Preparation of methane reactor

A technology for producing methane and reactors, which is applied in gas production bioreactors, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. and other problems, to achieve the effects of cleaning slag and maintaining safety, increasing the number of parasitics, and improving gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

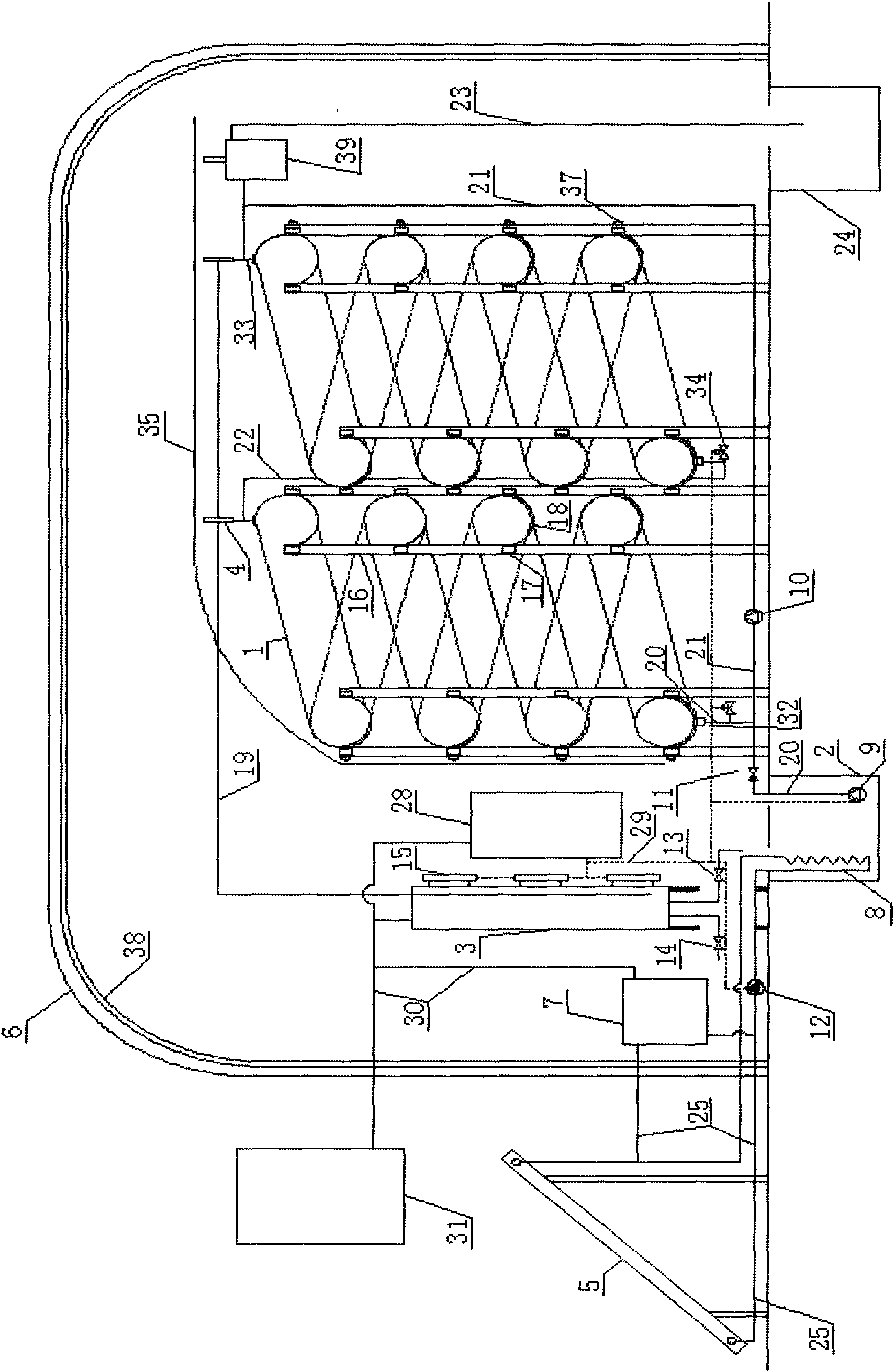

[0039] Example of the present invention is realized like this:

