Organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as preparation and application

A technology of phosphating titanium dioxide and titanium dioxide, which is applied in the treatment of dyed low molecular organic compounds, fibrous fillers, electrochemical generators, etc., to achieve the effects of rich raw material sources, uniform and controllable particle size, and high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

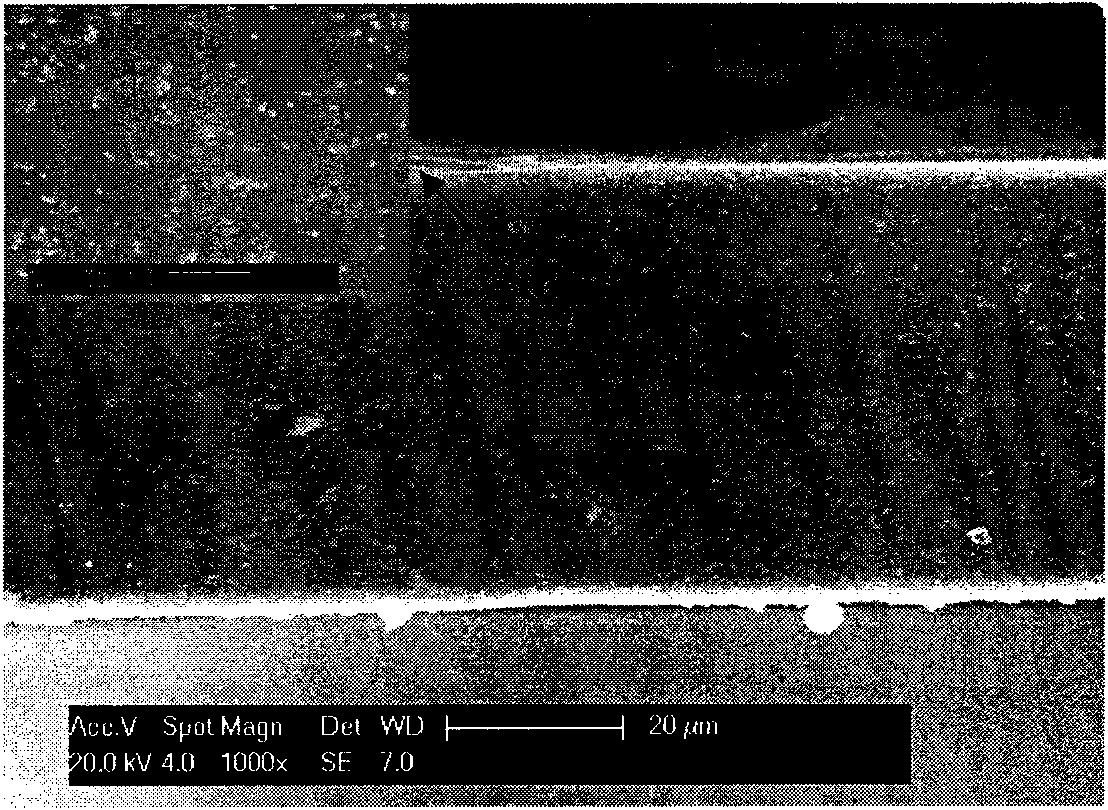

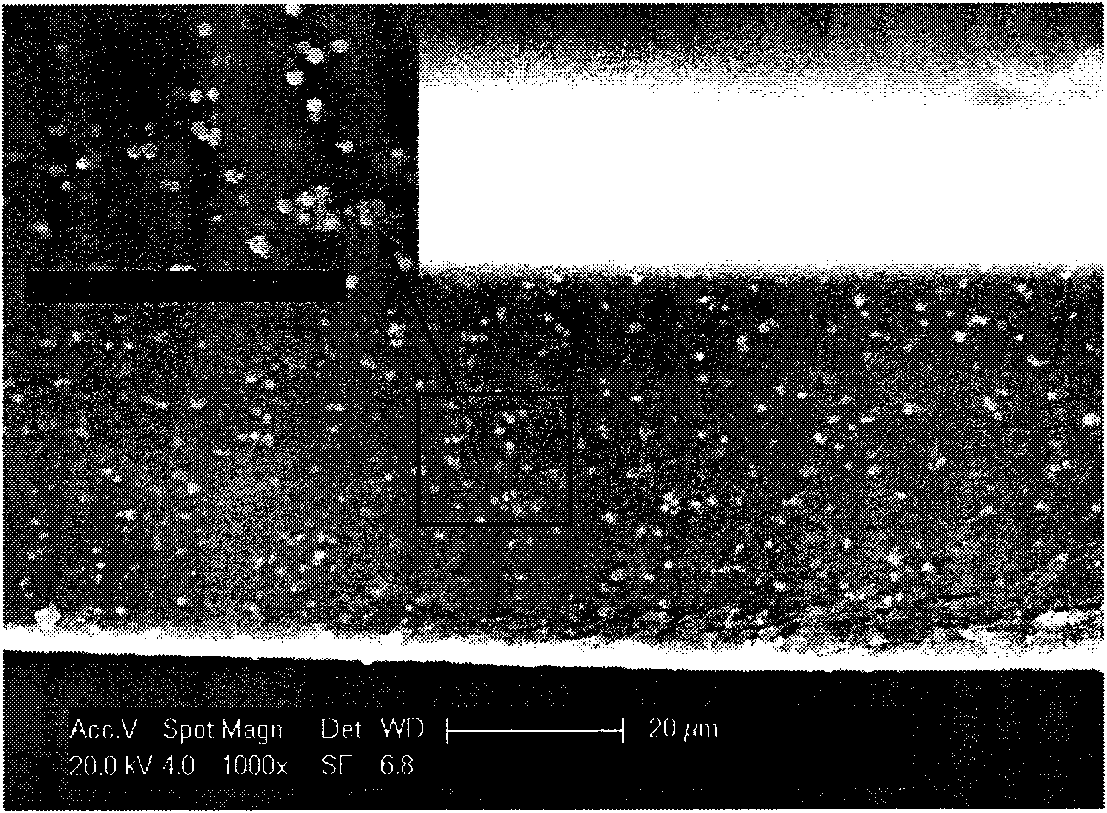

Image

Examples

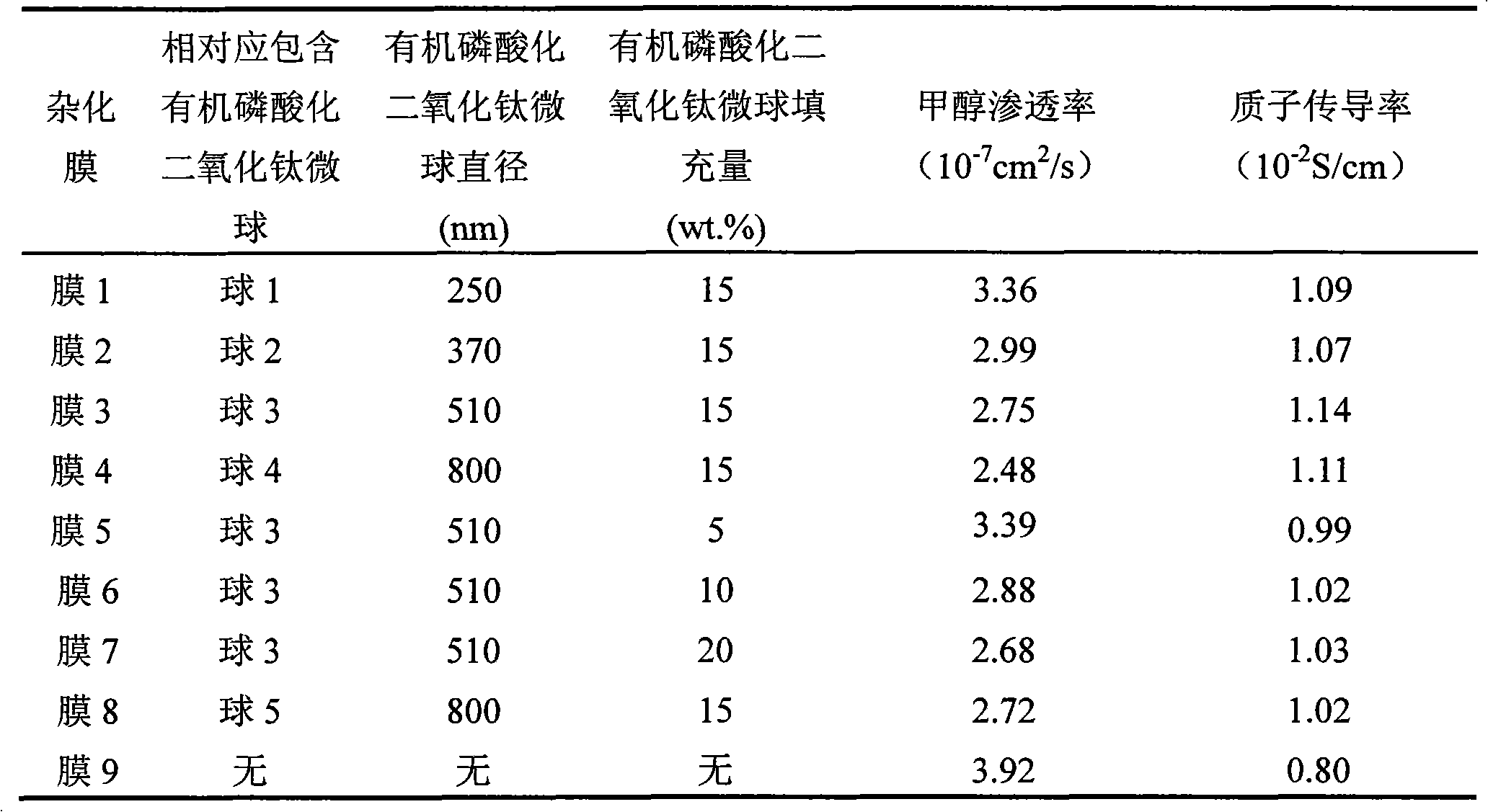

Embodiment 1

[0018] At room temperature, add 6.81 g of butyl titanate to 107 g of ethylene glycol, and stir for 8 hours under the protection of nitrogen, then pour the above mixed solution of butyl titanate and ethylene glycol into an aqueous solution of acetone containing 0.3 wt % of water , control the concentration of butyl titanate in acetone to 0.01M, stir for 1h, let stand and age for 0.5h to produce a white precipitate, wash the precipitate repeatedly with deionized water and ethanol for 5 times, and dry at 80°C to obtain titanium dioxide Microspheres; at room temperature, 0.5g titanium microspheres were added to 30mL of 