In2Te3 phase-change memory element and preparation method thereof

A technology of phase change memory and components, which is applied to electrical components, ion implantation plating, coatings, etc., can solve the problems of inability to achieve fast reading and writing, difficulty in further improving recording density, etc., achieve excellent switching characteristics, improve component structure, The effect of significant difference in resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

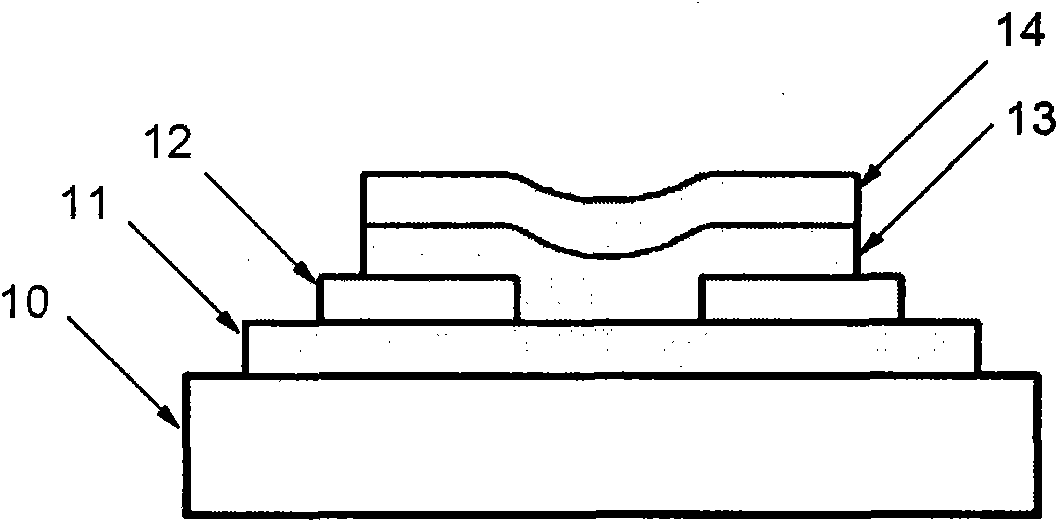

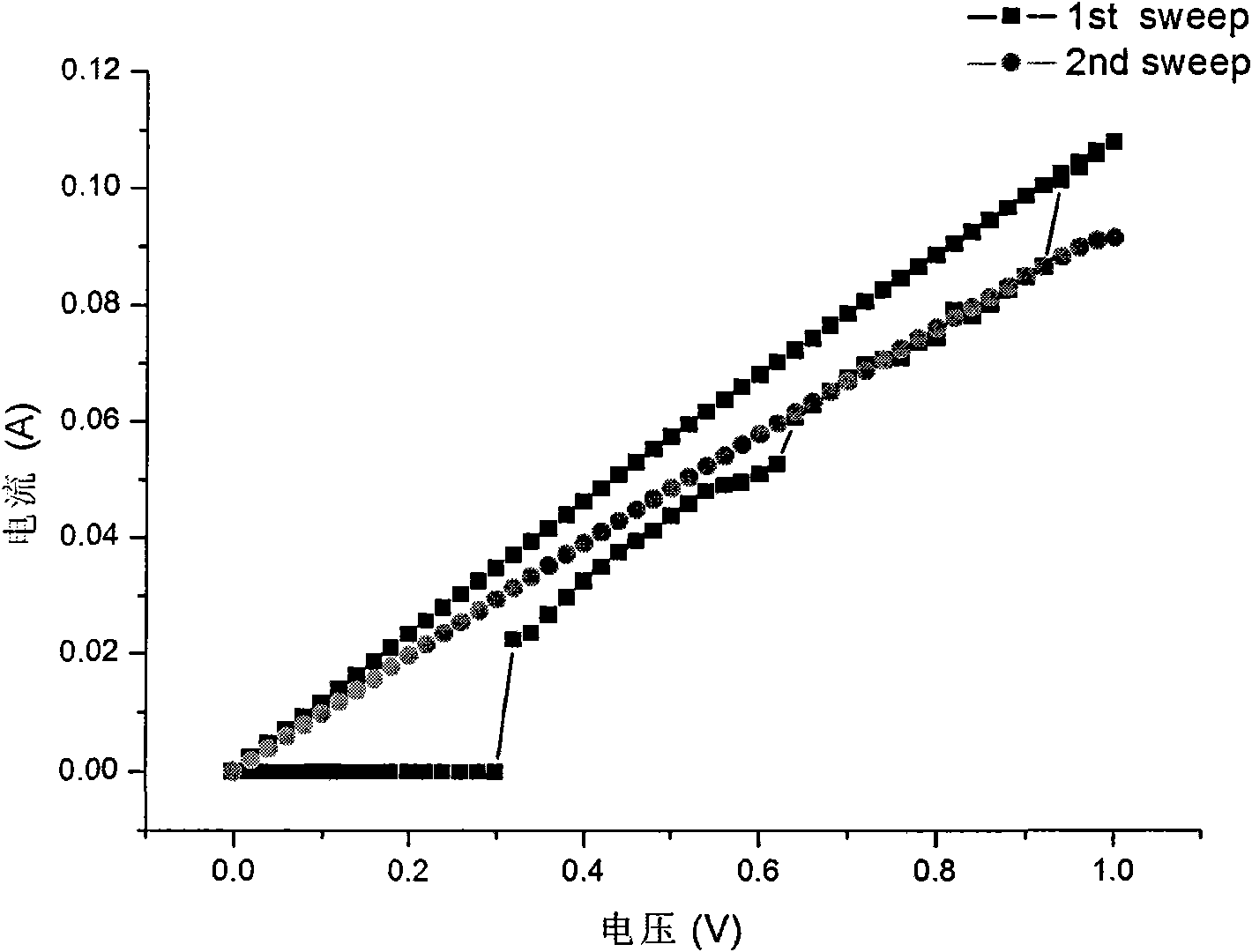

[0033] In the present invention 2 Te 3 Phase change memory element, using In 2 Te 3 The thin film is a phase-change memory storage material, and the In 2 Te 3 The film is amorphous at room temperature and becomes crystalline after annealing at 450-470°C.

