Crankshaft rocker type speed reducer

A deceleration device and rocker arm type technology, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of difficult manufacturing, low transmission efficiency, and high production costs, and achieve easy implementation, improved transmission efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

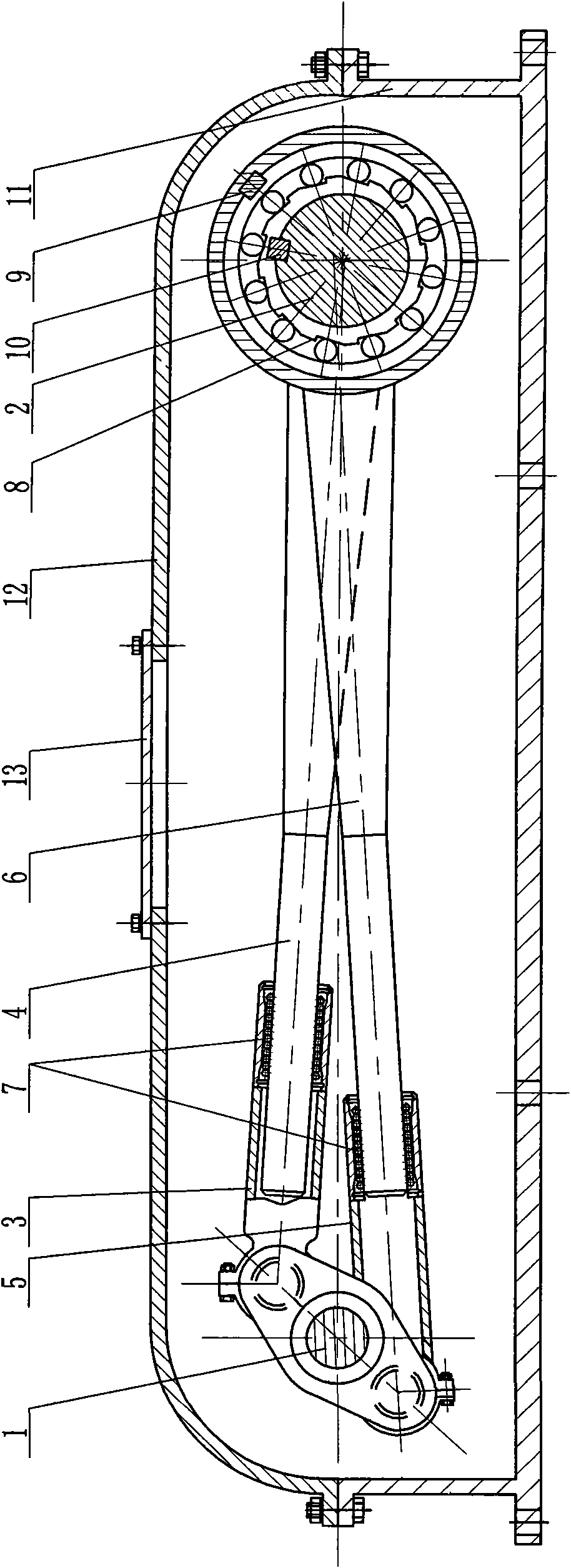

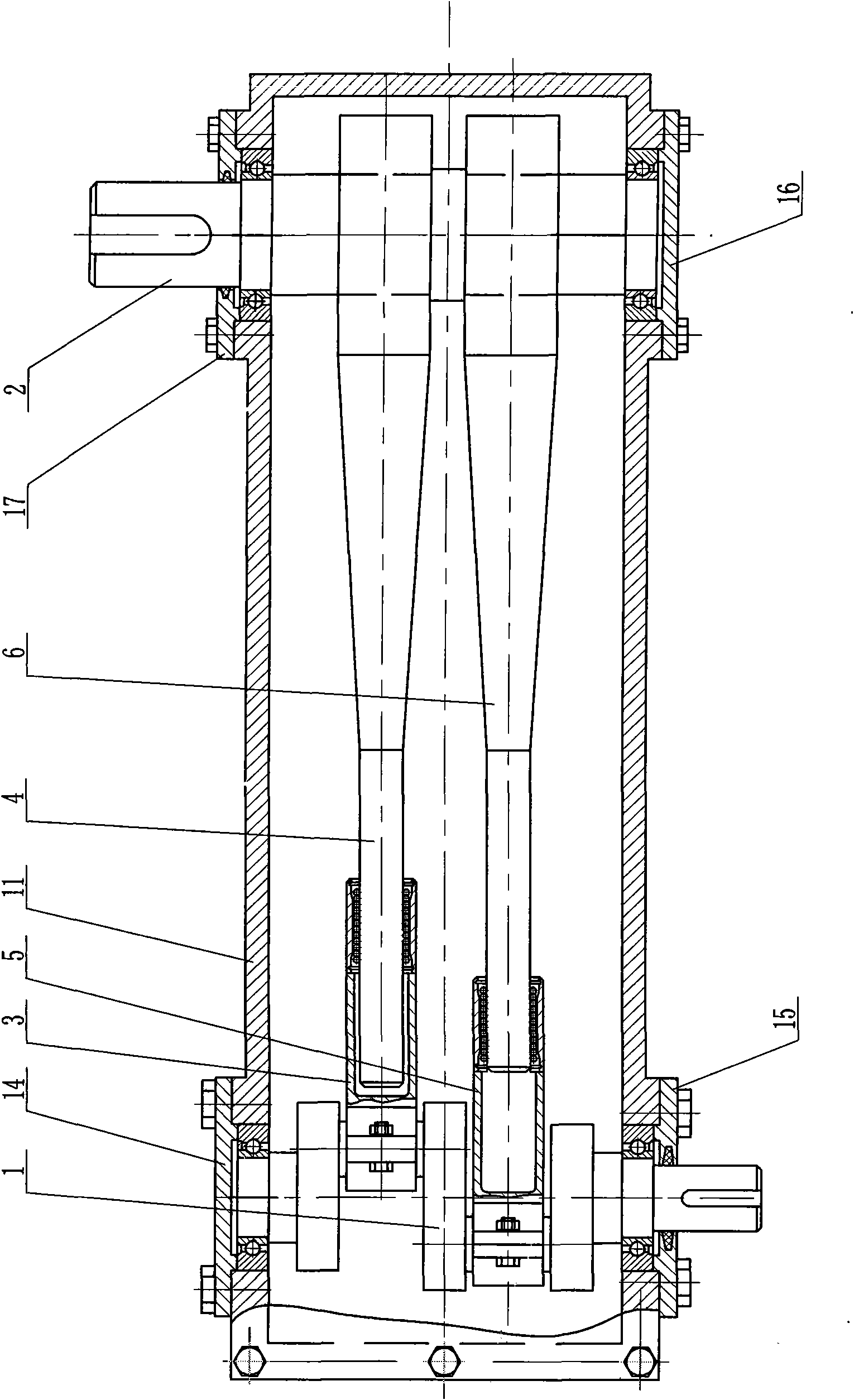

[0024] Such as figure 1 , figure 2 As shown, this embodiment consists of input shaft 1, output shaft 2, first link 3, first rocker arm 4, second link 5, second rocker arm 6, sliding bearing 7, ratchet wheel 8, first flat key 9. The second flat key 10, the box body seat 11, the box cover 12, the observation hole cover 13, the crankshaft blind cover 14, the crankshaft through cover 15, the output shaft blind cover 16, and the output shaft through cover 17 are composed of components. The box body base 11 and the box cover 12 are both box-shaped structures with one end open and the other closed. The open ends of the two are buckled together and fixed by bolts to form the box body of the deceleration device. An observation hole is opened in the center of the top of the box cover 12, the observation hole is sealed by the observation hole cover 13, and the observation hole cover 13 is fixed to the box cover 12 by bolts.

[0025] From figure 1 , figure 2 It can be seen that the input s...

