Method for preparing radar absorbing materials with hide glue fibril

A radar absorbing material and skin collagen technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsuitable paint use, limited wide application, loss of wave absorbing effect, etc., and achieve strong absorption capacity and strong wave absorption. performance, effect of absorbing frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After removing hair and non-collagen components, the cowhide is crushed, washed, treated with NaAc-Hac buffer solution of pH 4.2 for 6 hours, and then vacuum-dried at 40°C for 12 hours to obtain hide collagen fibers with a particle size of 0.2-2.0 mm.

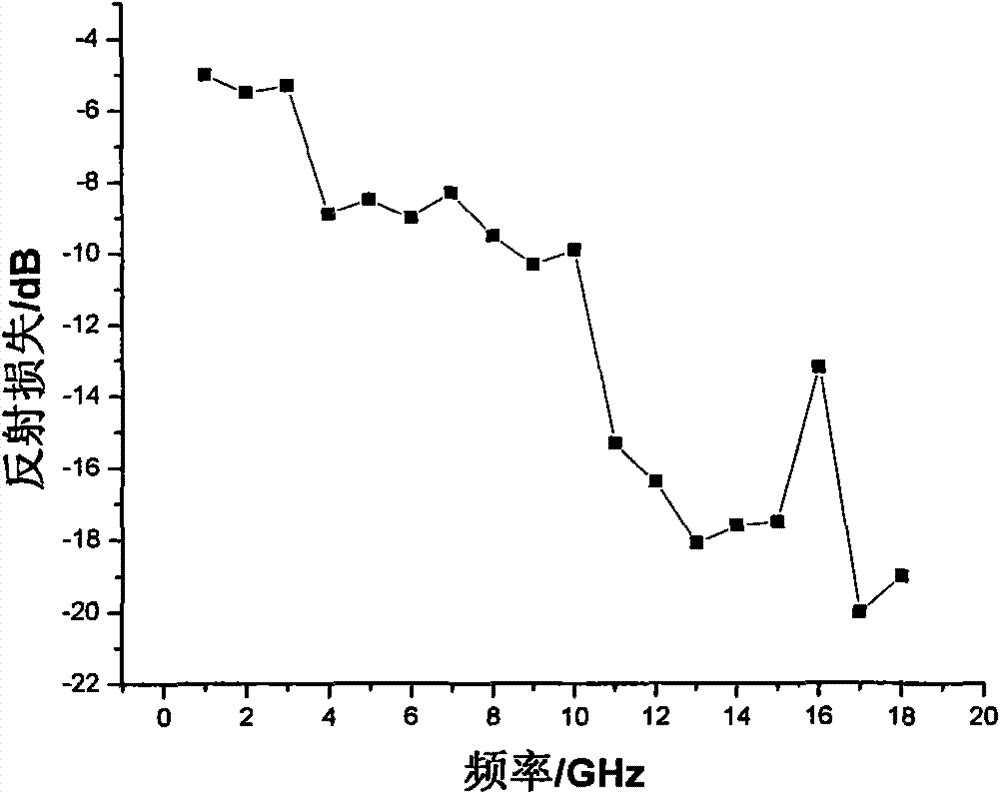

[0027] Add 50 grams of the obtained skin collagen fibers and 800 grams of absolute ethanol into a reaction kettle with a stirrer, a thermometer and a reflux condenser, adjust the pH to 8.0, then add 50 grams of salicylaldehyde, heat up and stir at 50°C React for 6 hours, then add 55 grams of ferric chloride, continue to stir and react at 50°C for 3 hours, and finally vacuum-dry the reactant at 50°C for 14 hours to obtain salicylaldehyde and Fe(III)-modified bovine collagen fibers Fe-Sa-CF radar absorbing material.

Embodiment 2

[0029] Wash waste pigskin scraps, crush and wash them, treat them with NaAc-Hac buffer solution with pH 4.2 for 6 hours, and then dry them under vacuum at 40°C for 12 hours to obtain skin collagen fibers with a particle size of 0.2-2.0 mm .