[0034] In used in the present invention 2 Te 3 The thin film is prepared by pulsed laser deposition method in the pulsed laser deposition film-making system. Firstly, In 2 Te 3 target. In 2 Te 3 The target is made by vacuum suspension melting method: a mixture of In and Te with a molar ratio of 2:3 is melted at 650-750°C, melted into a block, and then the obtained block is cut and polished into a circular target .

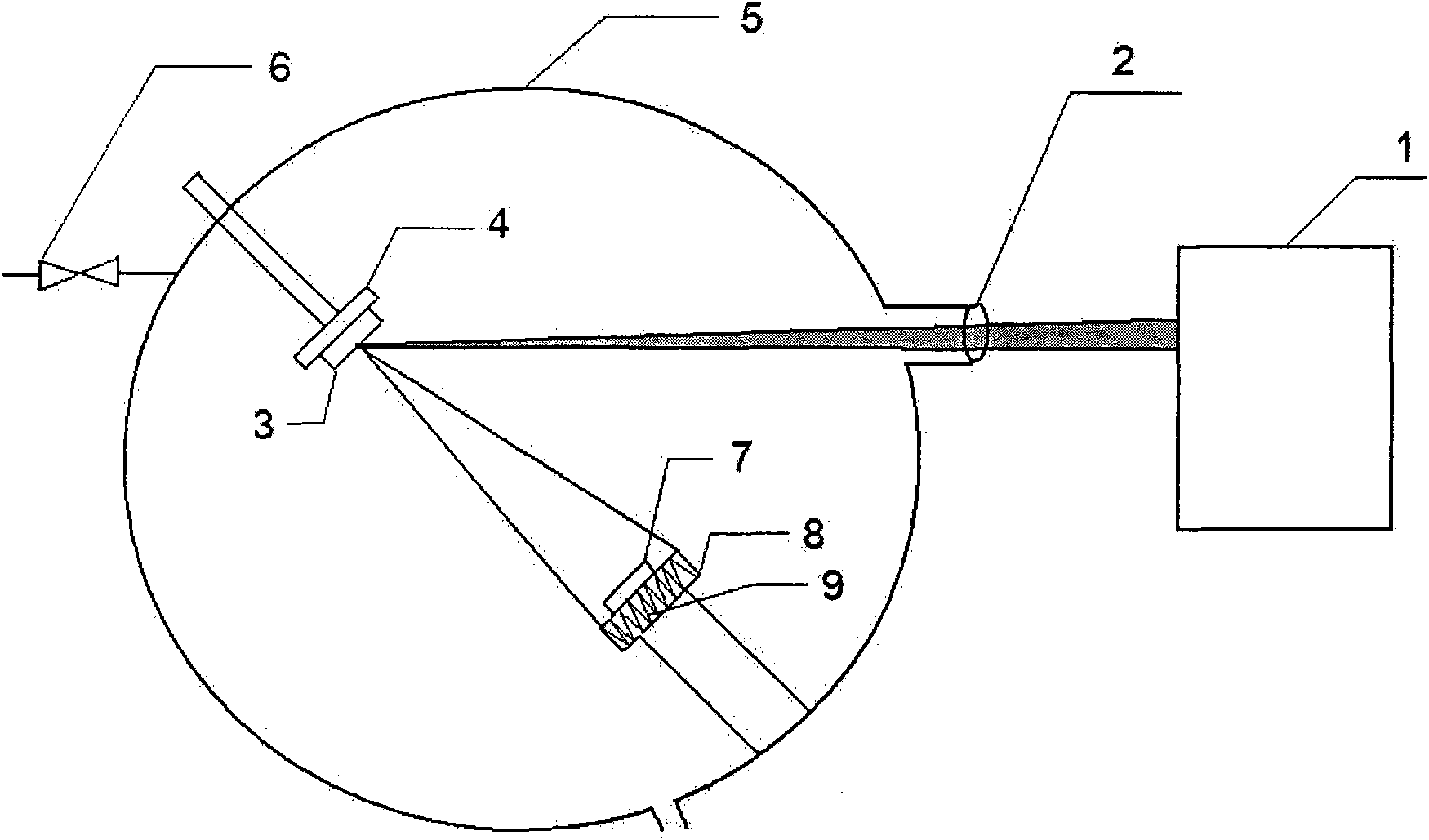

[0035] Afterwards, amorphous and crystalline In were prepared by pulsed laser deposition film forming system. 2 Te 3 film materials such as figure 2 :

[0036] a) put In 2 Te 3 The alloy target 3 is fixed on the target stage 4 of the pulsed laser deposition film-making system, the substrate 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com