Waterproof window frame and mounting method thereof

A technology for window frames and installation strips, which is applied to windows/doors, sealing devices, and frame fixing, etc. It can solve the problems of rainwater easily infiltrating into walls, reduced sealing performance, and poor waterproof performance, and achieves convenient and flexible installation and disassembly, and waterproof performance Good, easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

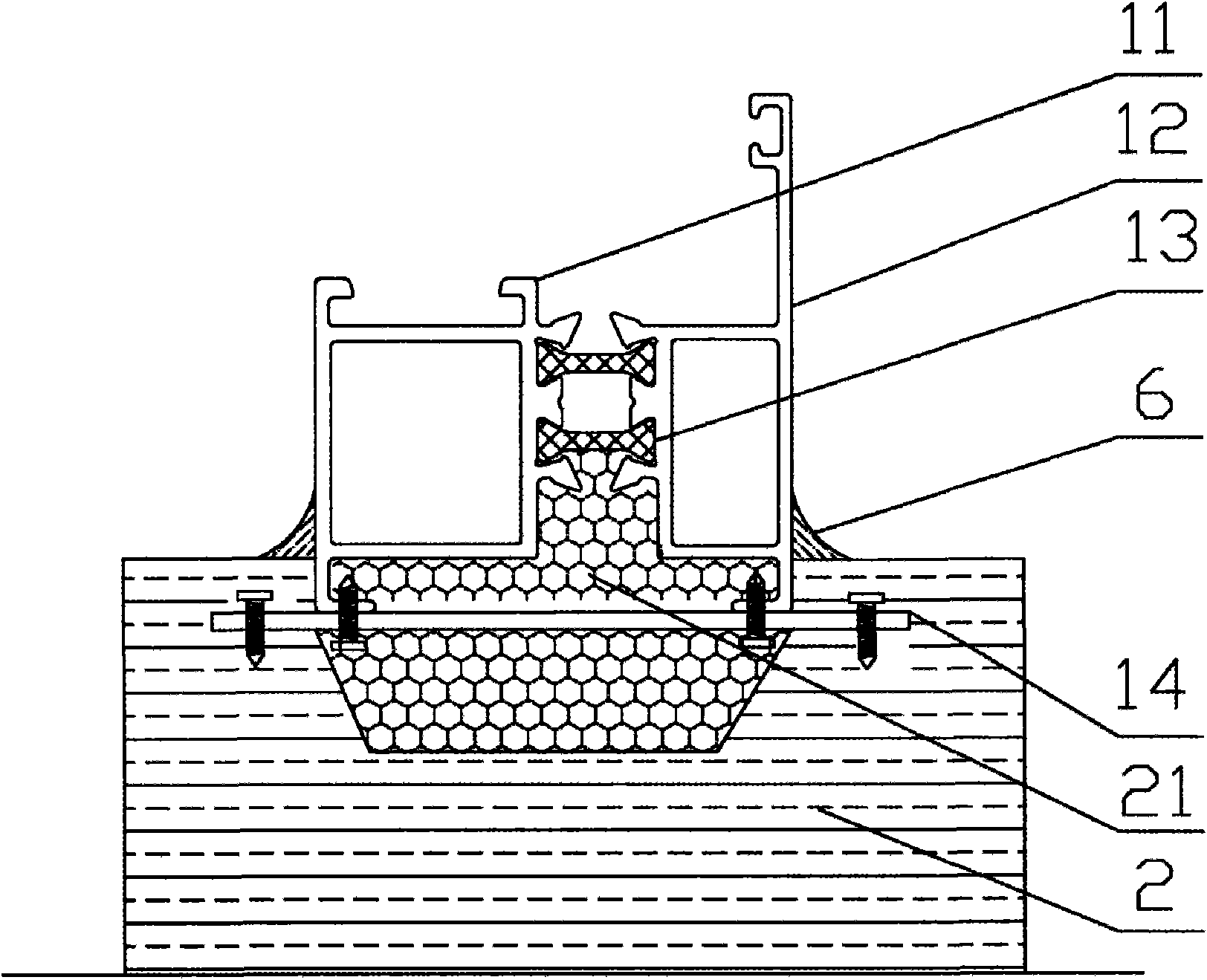

[0018] Embodiment 1 The first structure of the window frame of the present invention