Embodiment 2

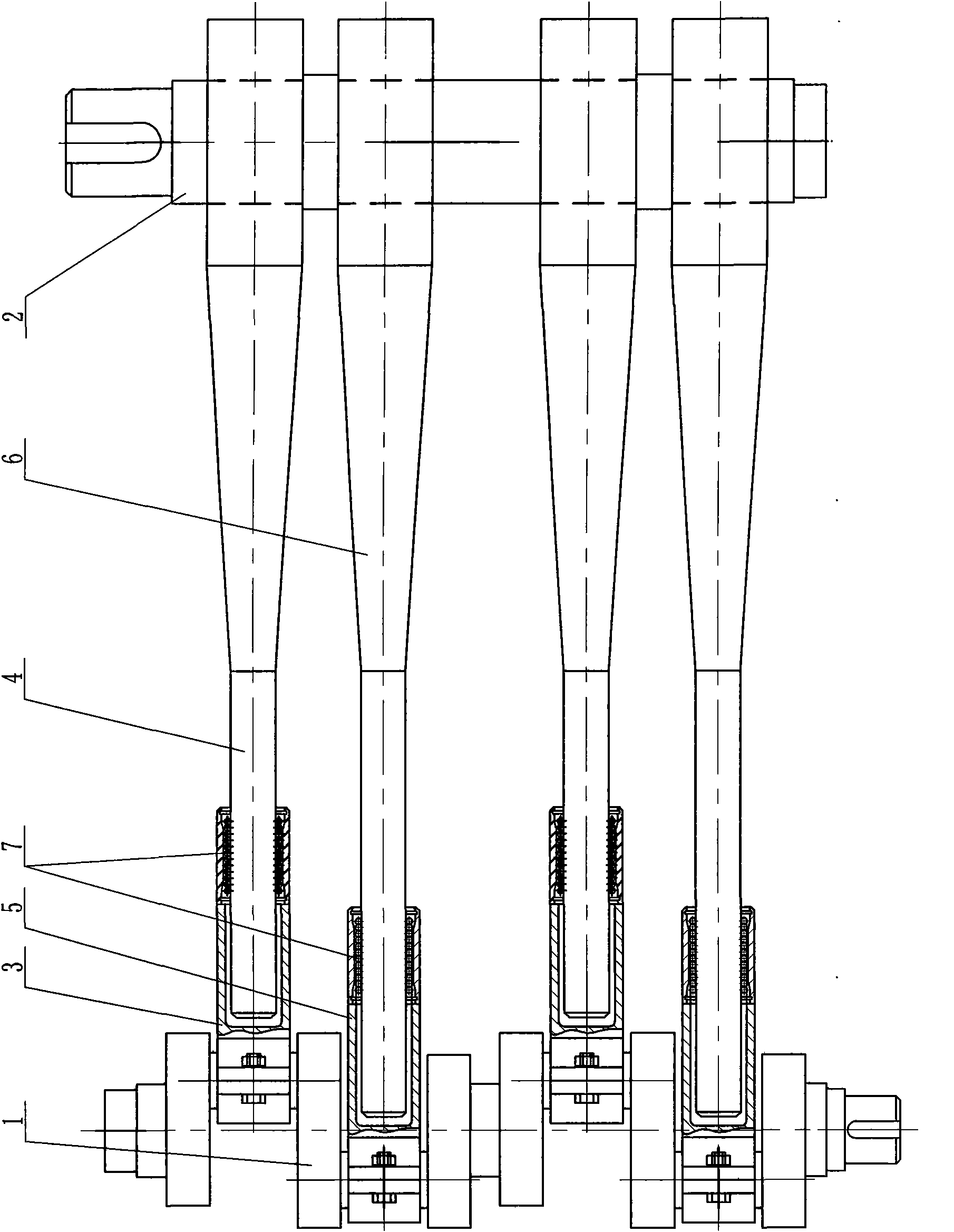

[0029] Such as image 3 As shown, there are two sets of crankshafts along the axial direction on the crankshaft, and each set of crankshafts is equipped with two sets of connecting rod, rocker arm and one-way device. The setting method of each group of cranks, and the connection relationship among the cranks, connecting rod, rocker arm and unidirectional device in each group are the same as those in the first embodiment, and will not be repeated here. In the same way, 3 groups or more than 3 groups of crankshafts can be arranged along the axial direction on the crankshaft, and a corresponding number of connecting rods, rocker arms and unidirectional devices can be equipped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com