Processing device and processing system for flat-panel display glass

A technology of flat panel display and processing device, which is applied in the field of processing device and processing system for flat panel display glass, and can solve problems such as failure to obtain uniformity, difference in spraying time, uneven speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

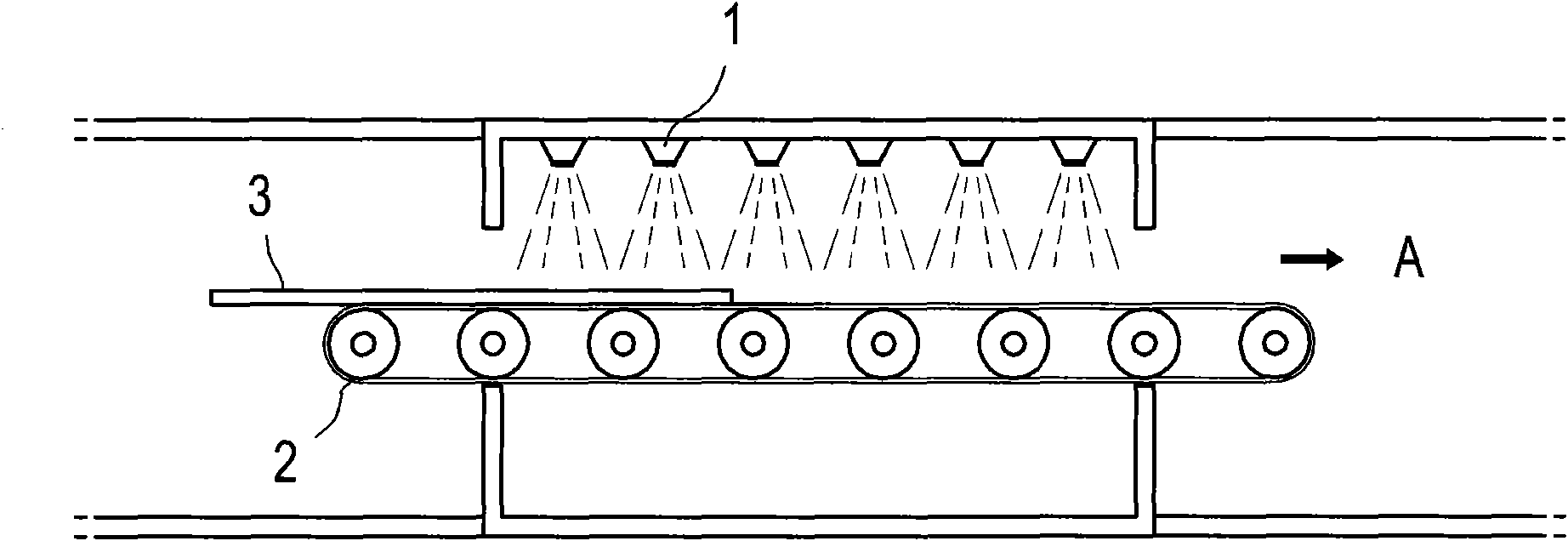

[0043] Figure 5 Several spray nozzles of the processing apparatus for flat panel display glass based on this invention are shown. Such as Figure 5 As shown, the jetting nozzles 10 of the processing apparatus for FPD glass based on the present invention are arranged without overlapping in the moving direction (direction A) of the flat panel display glass, more precisely, they are arranged in parallel without overlapping of the centers of the nozzles. A plurality of lines L1~L11.

[0044] as in Figure 5 As shown by the dotted line parallel to the A direction in , by arranging as described above, no area of the FPD glass will be repeatedly treated by the center P of the spray nozzle (longer than other areas) are processed evenly.

[0045] Seen along the moving direction of the FPD glass (direction A), this is the same as the case where all the spray nozzles are densely arranged in a row in the direction (direction B) perpendicular to the moving direction of the FPD glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com