Reactor and method for decalcifying water and simultaneous removal of pollutants

A technology for reactors and pollutants, applied in the field of reactors, can solve the problems of drinking health is not a good thing, unable to achieve plate and reactor heating and aeration, clogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

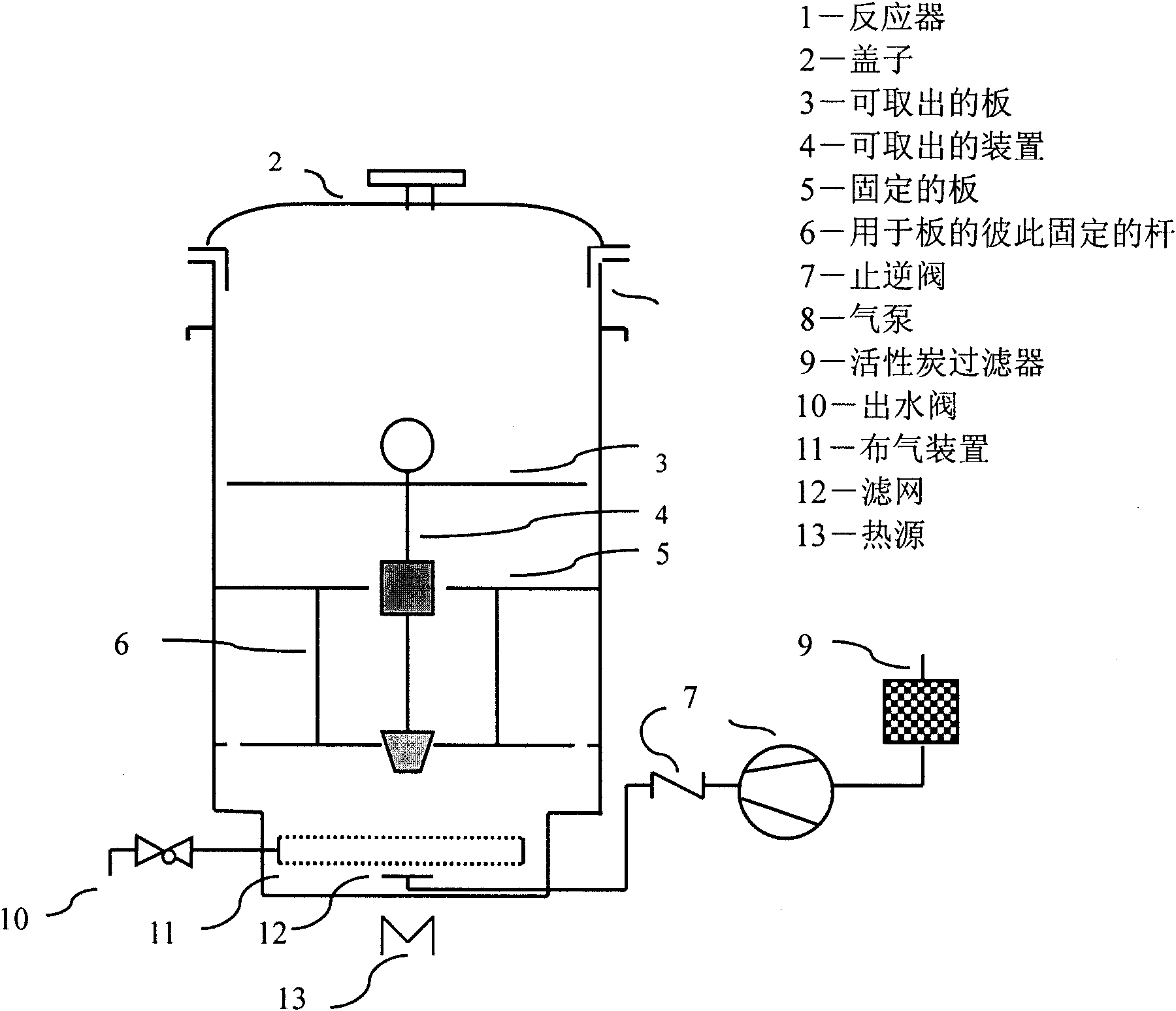

[0040] figure 1 It is the simplest type of reactor and consists of the following components: processing chamber 1, cover 2, non-fixed plate 3, which is connected to a removable device 4, fixed plate 5, for the plates to be fixed to each other Rod 6, check valve 7, air pump 8, activated carbon filter 9, water outlet valve 10, filter screen 11, air distribution device 12, the reactor can be heated from the bottom by an external heat source 13 and water can be manually added.

