Structure for lowering load of rotary compressor

A rotary compressor and load technology, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of reduced service life, mechanical wear, increased compressor load, reduced compressor performance and reliability, etc. problem, achieve the effect of reducing power, reducing mechanical wear and load, and improving performance and reliability

Inactive Publication Date: 2003-07-02

LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, in the above-mentioned rotary compressor, when the refrigerant gas is compressed, the end of the rolling piston 9 is in contact with the main bearing 7 and the auxiliary bearing 8, so that mechanical wear and an increase in the load of the compressor inevitably occur, resulting in a loss of performance of the compressor. and reduced reliability, thereby reducing service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0046] A contact surface of the rolling piston 51 and the main bearing 53 forms a groove 57a or 57c.

Embodiment 2

[0048] The contact surface of the rolling piston 51 and the auxiliary bearing 55 forms a groove 57b or 57d.

Embodiment 3

[0050] The contact surfaces of the rolling piston 51 with the main bearing 53 and the auxiliary bearing 55 form grooves 57a, 57b or 57c, 57d.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A structure for decreasing load of vortex-type compressor is composed of rolling piston, primary bearing and secondary bearing, and features that a recess is made on at least surface of them to decrease the contact area, so reducing friction and load.

Description

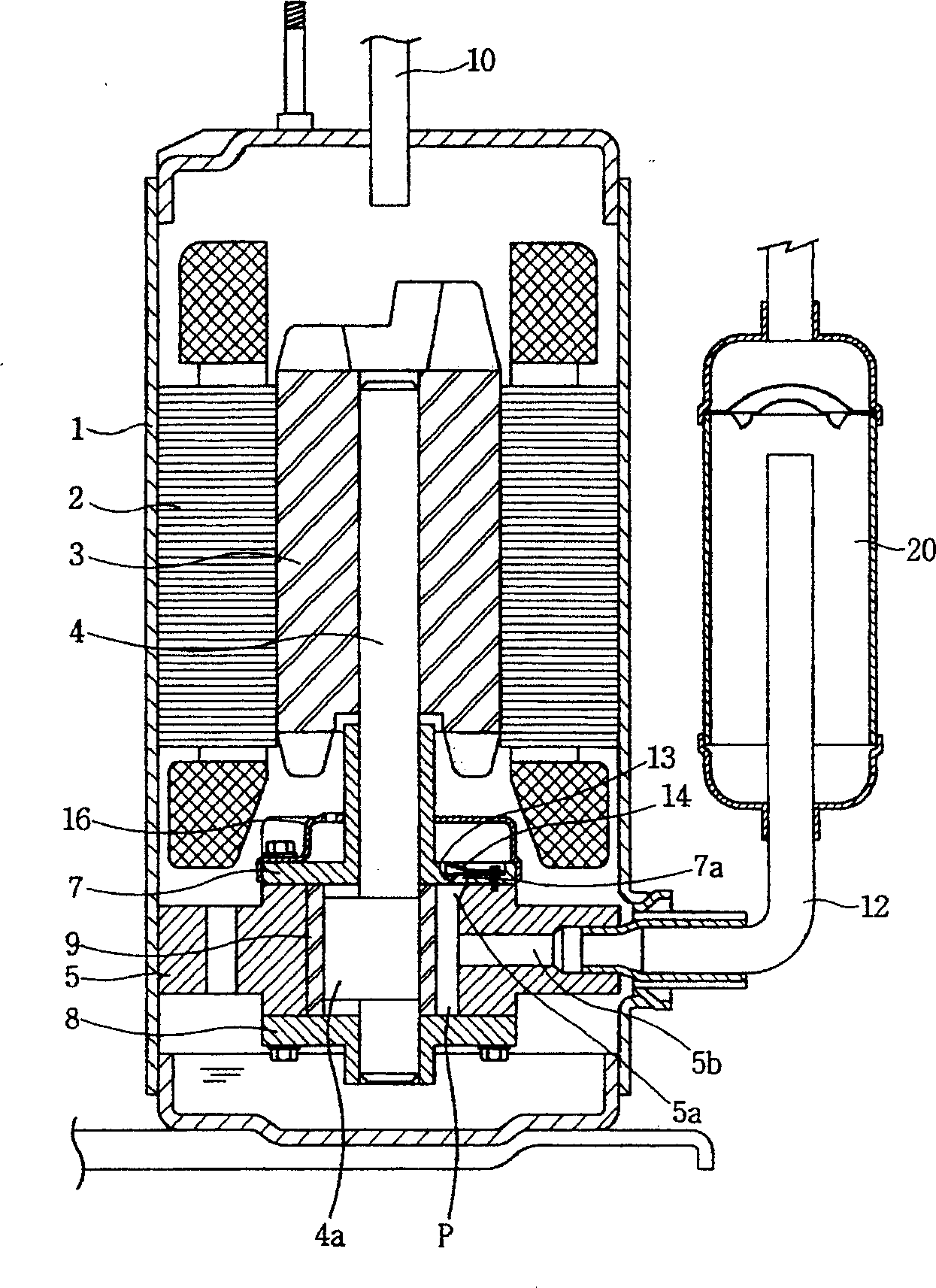

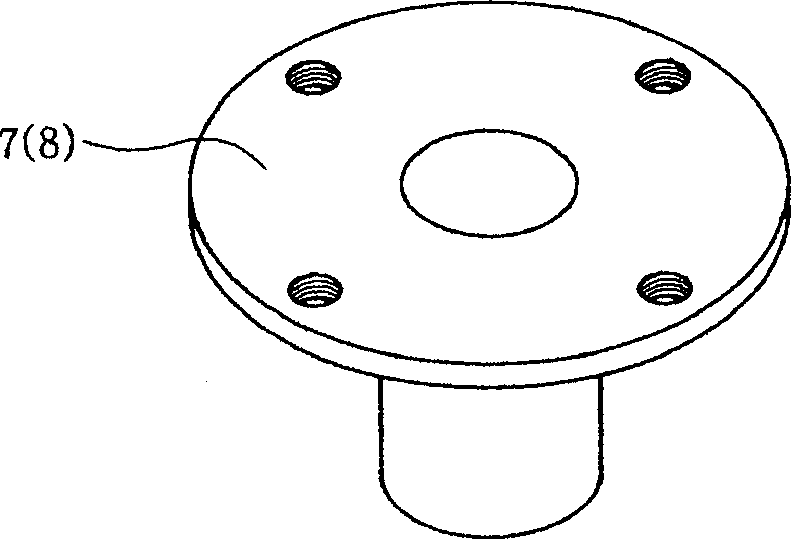

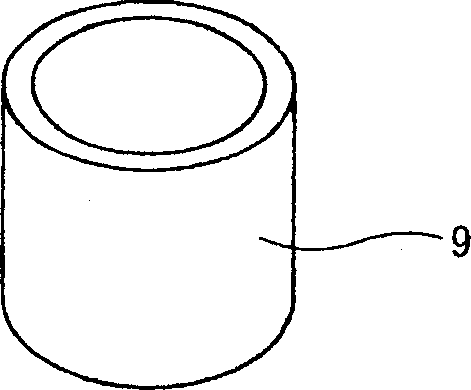

technical field [0001] The invention relates to a rotary compressor, in particular to a load-reducing structure of the rotary compressor. Background technique [0002] figure 1 is a sectional view of a conventional rotary compressor, figure 2 is an oblique view of a main or auxiliary bearing of conventional technology, image 3 An oblique view of a rolling piston of conventional technology. [0003] Refer to the above Figure 1 to Figure 3 It can be seen that a traditional compressor is composed of a casing 1, a motor provided inside the casing 1 to provide power, and a compression structure driven by the motor to compress refrigerant. The motor consists of a stator 2 and a rotor 3 fixed in a casing 1 . The compression structure is set in the casing 1, located at the lower part of the rotor 3, and consists of the rotating shaft 4, the eccentric shaft 4a below it, the gas compression chamber P, the cylinder 5, the main bearing 7, the auxiliary bearing 8 and the rolling ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C18/02

Inventor 郑仁修

Owner LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com