Self-propelled seeding, fertilizing and spraying combined operation machine

A combined working machine and self-propelled technology, used in fertilization devices, fertilizer and seeding equipment, agriculture, etc., can solve the problems of large turning radius of the headland, no spraying function, difficult field management, etc., and achieve a small turning radius of the headland. , Improve work efficiency, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

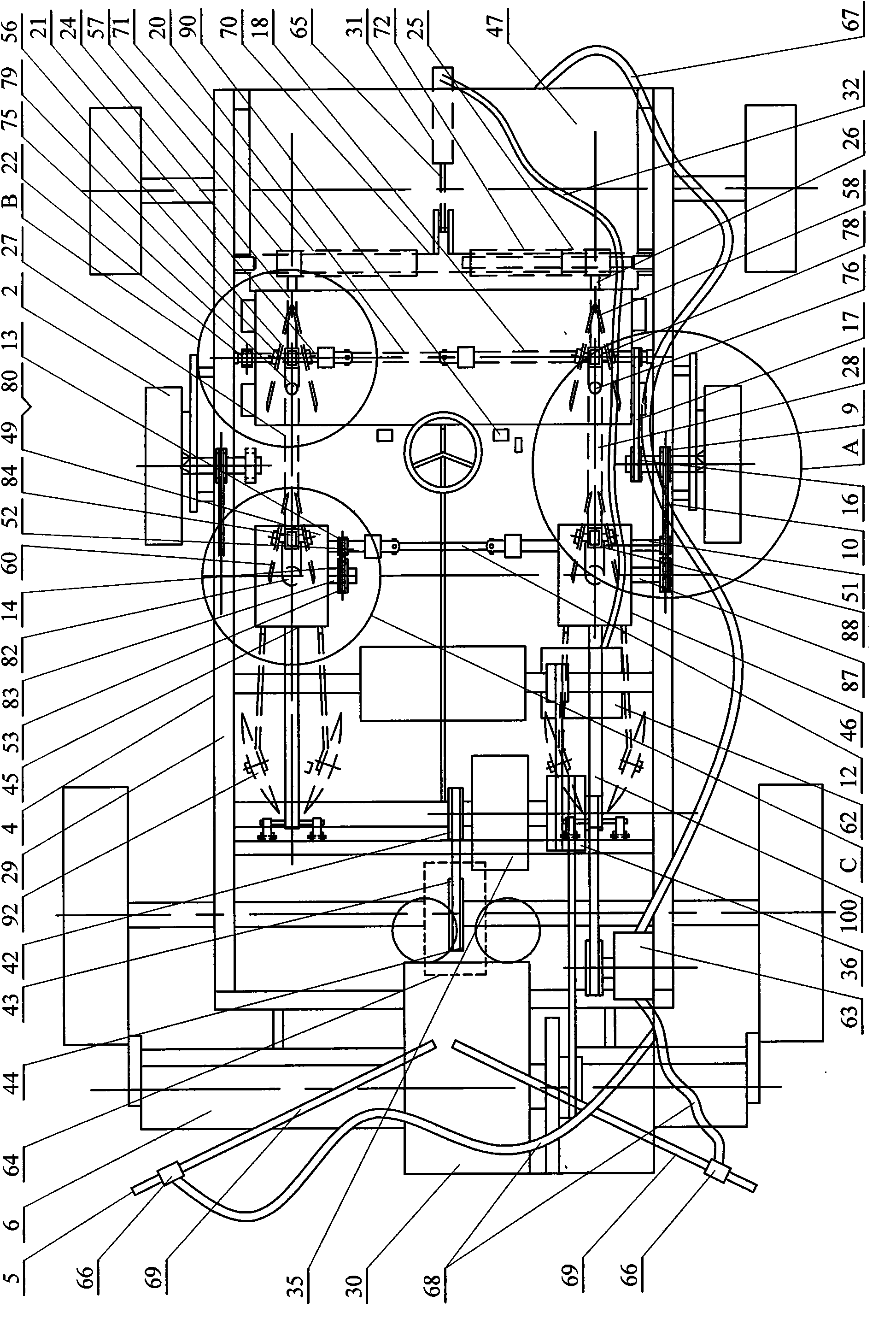

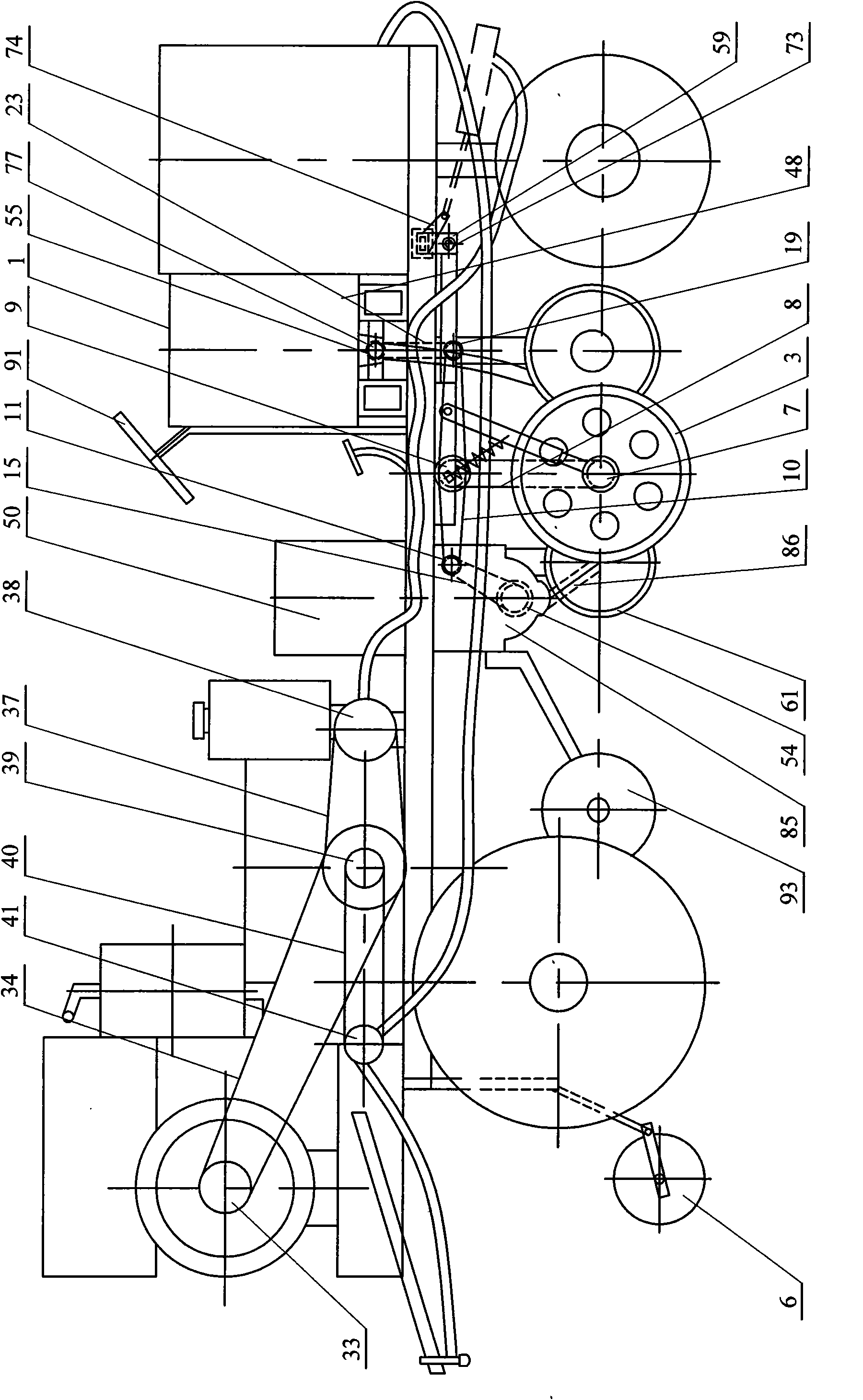

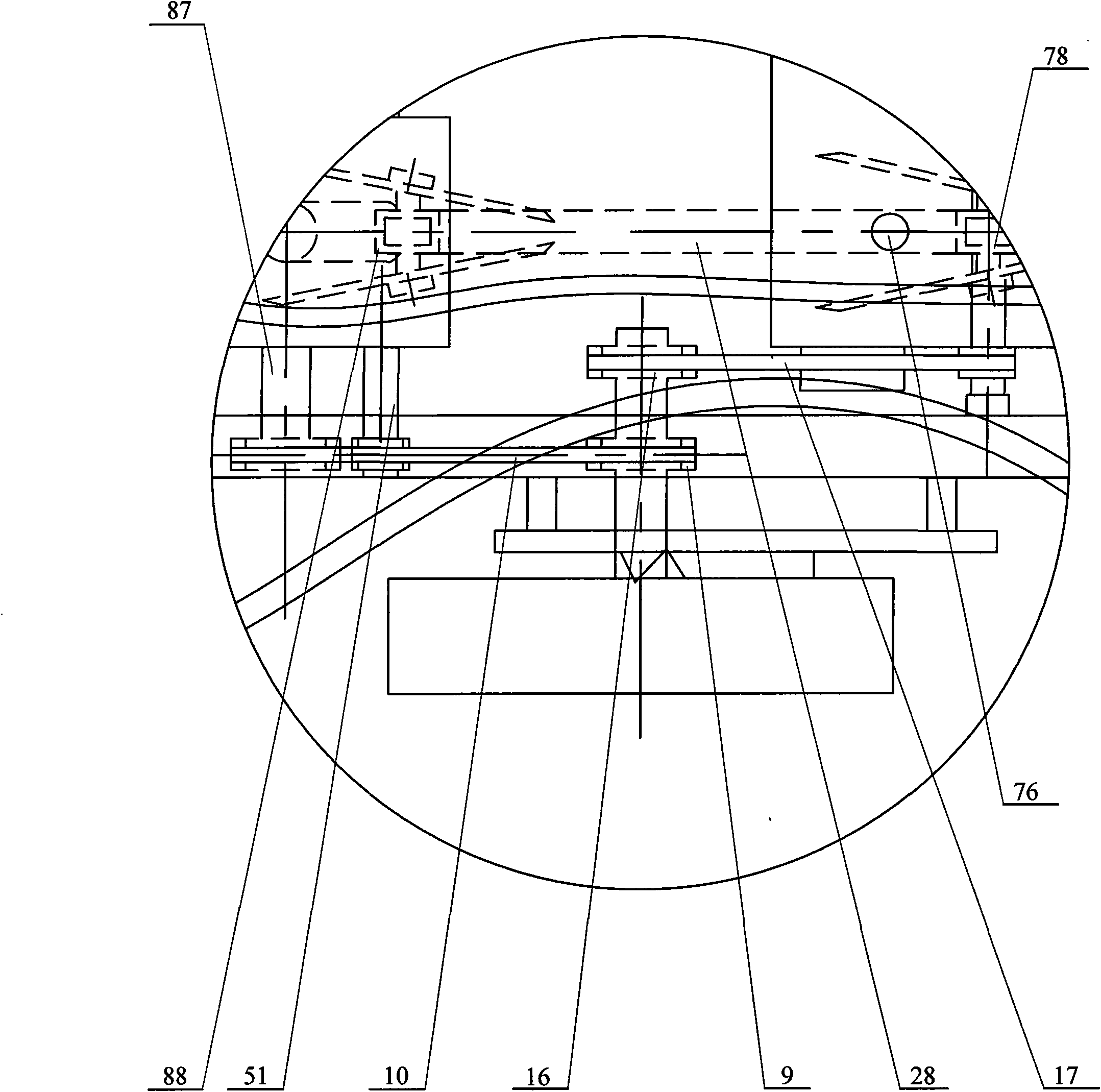

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the combined working machine of this embodiment comprises seeder, fertilizer spreader 1, left traveling wheel 2, right traveling wheel 3 and vehicle body 4; Described vehicle body 4 comprises vehicle frame 29, engine 30, oil cylinder 31, Pipeline 32, gearbox clutch 35, vehicle frame rear axle 64, brake mechanism 90 and steering travel mechanism 91; the combined operation machine also includes spraying machine 5, suppressor 6, driving sprocket 7, first chain 8, First transition sprocket 9, second chain 10, second transition