Device for eliminating marks of plastic parts and method thereof

A technology for marking and plastic parts, which is applied in the field of devices and methods for clearing plastic parts marking, and can solve the problems of welding cloth texture, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

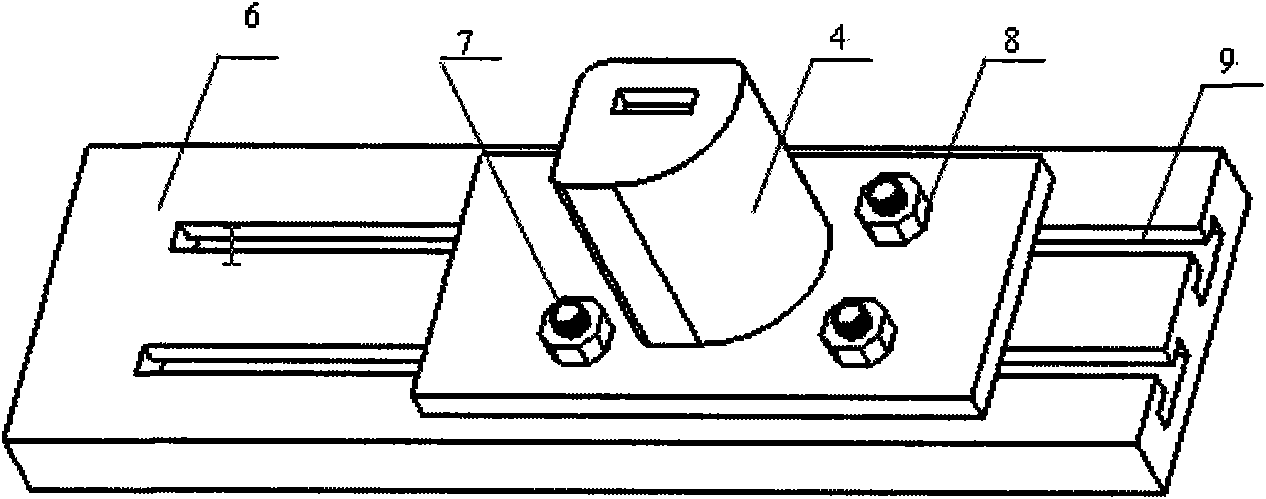

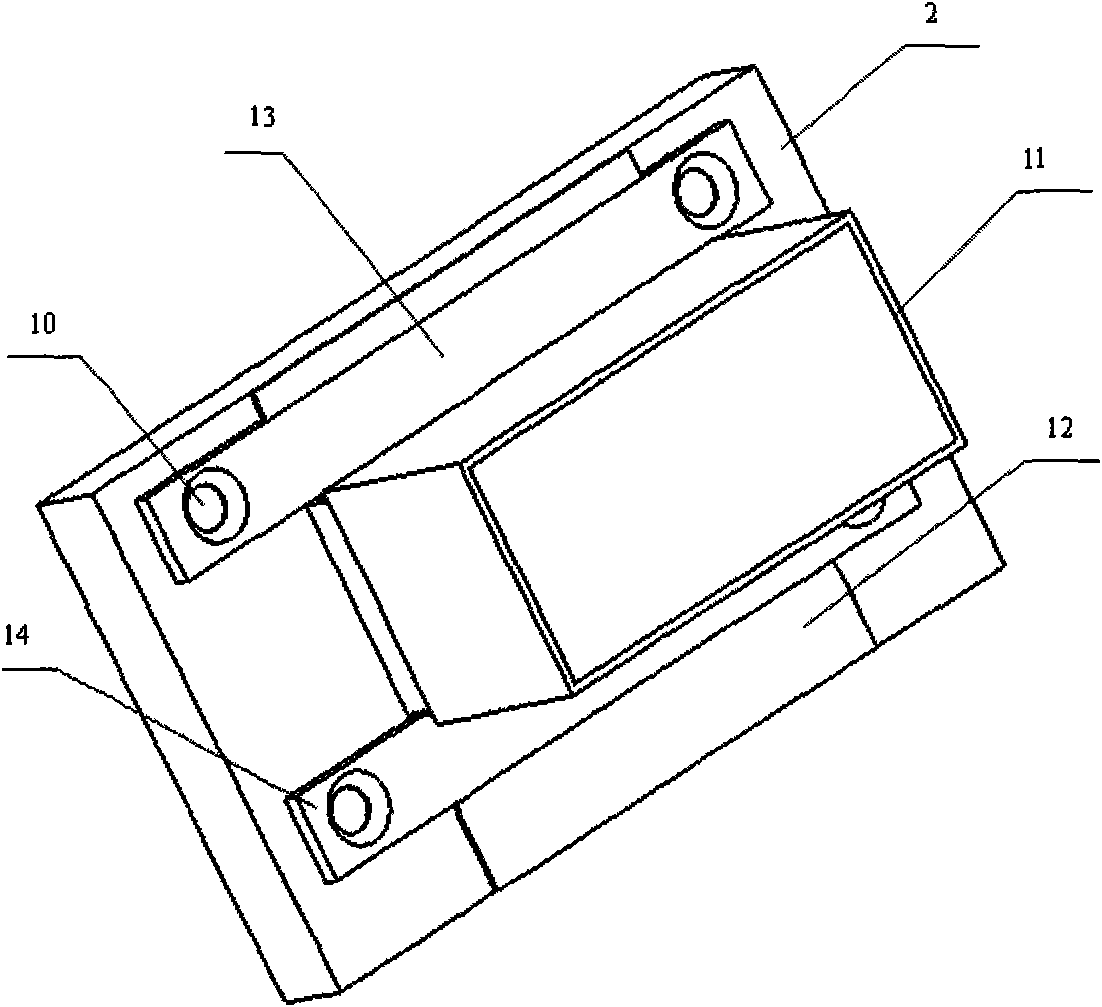

[0023] Embodiment: wrap the polytetrafluoroethylene film 12 on the welding head 2, and fix it by four countersunk screws 10 on the pressing piece 13 and the pressing piece 14, so that the pressing piece is close to the front side 16 and the rear side of the welding head, The aluminum silicate heat insulation sleeve 11 is covered on the film, so that the film 12 is tightly wrapped on the welding head 2 . Remove the welding head of the YDX-03E heat-sealing welding machine 1, and make the welding head 2 replace the original welding head of the YDX-03E heat-sealing welding machine 1 and fix the position. Fix the chute base 6 on the base of the YDX-03E heat-sealing welding machine 1, and move the four sliding screws 7 in the chute base 6 to pass through the threaded holes of the support table placed on the chute base 6 . Place the plastic part 5 on the support platform 4 with the logo facing upward. While manually pressing down the welding head 2 slightly, move the support table 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com