Thermocouple device used for measuring underground gasification temperature

A technology of temperature measurement and thermocouple, which is applied in the direction of measuring device, electric device, heat measurement, etc., can solve the problems of thermocouple damage, poor environmental adaptability, low work efficiency, etc., and meet the requirements of reducing the environment and saving the economy cost, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

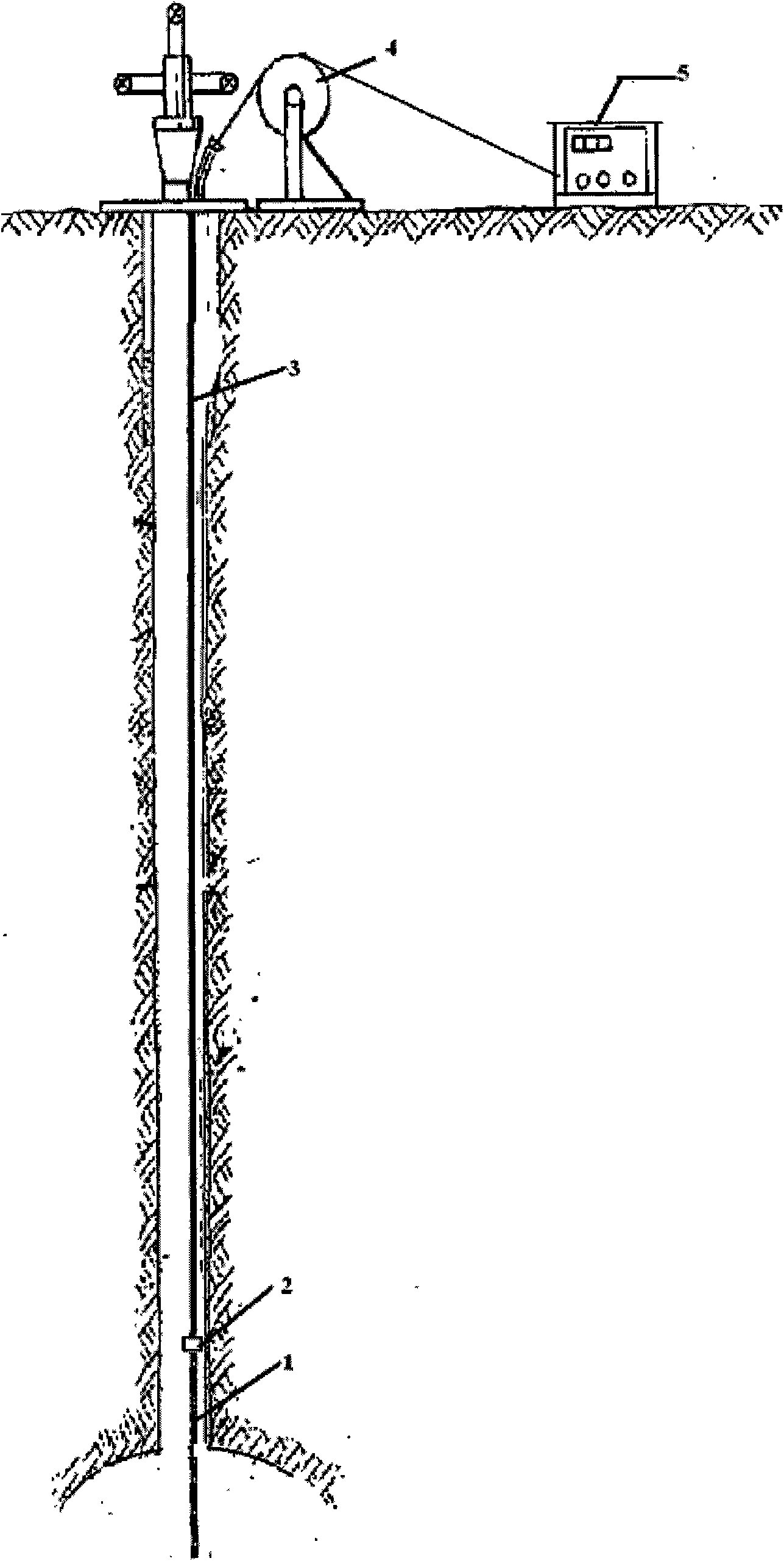

[0027] as attached figure 1 As shown, the thermocouple device used for underground coal gasification is composed of armored thermocouple (1), ceramic joint (2), compensation cable (3), electric cable car (4), and thermometer (5). The armored thermocouple (1) is controlled by the electric cable car (4) to go up and down the well, and the temperature data is read out by the thermometer (5). The measurement process has a high degree of automation and accurate temperature measurement.

[0028] as attached figure 2 As shown, the compensation cable (3) in the entire thermocouple device is connected to the armored thermocouple (1) through the ceramic joint (2), which is easy to disassemble and simplifies the manufacturing process of the thermocouple device.

[0029] as attached image 3 As shown, the electric cable car (4) is composed of an electric motor (7) that can be remotely controlled by a switch (6) and a winch (8). Downhole automation.

[0030] As shown in Figure 4, acco...

Embodiment 2

[0033] Adopt the thermocouple device that is used for underground coal gasification temperature measurement similar to embodiment 1, the difference is: connect with nickel base thermocouple wire (13) with thermocouple wire (9) and make armored thermocouple, this implementation For example, according to the depth of the well and the temperature gradient and length of the combustion zone, a 40m armored thermocouple is made by connecting a thermocouple wire (9) of about 5m with a nickel-based thermocouple wire (13), and the temperature of the nickel-based thermocouple wire is below 1000°C Can work for a long time, thermocouple structure such as Figure 4-b shown.

[0034] The depth of underground gasification wells is generally 300-2000m. The underground terrain and environment are complex, and thermocouples are prone to collision during the process of going up and down the well. Install a thermocouple and connect it to a cable with a length of about 300 to 2000m that is inlaid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com