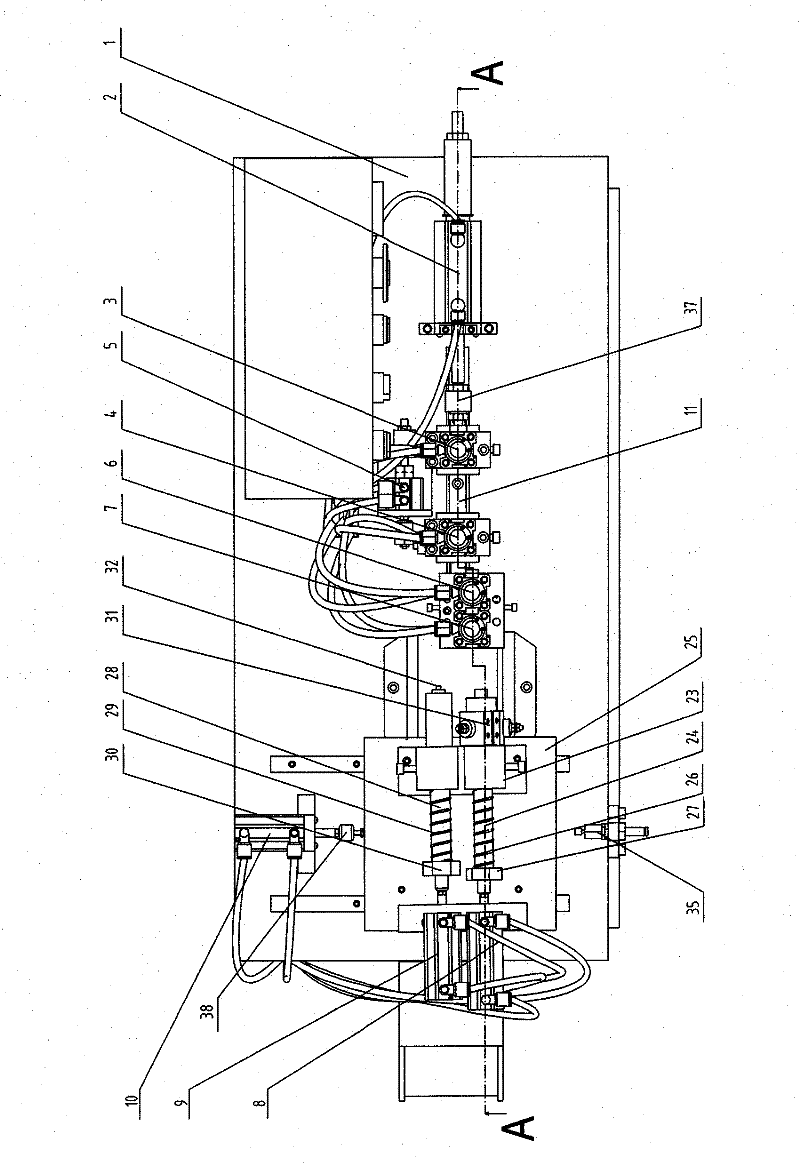

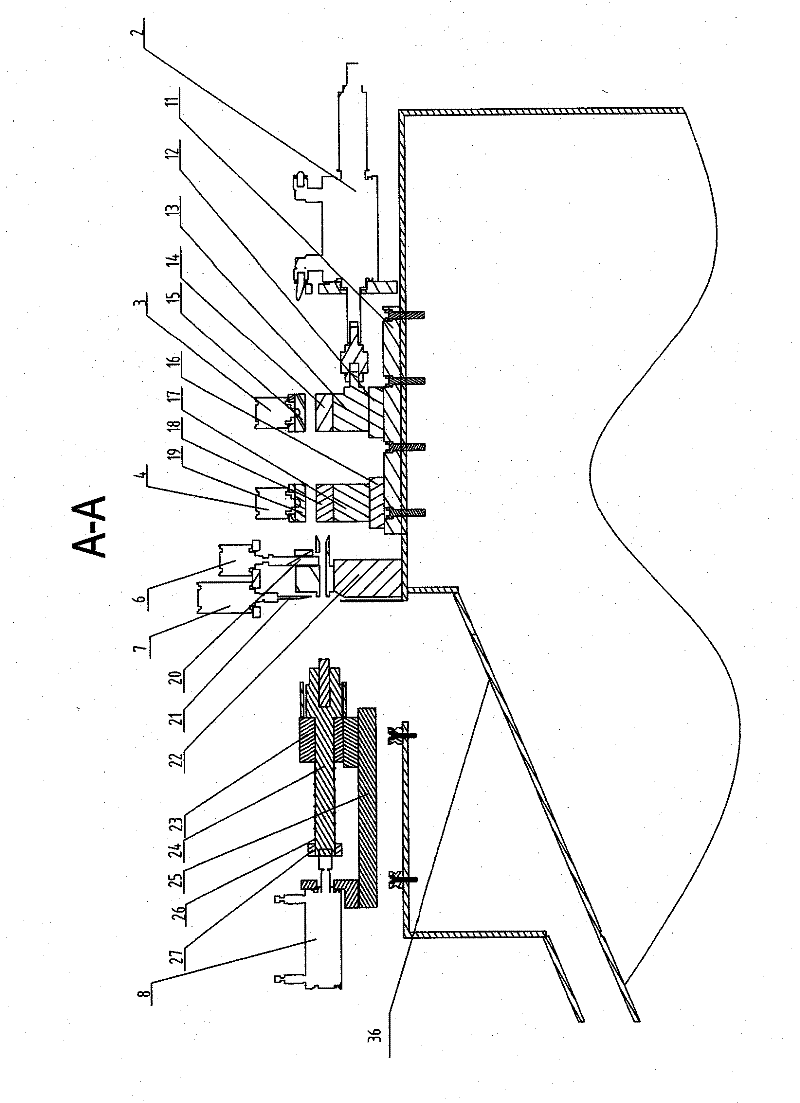

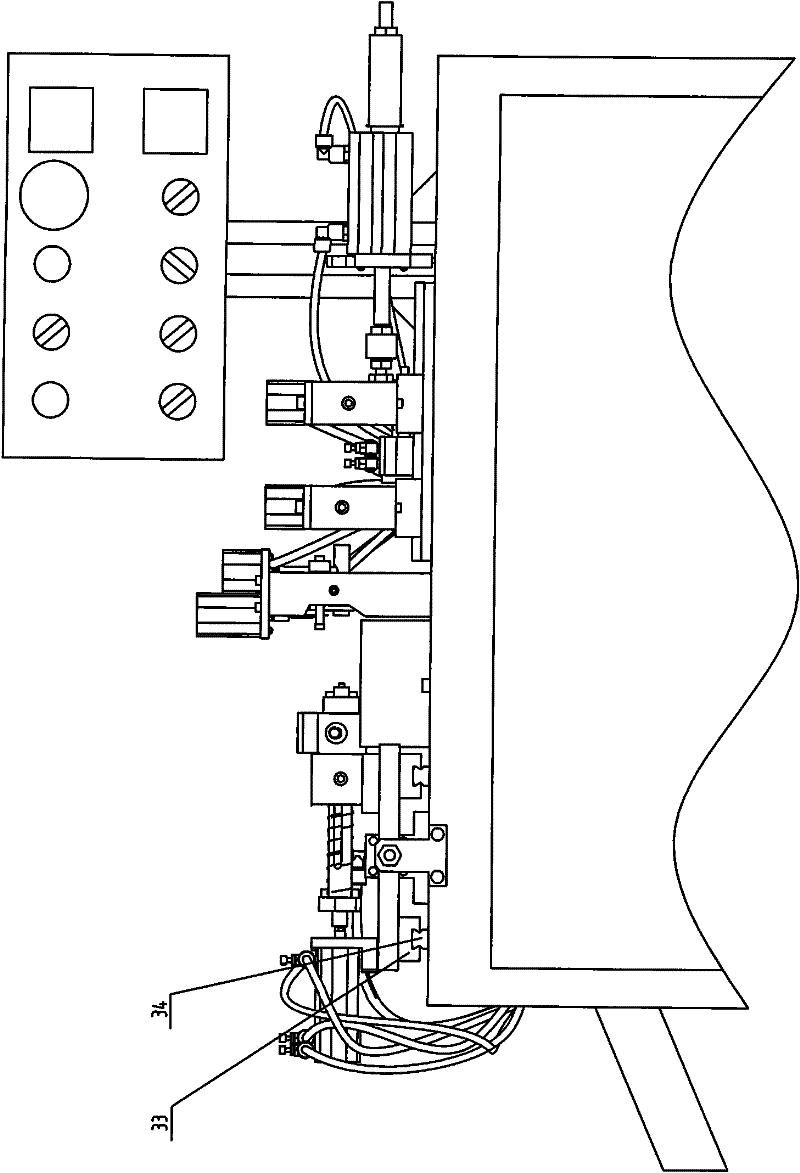

[0023] Such as figure 1 , figure 2 , image 3 As shown, the automatic ironing head forming and blanking machine for the cable lining of the present invention includes a first clamping mechanism and a second clamping mechanism for clamping the lining pipe, which are distributed laterally on the workbench 1 in sequence, and are used for cutting The cutter mechanism of the inner liner, the ironing head forming mechanism for ironing and forming; the horizontal direction refers to from right to left in the drawing, and one side of the first clamping mechanism is fixed to push the first clamping mechanism in the The first cylinder 2 that reciprocates and linearly moves the workbench 1 horizontally, the first cylinder 2 is fixed on the workbench 1 through a bracket, and one side of the second clamp mechanism is fixed to push the second clamp mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com