Method for preparing asphalt pavement material by adopting waste concrete

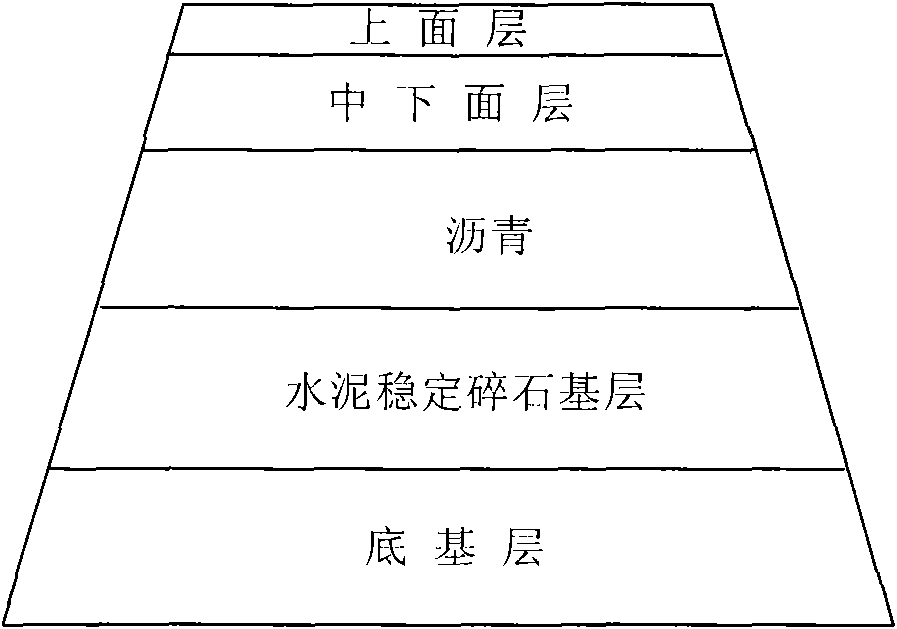

A technology for waste concrete and asphalt pavements, which can be applied to cohesive pavements, roads, roads and other directions paved on site, which can solve the problems of waste of resources and achieve the effects of improving utilization, promoting ecological balance, and promoting the protection of natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

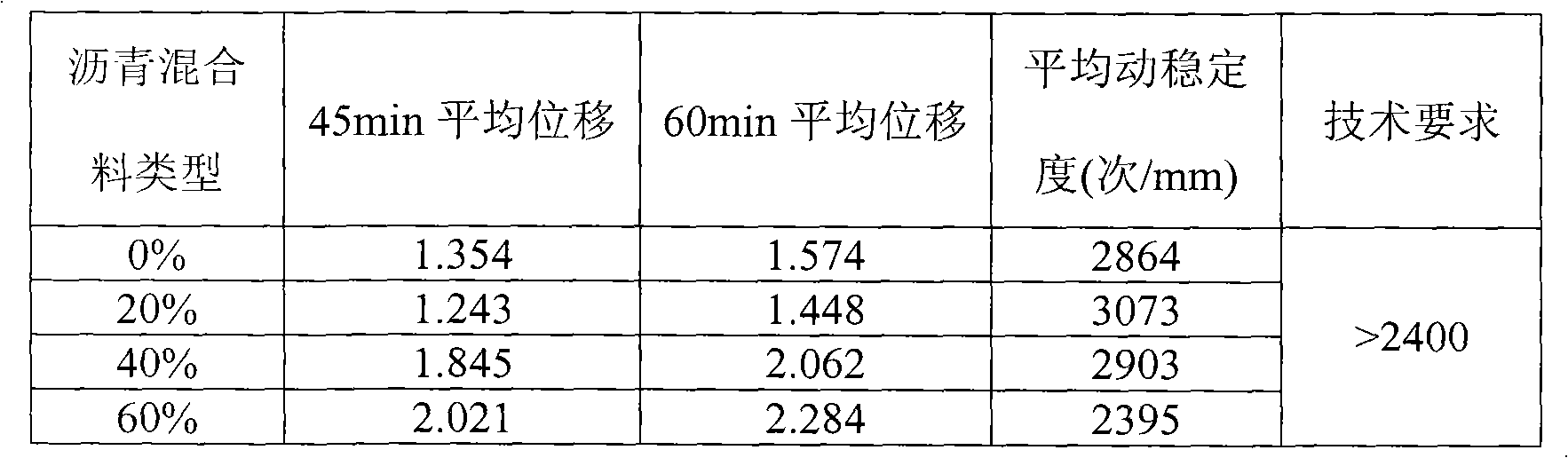

[0022] Embodiment 1: Take the configuration of densely graded asphalt concrete mixture AC-25 as an example.

[0023] Asphalt: use road petroleum asphalt 70# provided by Hubei Ezhou Keshi Asphalt Material Co., Ltd., and its quality requirements meet the "Technical Specifications for Road Asphalt Pavement Construction" (JTG F40-2004);

[0024] Aggregate: The natural aggregate is taken from crushed stone obtained by crushing limestone, and the recycled aggregate is taken from the waste concrete produced by cement concrete road renovation. The original cement 42.5 grade ordinary cement was used, and the cement concrete label was C30. After crushing, the recycled aggregates 1#, 2# and 3# that meet the requirements are obtained, and the graded particle size of the natural aggregate and the recycled aggregate is the same;

[0025] Filler: Use finely ground cement mortar powder, dry at 105°C for 3 to 4 hours before use;