10wt% aminotrimethylenephosphonic acid (ATMP) aqueous solution, mechanically stirred for 12h, and then washed with deionized water until the supernatant Ph was neutral, Dry at 80° C. to obtain organophosphorylated titanium dioxide microspheres (sphere 1). The diameter of the ball 1 is about 250 nm.

[0019] Dissolve 1.0g of glacial acetic acid in 50mL of water to m...

Embodiment 2

[0022] At room temperature, add 6.81 g of butyl titanate to 107 g of ethylene glycol, and stir for 8 hours under the protection of nitrogen, then pour the above mixed solution of butyl titanate and ethylene glycol into an aqueous solution of acetone containing 0.3 wt % of water , control the concentration of butyl titanate in acetone to 0.03M, stir for 1h, let stand and age for 0.5h to produce a white precipitate, wash the precipitate with deionized water and ethanol repeatedly for 5 times, and dry at 80°C to obtain titanium dioxide Microspheres; at room temperature, 0.5g titanium microspheres were added to 30mL of 10wt% aminotrimethylenephosphonic acid (ATMP) aqueous solution, mechanically stirred for 12h, and then washed with deionized water until the supernatant Ph was neutral, Dry at 80° C. to obtain organophosphorylated titanium dioxide microspheres (sphere 2). The diameter of the ball 2 is about 370 nm.

[0023] Dissolve 1.0g of glacial acetic acid in 50mL of water to m...

Embodiment 3

[0025]At room temperature, add 6.81 g of butyl titanate to 107 g of ethylene glycol, and stir for 8 hours under the protection of nitrogen, then pour the above mixed solution of butyl titanate and ethylene glycol into an aqueous solution of acetone containing 0.3 wt % of water , control the concentration of butyl titanate in acetone to 0.05M, stir for 1h, let stand and age for 0.5h to produce a white precipitate, wash the precipitate with deionized water and ethanol repeatedly for 5 times, and dry at 80°C to obtain titanium dioxide Microspheres; at room temperature, 0.5g titanium microspheres were added to 30mL of 10wt% aminotrimethylenephosphonic acid (ATMP) aqueous solution, mechanically stirred for 12h, and then washed with deionized water until the supernatant Ph was neutral, Dry at 80° C. to obtain organophosphorylated titanium dioxide microspheres (sphere 3). The diameter of the ball 3 is about 510 nm.

[0026] Dissolve 1.0g of glacial acetic acid in 50mL of water to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com