sprocket 11, first universal joint drive shaft 12, third transition sprocket 13, third chain 14, fourth chain 15, fourth transition sprocket 16. Fifth chain 17, right shaft 18, fifth transition sprocket 19, second universal joint drive shaft 20, left shaft 21, sixth transition sprocket 22, sixth chain 23, left front beam 24, lateral position Adjusting device 25,...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, the medicine spraying machine 5 of this embodiment is made up of medicine box 47, medicine spray bar, two shower nozzles 66, the first medicine delivery pipe 67, two second medicine delivery pipes 68, medicine spray pump 63 and hydraulic pump 62; the spraying rod is composed of two spraying rods 69 arranged symmetrically along the longitudinal centerline of the vehicle frame 29, and each spraying rod 69 is equipped with a nozzle 66, and the liquid medicine outlet of the medicine box 47 passes through The first drug delivery tube 67 communicates with the input port of the drug spray pump 63 , and the output port of the drug spray pump 63 communicates with the corresponding spray heads 66 through two second drug delivery tubes 68 . Such an arrangement has a simple structure and is easy to install, and the distance between the two spray heads 66 can be adjusted according to the di...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 1 to Figure 5Describe this embodiment, the lateral position adjustment device 25 of this embodiment is made up of square beam 70, left side pipe 71, right side pipe 72, lead screw 73, connecting frame 74, left threaded sleeve 57 and right threaded sleeve 59; The two ends of square beam 70 are rotatably connected with vehicle frame 29, and described left side pipe 71 and right side pipe 72 are all sleeved on square beam 70 and are respectively slidably matched with square beam 70, and the lower end of left side pipe 71 is connected with left thread sleeve 57 is affixed, the lower end of the right side pipe 72 is fixedly connected with the right threaded sleeve 59, and one end of the screw 73 is contained in the left threaded sleeve 57 and the right threaded sleeve 59 and is threadedly connected with the two, the rear end of the connecting frame 74 It is obliquely fixed to the middle of the square beam 70 , and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com