Method for reinforcing concealed tunnel

A technology of tunneling and underground excavation, used in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of water and sand gushing, high site environment requirements, mud loss, etc., to reduce the probability of hole collapse, improve filling quality, and block The effect of mud loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

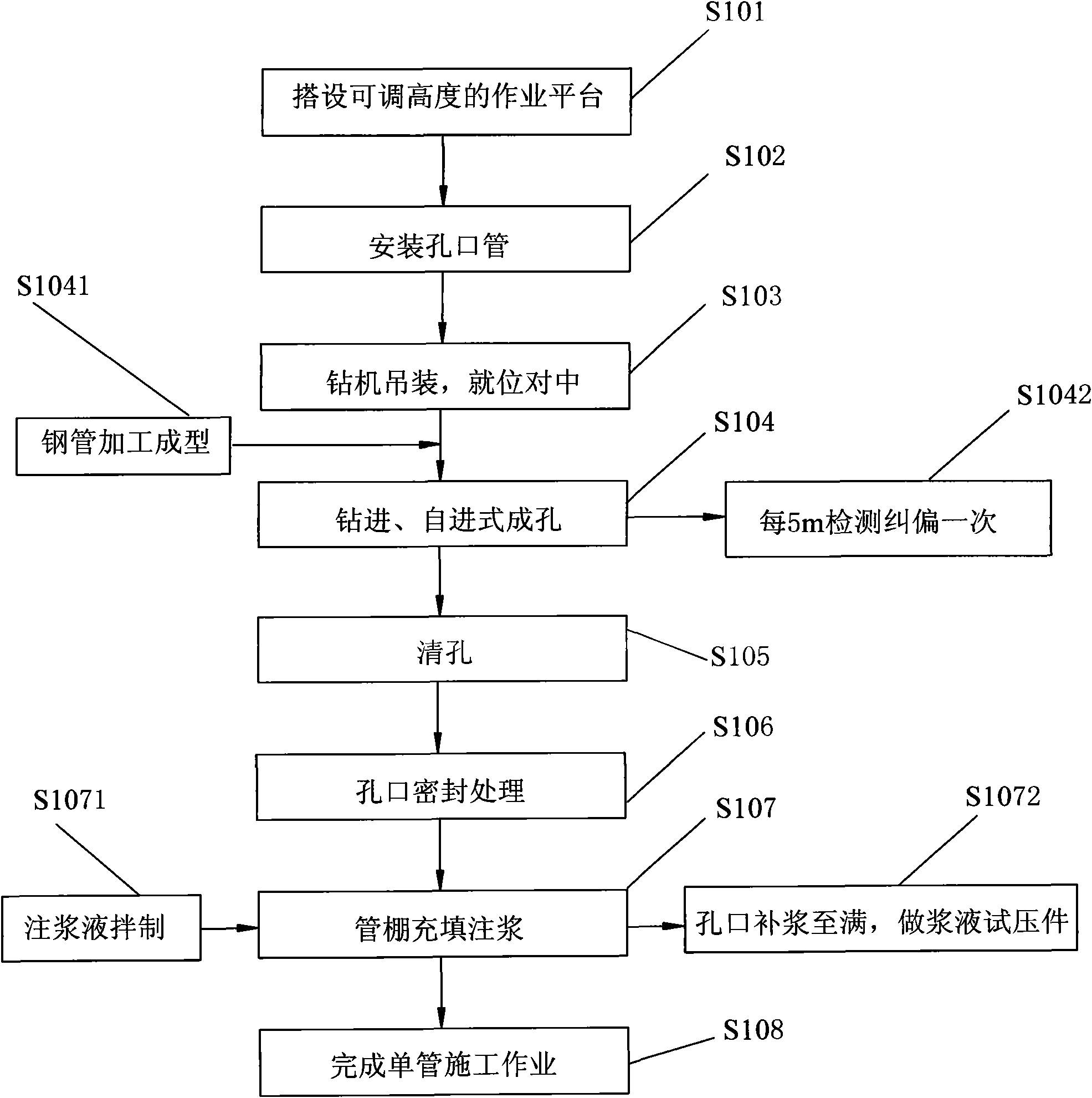

[0042] Such as figure 1 As shown, the embodiment of the present invention provides a reinforcement method for underground excavation tunnels. Before the excavation of the tunnel, a pipe shed is constructed on the arch of the tunnel, and the pipe shed is reinforced by grouting. The method includes the following steps:

[0043] Step S101 , according to the design position of the tunnel arch and the design requirements of the construction of the pipe shed, build a height-adjustable working platform.

[0044] Step S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com