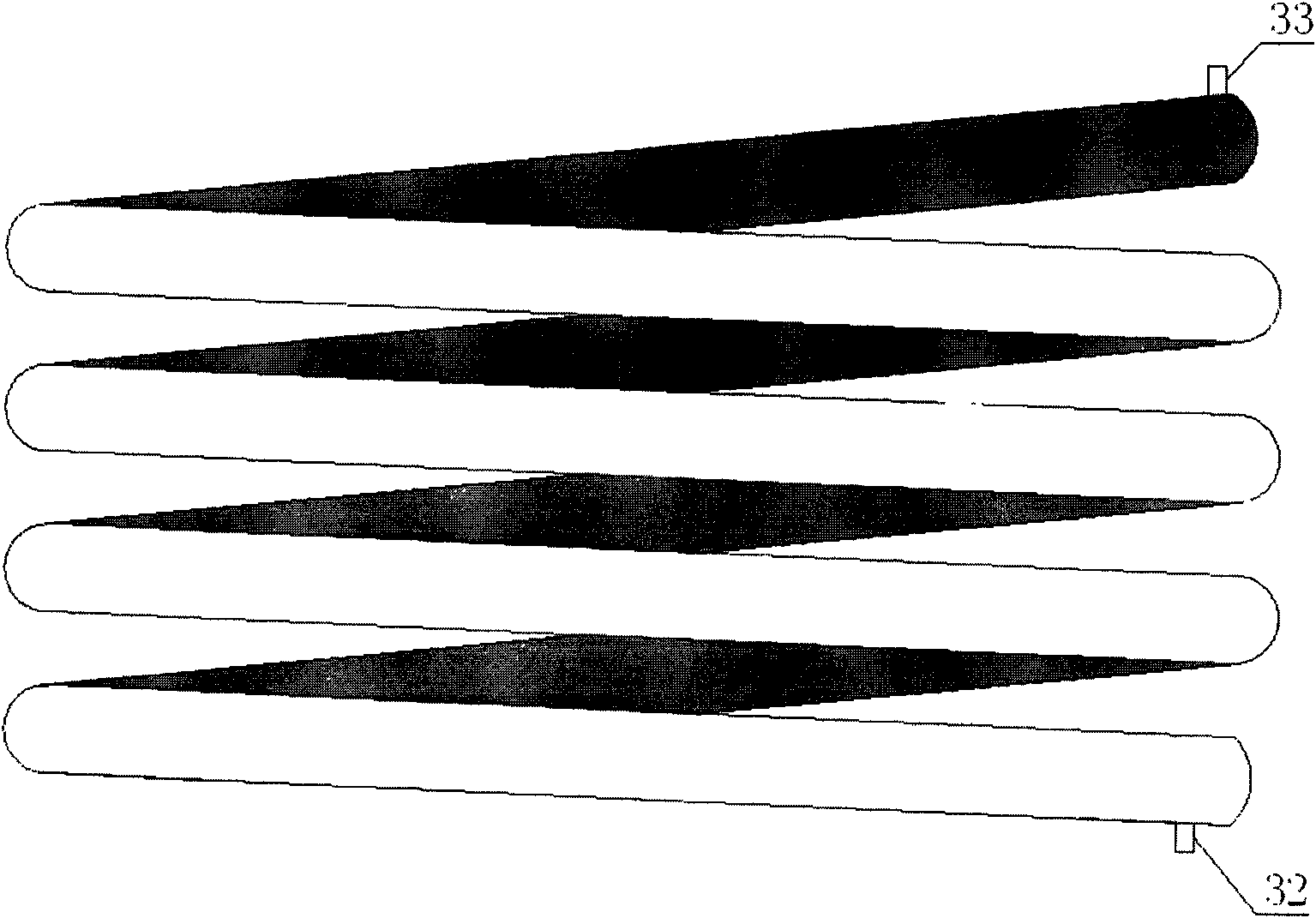

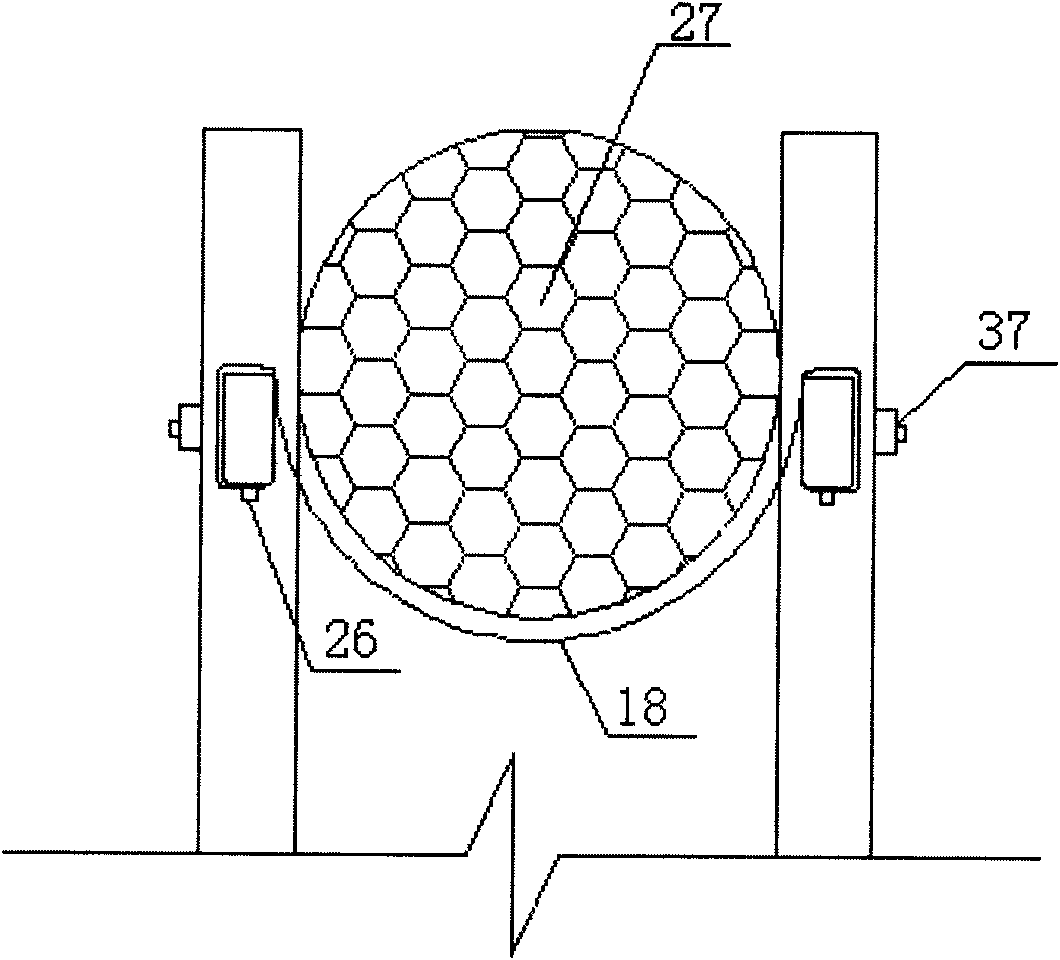

[0040] Methane reactor (1) of the present invention and supporting belt (18) are to form through high-frequency welder heat-sealing with the plastic cloth (as EVA coated cloth, PVC coated cloth, red mud plastic cloth etc.) bought in the market, And the methane reactor (1) is provided with inlet (32) and outlet (33), and the inside is also provided with honeycomb filler (27), and honeycomb filler (27) is also formed by heat-sealing with similar materials, supporting belt (18) Hanging hole (36) is drilled on. The carbon dioxide converter (3) is made by welding or bonding glass pipes or glass steel pipes. The gas-water separator (4) is made by hot-melt welding of plastic pipes (such as pipes such as PVC pipes, PE pipes, and PPR pipes). Support (16) and drag frame (17) are made with the steel pipe blanking, drilling, galvanizing bought in the market, and drag frame (17) is provided with hanger (26). These products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com