Flexible printed circuit module

A flexible printing and circuit technology, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of multiple grounding pins, unable to provide, unable to provide grounding contact, etc., to achieve the effect of avoiding damage and strong electrostatic discharge ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

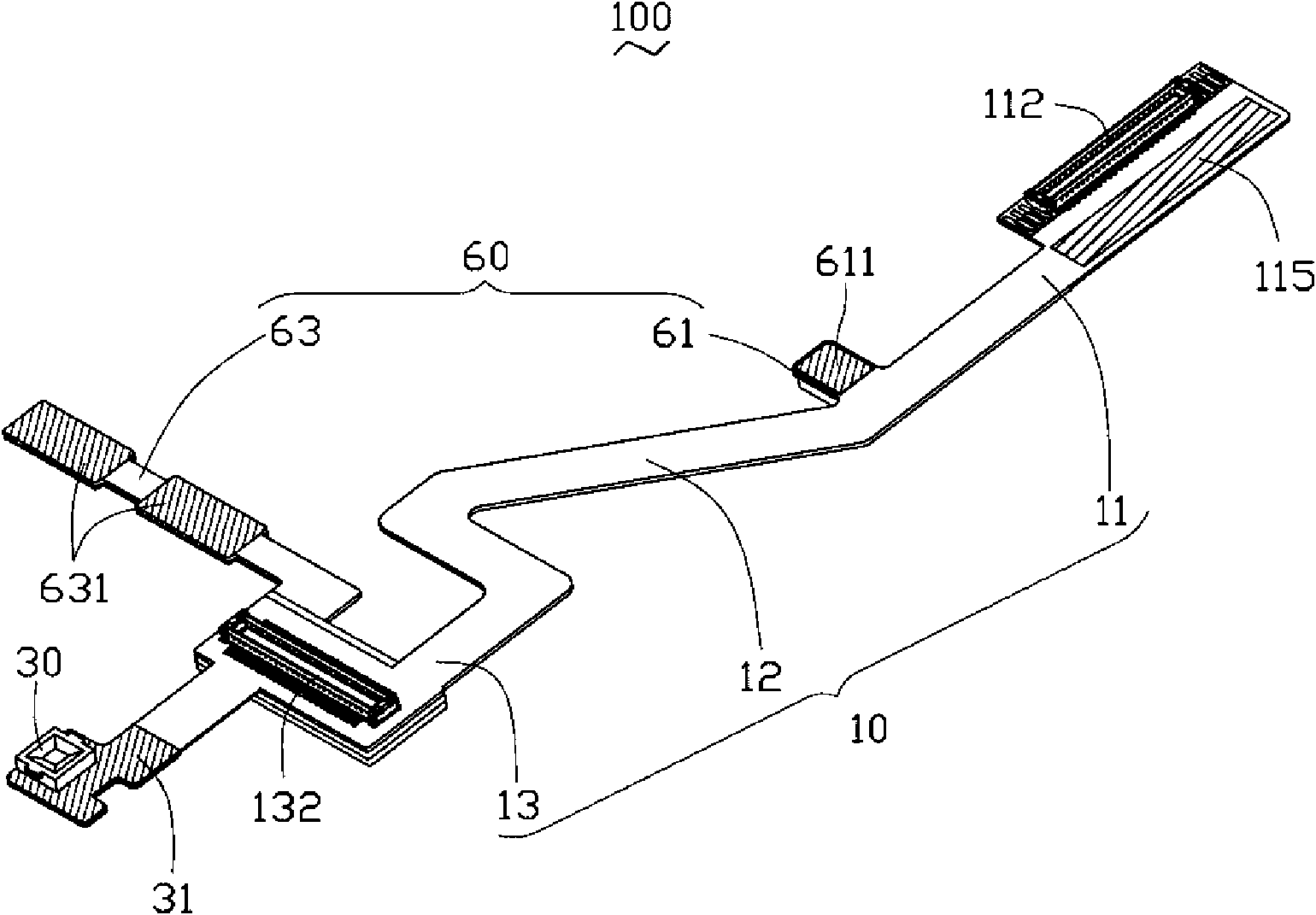

[0009] see figure 1 , the flexible printed circuit module 100 is in the shape of a bent strip, which includes a main body 10 , at least one connecting socket 30 and at least one grounding strap 60 . The main body 10 is a conventional flexible printed circuit board, which includes a first connection end 11 , a body portion 12 and a second connection end 13 . The first connecting end 11 and the second connecting end 13 are respectively located at opposite ends of the belt body 12, and the first connecting end 11 and the second connecting end 13 are respectively provided with a first connector 112 and a second connector 132 . A plurality of via holes (not shown) are opened through the strip body portion 12 , and several layers of circuits (not shown in the figure) are preset in the strip body portion 12 . Wherein, the several layers of circuits include grounding circuits, and the first connector 112 and the second connector 132 are electrically connected to each other through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com