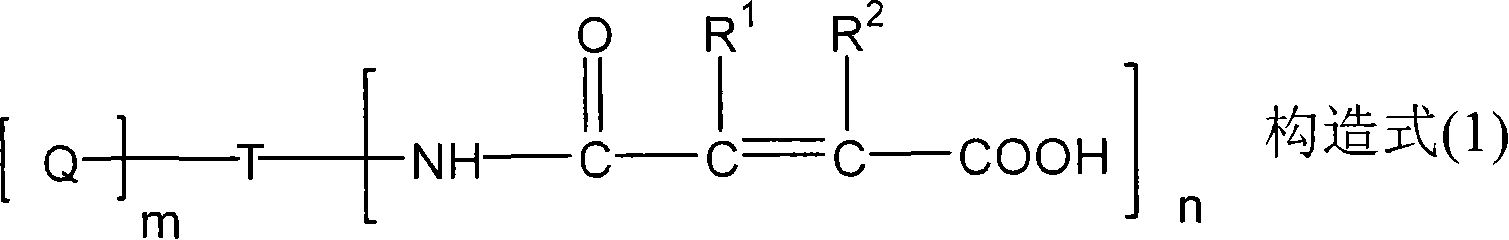

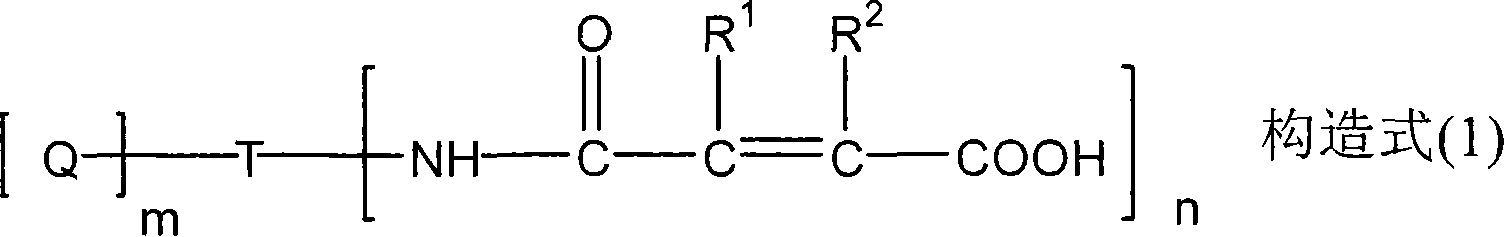

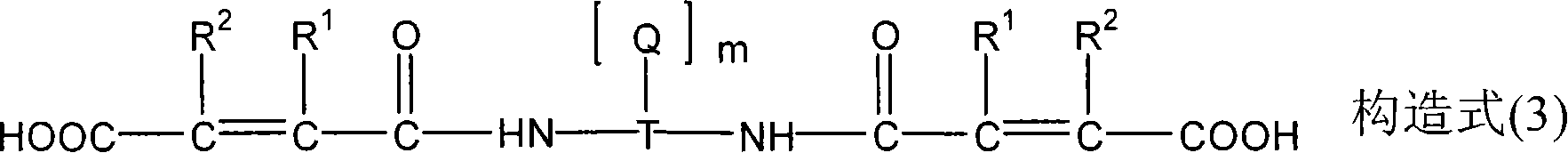

Liquid crystal oriented agent and method for manufacturing liquid crystal oriented film formed by same

A technology of liquid crystal orientation and orientation agent, which is applied in nonlinear optics, instruments, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0126]

Synthetic example 1

[0128] A nitrogen inlet, stirrer, heater, condenser and thermometer are arranged on a four-necked conical flask with a volume of 500 milliliters, and nitrogen is introduced and the feed composition is added in the amount shown in Table 1. The above feed composition includes: 1 - Octadecyloxy-2,4-diaminobenzene (hereinafter referred to as C18DA) 3.76g (0.01mole), and solvent tetrahydrofuran (hereinafter referred to as THF) 50g, stirred at room temperature until dissolved. Then add 2.45 g (0.025 mole) of maleic anhydride (hereinafter referred to as MAn) and react at room temperature for 3 hours. After the reaction, the reaction solution is filtered, and the filtered solid is repeatedly washed and filtered with THF three times, and placed in a vacuum After drying in an oven at a temperature of 60° C., the compound (A-1-1) containing two maleamic acid groups can be obtained.

Synthetic example 2~4

[0130] The operation method is the same as in Synthesis Example 1, except that the type of polyamine-based compound and the amount of maleic anhydride are changed. The detailed information is shown in Table 1.

[0131]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com