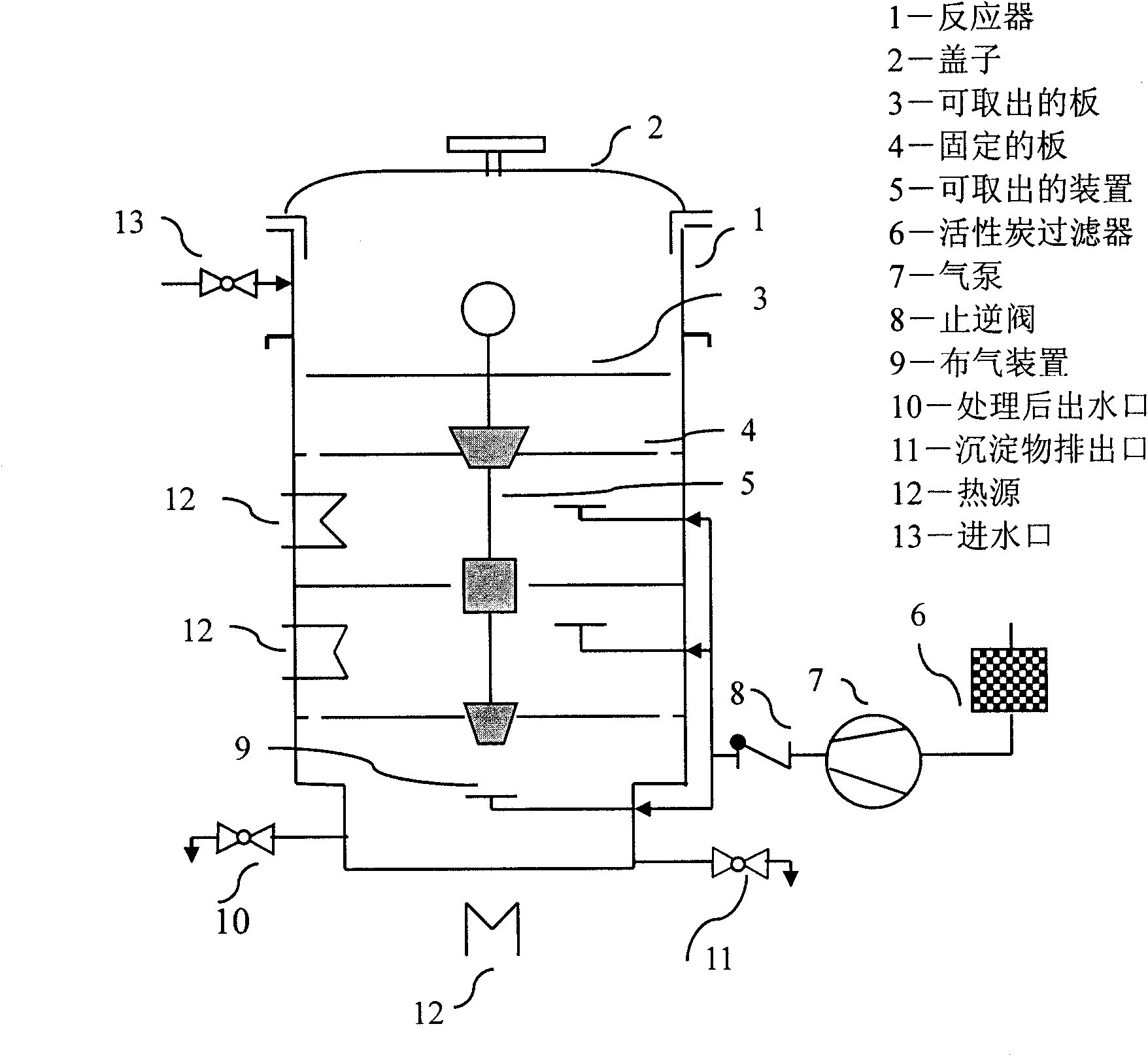

[0041] figure 2 It is a reactor for batch and semi-continuous operation. Water can be injected from above through a second valve at the top, and each section can be additionally heated and aerated.