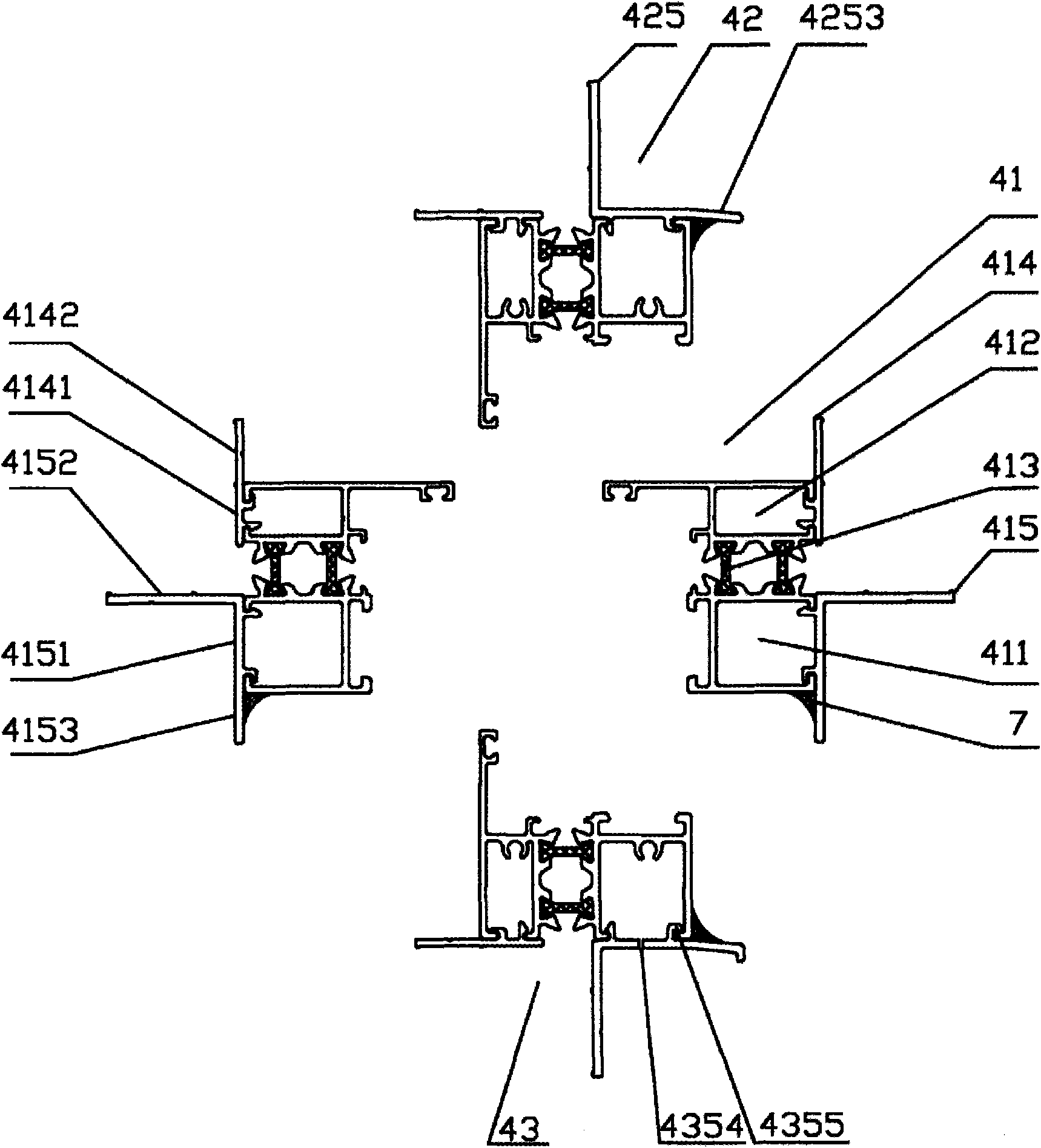

[0019] In this embodiment, the profile section of the window frame is as image 3 As shown, the window frame includes a mullion 41, an upper horizontal frame 42, and a lower horizontal frame 43, all of which are thermal insulation structures of broken bridges. Located on the indoor side, the outer frame and inner frame are hollow C-shaped. This window frame also comprises installation bar, comprises mullion outer frame 411, mullion inner frame 412, heat insulation strip 413, interior installation bar 414, vertical outer installation bar 415 as mullion 41, wherein, mullion outer frame 411 and mullion The inner frames 412 of the frame are all hollow C-shaped, and the C-shaped opening faces the wall to be installed during installation; the profile section of the inner installation bar 414 is linear, including an engaging part 4141 and an installing part 4142, and the engaging part 4141 is prov...