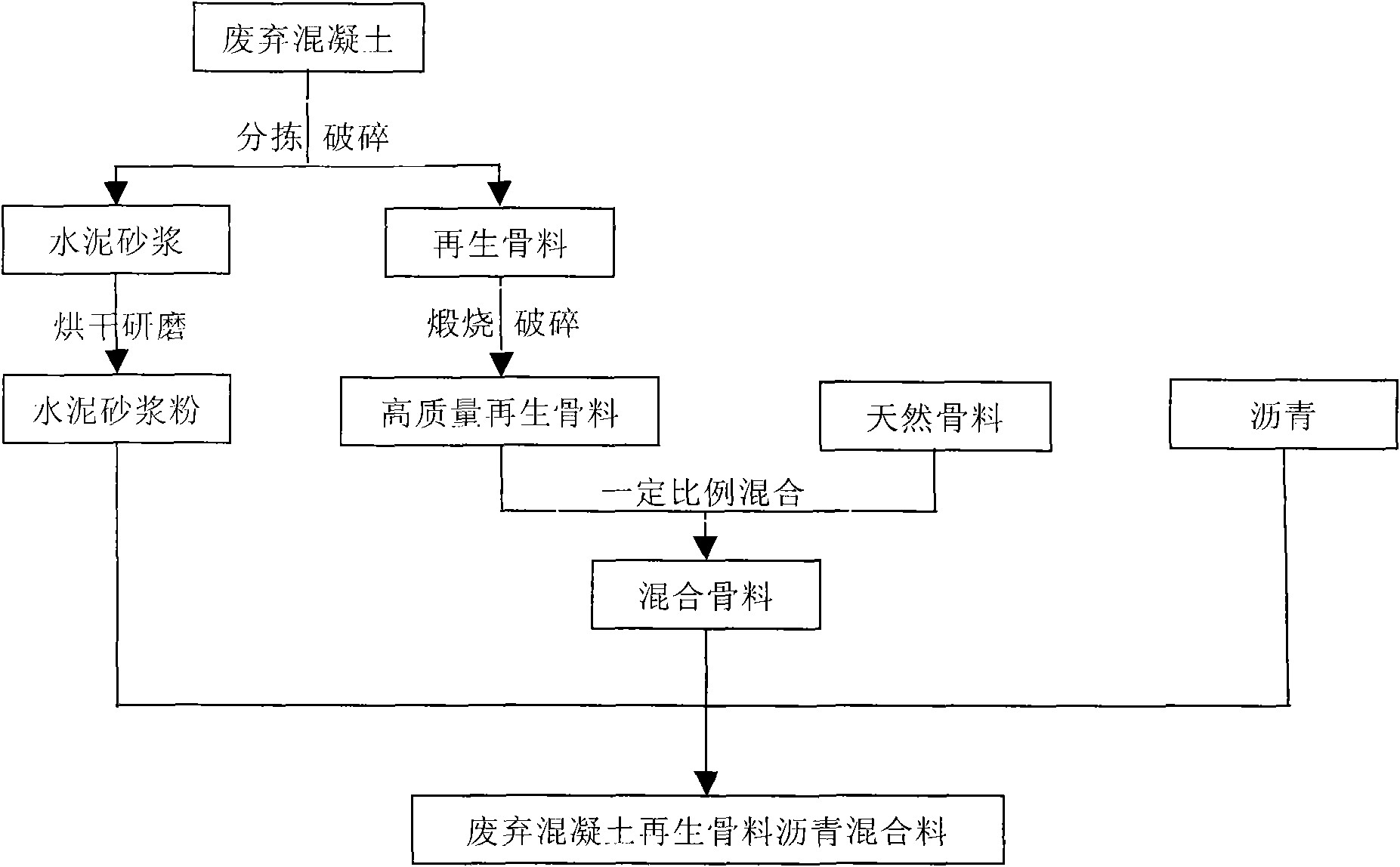

[0026] The preparation process of waste concrete recycled aggr...

Embodiment 2

[0028] Embodiment 2: Take the configuration of densely graded asphalt concrete mixture AC-20 as an example.

[0029] Asphalt: SBS modified asphalt provided by Hubei Ezhou Keshi Asphalt Material Co., Ltd. is used, and its quality requirements meet the "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40-2004);

[0030] Aggregate: The natural aggregate is taken from crushed stone obtained by crushing limestone, and the recycled aggregate is taken from the waste concrete produced by cement concrete road renovation. The original cement 42.5 grade ordinary cement was used, and the cement concrete label was C30. After crushing, the recycled aggregates 2# and 3# that meet the requirements are obtained, and the graded particle size of the natural aggregate and the recycled aggregate is the same;

[0031] Filler: Use finely ground cement mortar powder, dry at 105°C for 3 to 4 hours before use;

[0032] The preparation process of waste concrete recycled aggrega...

Embodiment 3

[0034] Embodiment 3: Take the configuration of ATB-25 asphalt stabilized gravel base course as an example.

[0035] Asphalt: use road petroleum asphalt 70# provided by Hubei Ezhou Keshi Asphalt Material Co., Ltd., and its quality requirements meet the "Technical Specifications for Road Asphalt Pavement Construction" (JTG F40-2004);

[0036] Aggregate: The natural aggregate is taken from crushed stone obtained by crushing limestone, and the recycled aggregate is taken from the waste concrete produced by cement concrete road renovation. The original cement 42.5 grade ordinary cement was used, and the cement concrete label was C30. After crushing, the recycled aggregates 1#, 2# and 3# that meet the requirements are obtained, and the graded particle size of the natural aggregate and the recycled aggregate is the same;

[0037] Filler: Use finely ground cement mortar powder, dry at 105°C for 3 to 4 hours before use;

[0038] The preparation process of waste concrete recycled aggre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com