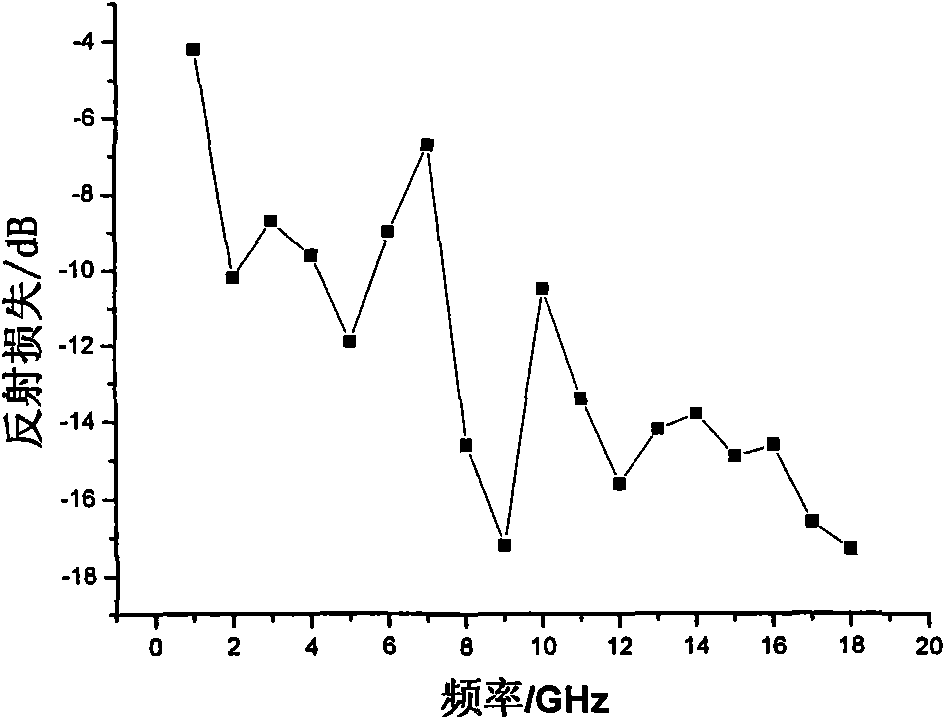

[0030] Add 50 grams of the obtained skin collagen fibers and 800 grams of absolute ethanol into a reaction kettle with a stirrer, a thermometer and a reflux condenser, adjust the pH to 10.0, then add 50 grams of salicylaldehyde, heat up and stir at 60°C React for 2 hours, then add 34 grams of silver nitrate, continue to stir and react at 60°C for 2 hours, and finally dry the reactant in vacuum at 60°C for 12 hours to obtain salicylaldehyde and Ag(I)-modified pigskin collagen fibers Ag -Sa-CF radar absorbing material.

Embodiment 3

[0032] Remove the hair and non-collagen components from the pigskin, crush and wash it, treat it with NaAc-Hac buffer solution with pH 4.2 for 6 hours, and then dry it under vacuum at 40°C for 12 hours to obtain skin collagen fibers with a particle size of 0.2-2.0 mm .

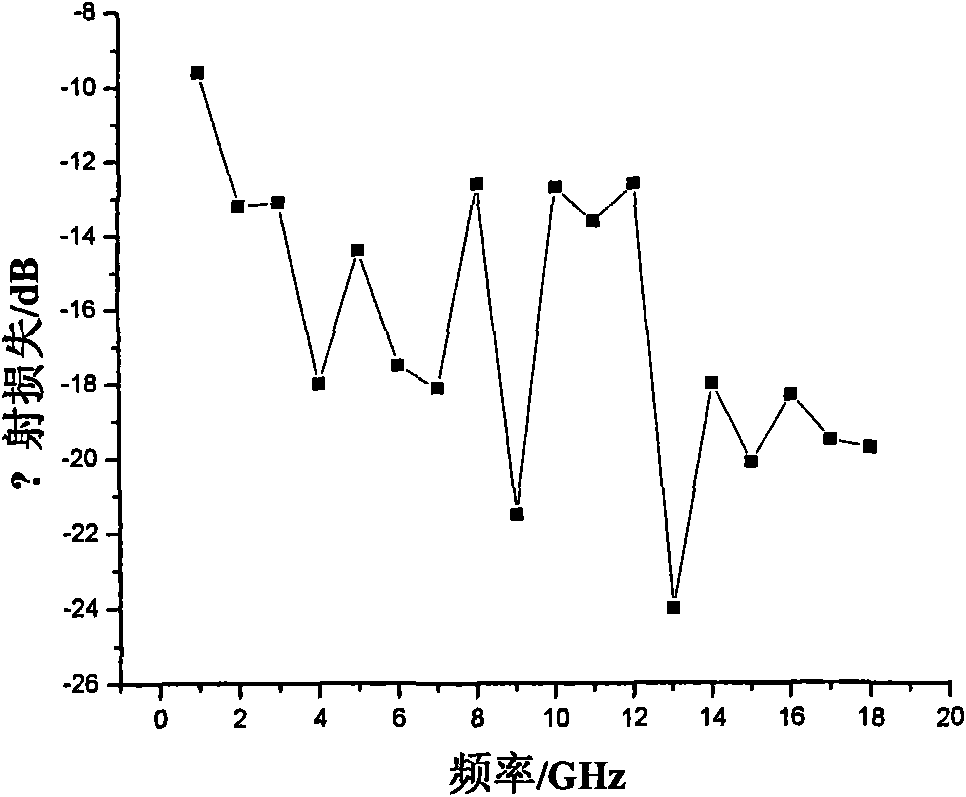

[0033] Add 50 grams of the obtained skin collagen fibers and 900 grams of absolute ethanol into a reaction kettle with a stirrer, a thermometer and a reflux condenser, adjust the pH to 9.0, then add 40 grams of glutaraldehyde, heat up and stir at 40°C React for 8 hours, then add 55 grams of ferric chloride, continue to stir and react at 40°C for 5 hours, and finally dry the reactant in vacuum at 40°C for 16 hours to obtain glutaraldehyde and Fe(III)-modified pigskin collagen Fiber Fe-Gl-CF radar absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com