Embodiment 2

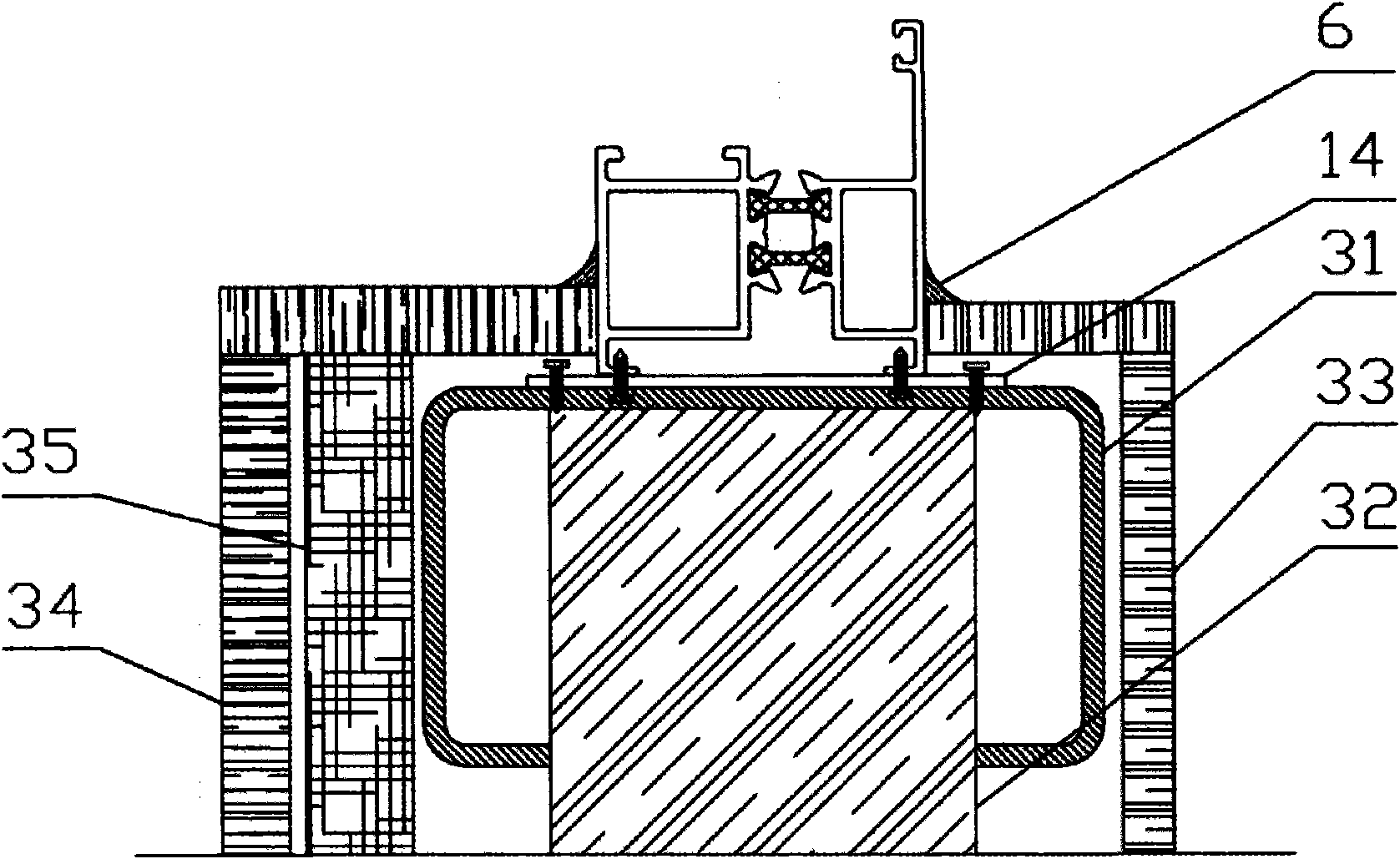

[0024] Embodiment 2 The method of installing the window frame of the present invention on a light steel structure wall

[0025] Such as Figure 5 As shown, when the window frame in Embodiment 1 of the present invention is installed on the light steel structure wall, the inner installation strip is fixed on the side of the C-shaped light steel keel 31 facing the window, and the outer installation strip is fixed on the C-shaped light steel keel 31 On the side facing the outside, the outer installation strip and the C-shaped light steel keel 31 are separated by a thermal insulation board 35 made of heat insulating material, and the outer wall panel 34 covers the outdoor wall, and the outer wall panel 34 and the outer installation strip The protruding outdoor part is sealed with a sealant 8, such as silicone sealant.

Embodiment 3

[0026] Embodiment 3 The second structure of the window frame of the present invention

[0027] Such as Figure 6As shown, in this embodiment, the structure of the outer frame and inner frame of the horizontal frame and the vertical frame and the inner installation strip is the same as that of Embodiment 1. The protruding outdoor part 5153 of the vertical outer mounting bar 515 of the vertical frame is U-shaped, and the protruding outdoor part 5252 of the upper outer mounting bar 525 of the upper horizontal frame is U-shaped and the side above it is inclined downward; The protruding outdoor portion 5353 of the mounting bar 535 is L-shaped and the side above it is inclined downward. In order to enhance the strength of the outer installation strip, the outer installation strip can be made into a closed structure, such as connecting the end of the vertical outer installation strip and the installation part of the upper outer installation strip with the end of the protruding outdo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com