Vacuum atomic force microscope and using method thereof

An atomic force microscope and vacuum technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of small scanning range of the microscope and scanning of difficult-to-select areas, and achieve the effect of overcoming design difficulties, large scanning range and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

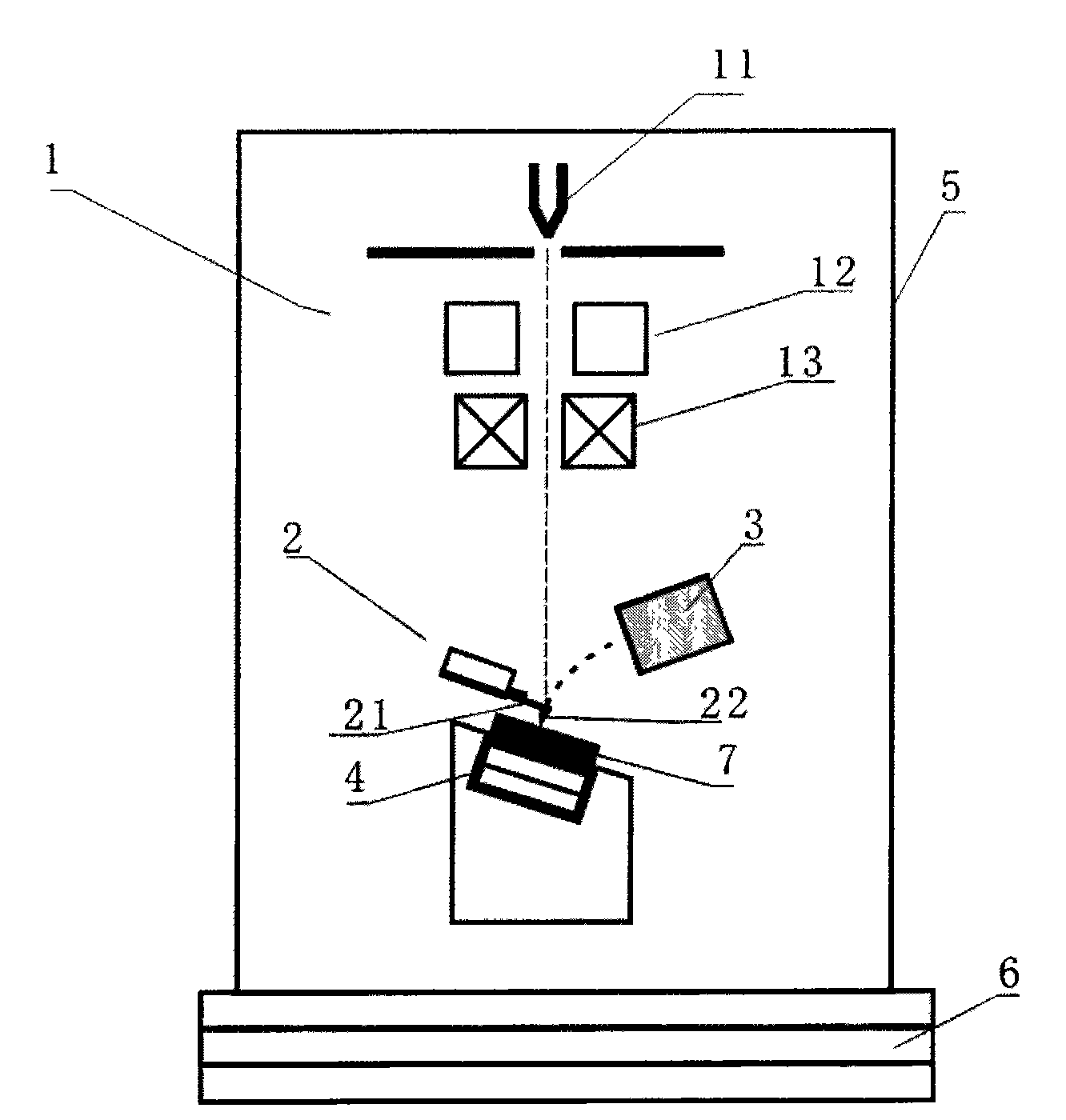

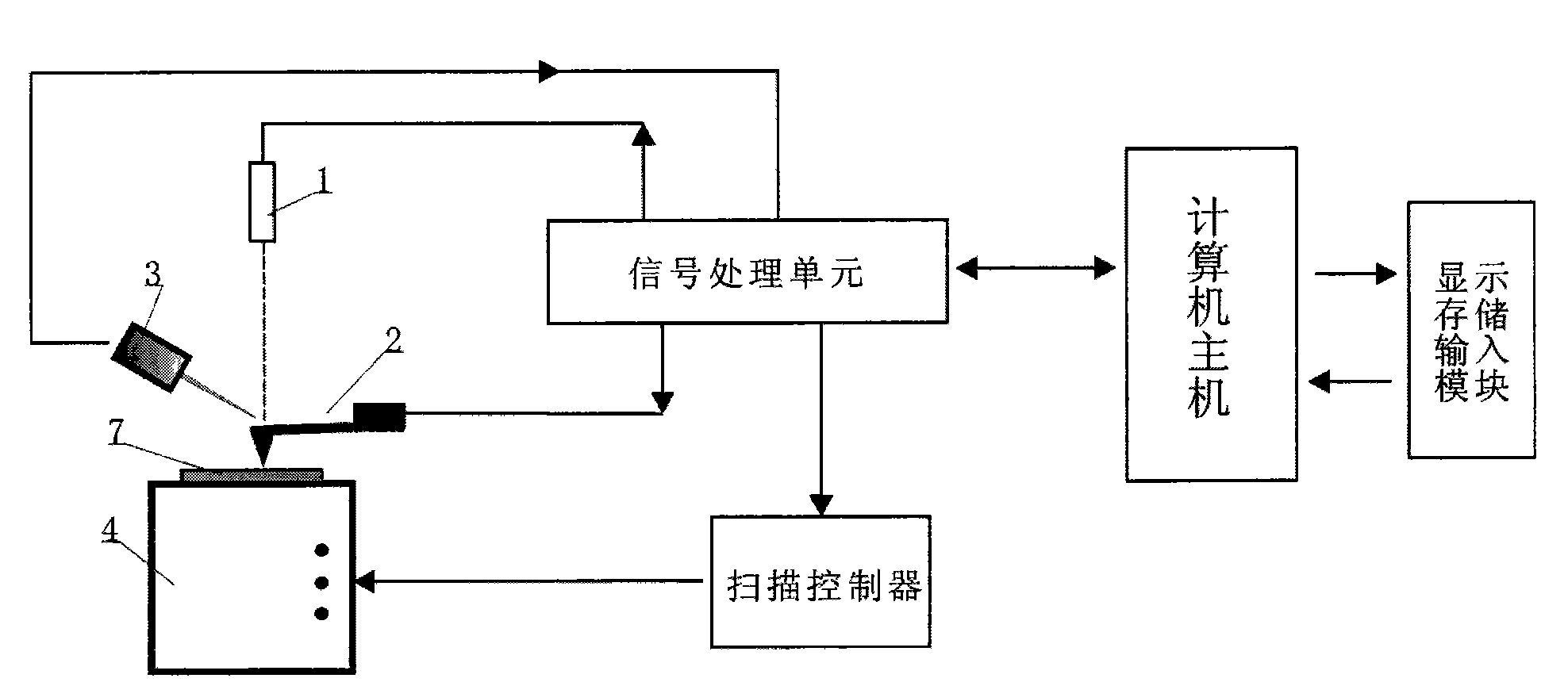

[0019] like figure 1 As shown in the schematic structural diagram of a specific embodiment of the vacuum atomic force microscope system of the present invention, the atomic force microscope mainly includes a feedback controller, a shock absorber 6 at the bottom, a vacuum chamber 5 connected to the shock absorber 6, and a vacuum chamber 5 disposed in the vacuum chamber 5 The electron beam emitting device 1, the probe 2, the secondary electron receiver 3 and the piezoelectric ceramic scanner 4, wherein:

[0020] The electron beam emitting device is composed of an electron gun 11 , an electromagnetic lens 12 and a scanning coil 13 . The electron gun 11 is used to generate electron beams; the electromagnetic lens 12 mainly plays the role of converging, which can focus and reduce the electron beam spot step by step; the scanning coil 13 can be used to control the position of the electron beam irradiation.

[0021] The secondary electron detector 3 is used to detect the secondary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com