Method for preventing evaporative pattern casting blind hole crush

A technology of lost foam casting and lost foam, which is applied in the field of smelting and casting, and can solve the problems of unreliable large and deep blind holes, sand sticking, and box collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

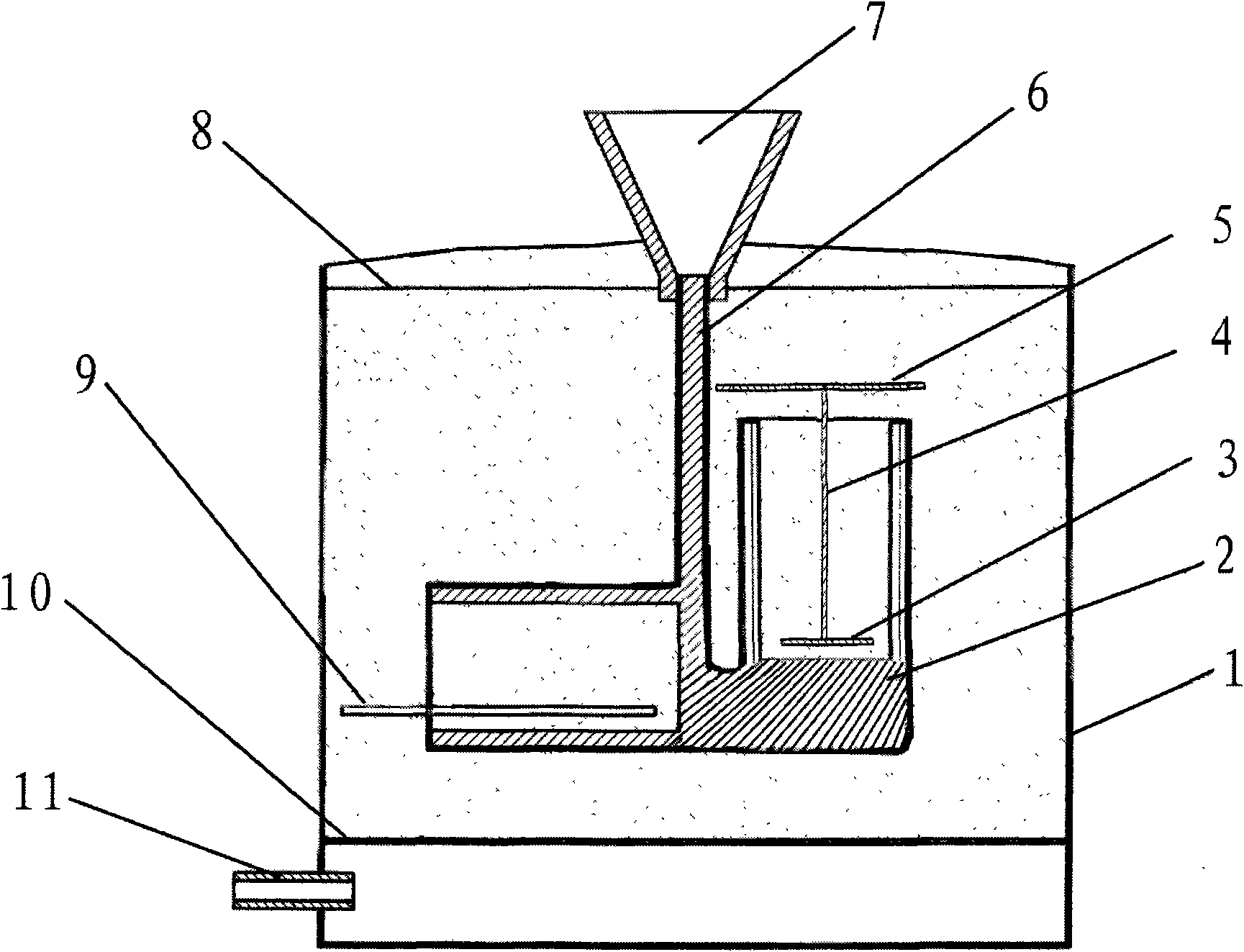

[0022] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0023] See figure 1 The casting process reference diagram is given. Its process steps include:

[0024] 1. First put the sand box 1 on the shaking table, and install a negative pressure pipe 11 at the bottom of the sand box and add a part of dry sand; install a partition 10 with a screen hole on the upper part; Vacuum pump connections for peripherals;

[0025] 2. Then put the lost foam model 2 of the blind hole that has been painted and dried on the dry sand in the sand box 1;

[0026] 3 Add a certain amount of dry sand around the lost foam model 1 of the blind hole;

[0027] 4. Turn on the shaking table to drive the sand box 1 to vibrate, so that the dry sand in the sand box 1 is compacted, and the lost foam model 2 of the blind hole is positioned at the predetermined position;

[0028] 5 Add a small amount of dry sand to the blind hole and scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com