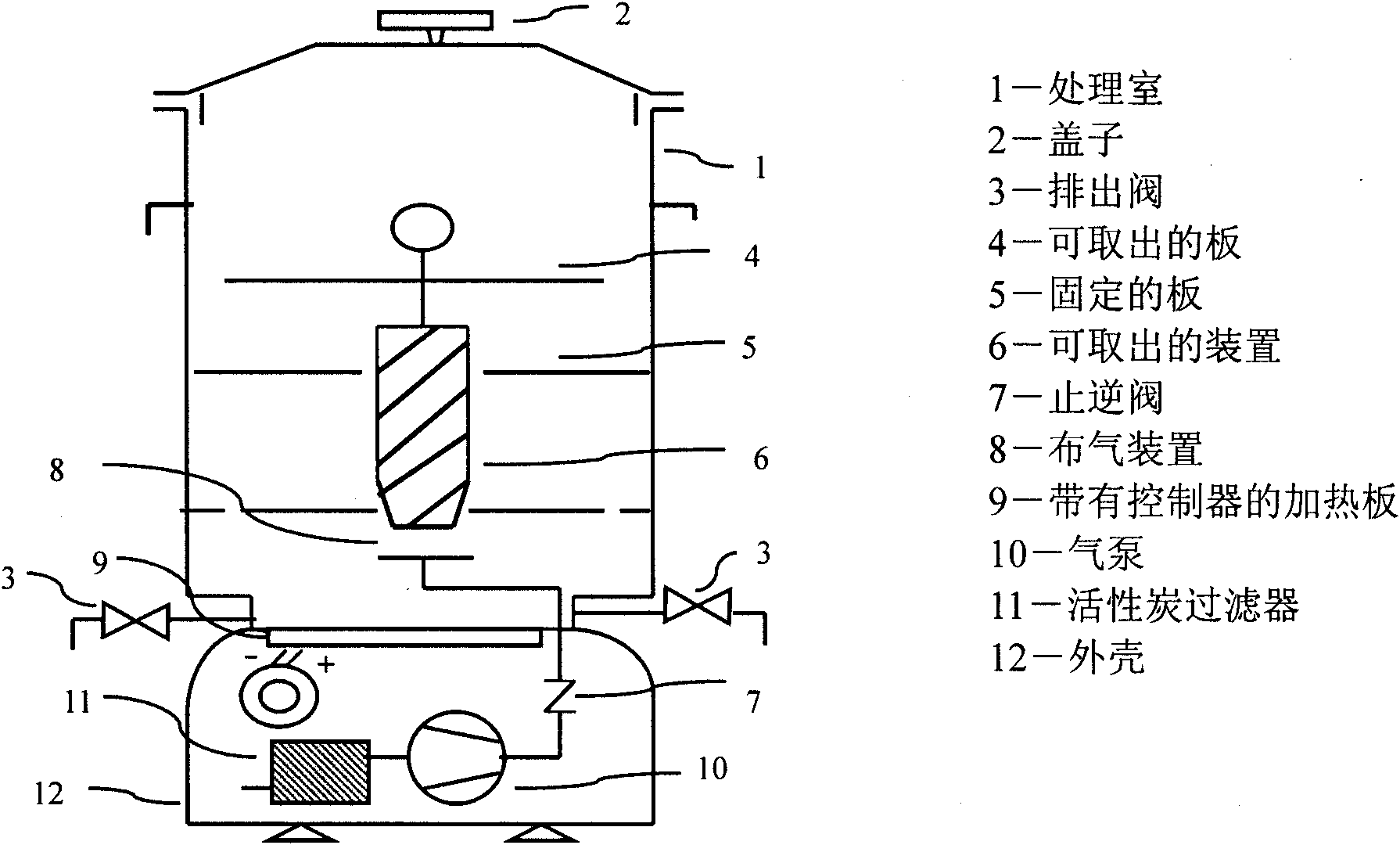

[0042] image 3 , 4 It is another two reactor forms, with electric heating and controller 9, shell and support. The reactor is either fixed on a support to make it easier for water to flow out by raising the height of the treatment chamber and providing a pouring spout at the bottom, or the reactor can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com