Method for forming metal foil by utilizing equipotential line to design variable-profile mold

A technology of metal foil and equipotential lines, which is applied in the field of metal material processing, can solve the problems of difficult surface design in the middle of dynamic profile molds, and achieve the effects of improved forming effect, high processing efficiency, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

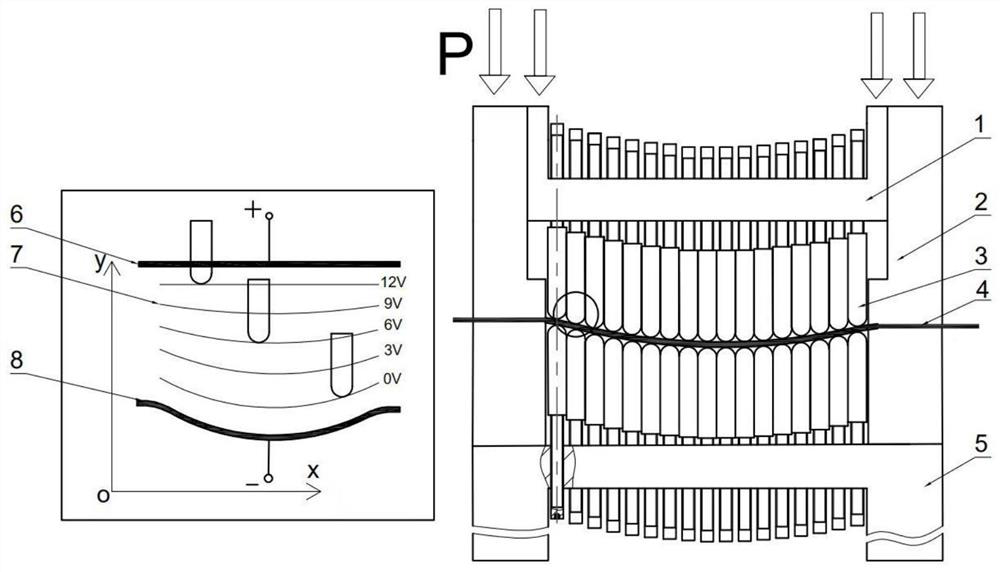

[0015] The present invention also provides a method for using the equipotential line to design a variable profile mold forming metal foil device. Part (8) is used as two electrodes, respectively connected to the positive and negative poles of direct current, and records the distribution of equipotential lines of the electric field generated between the two electrodes. No., No. 3, No. 4, and No. 5, the more the number of equipotential lines according to the voltage value, the more changes in the middle profile and the better the forming effect;

[0016] (2) Establish a coordinate system, calculate the coordinates of each point in each equipotential line, and design the axial movement position of each height-adjustable ball head cylinder in the dynamic profile mold (3) during the forming process, so that the mold The shape of the profile is always consistent with the shape of the equipotential line with different numbers during the forming process;

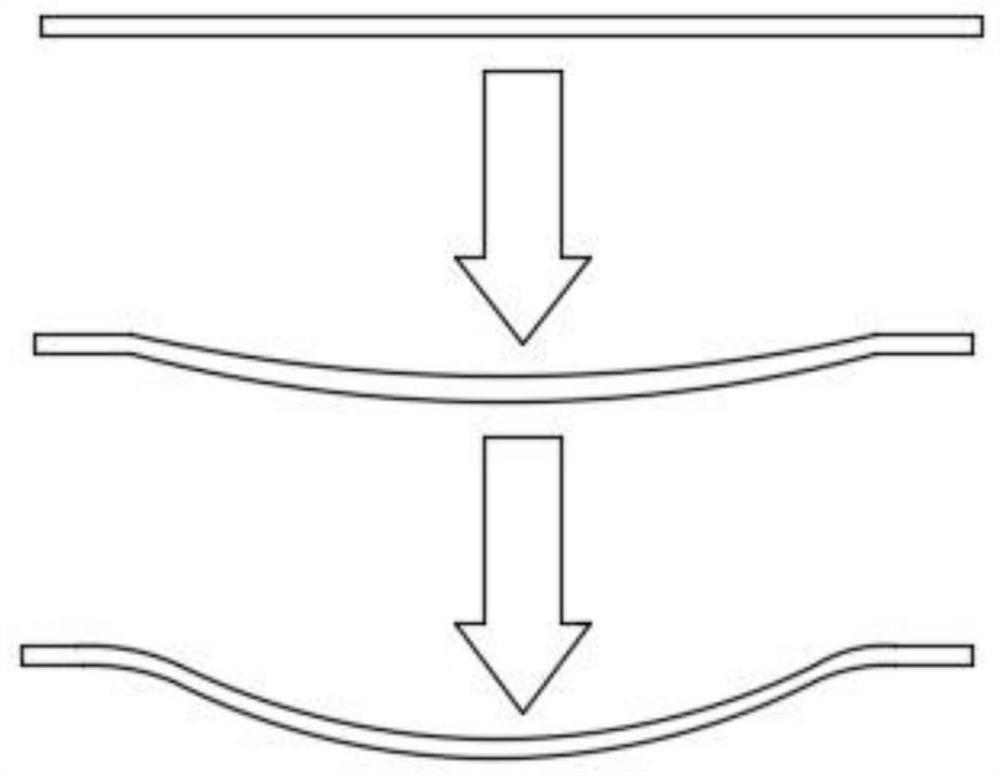

[0017] (3) Place the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com