Continuous heat seal device of packing list envelop

A technology of plastic bags and racks, which is applied in the field of plastic processing machinery, can solve the problems of bag hot stamping with different widths, high partial hot sealing temperatures, and uneven hot sealing strengths, and achieve firm hot sealing, low hot sealing temperature, The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

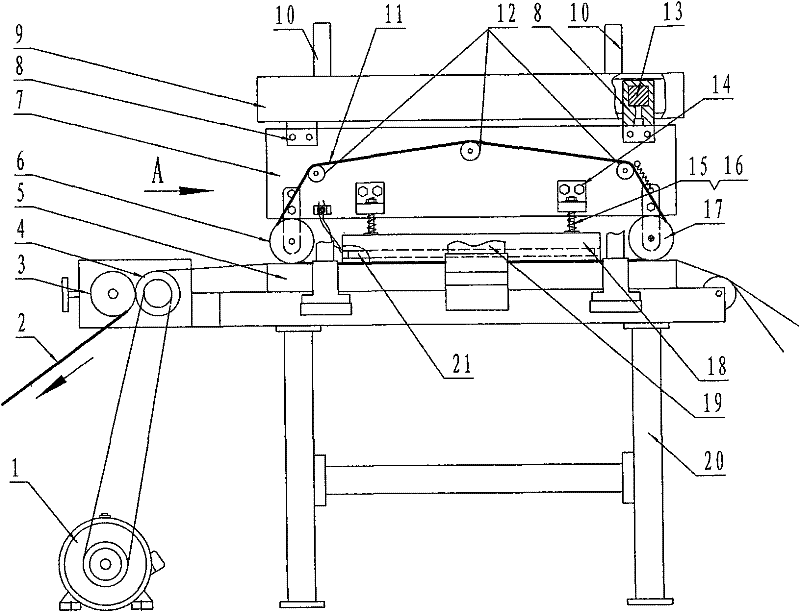

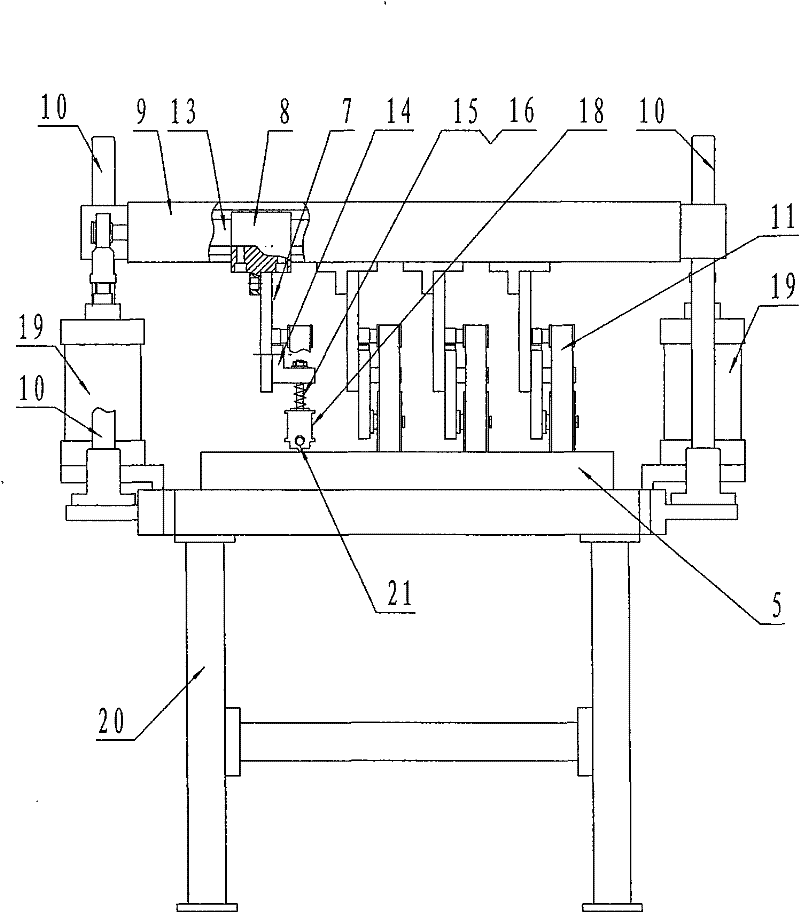

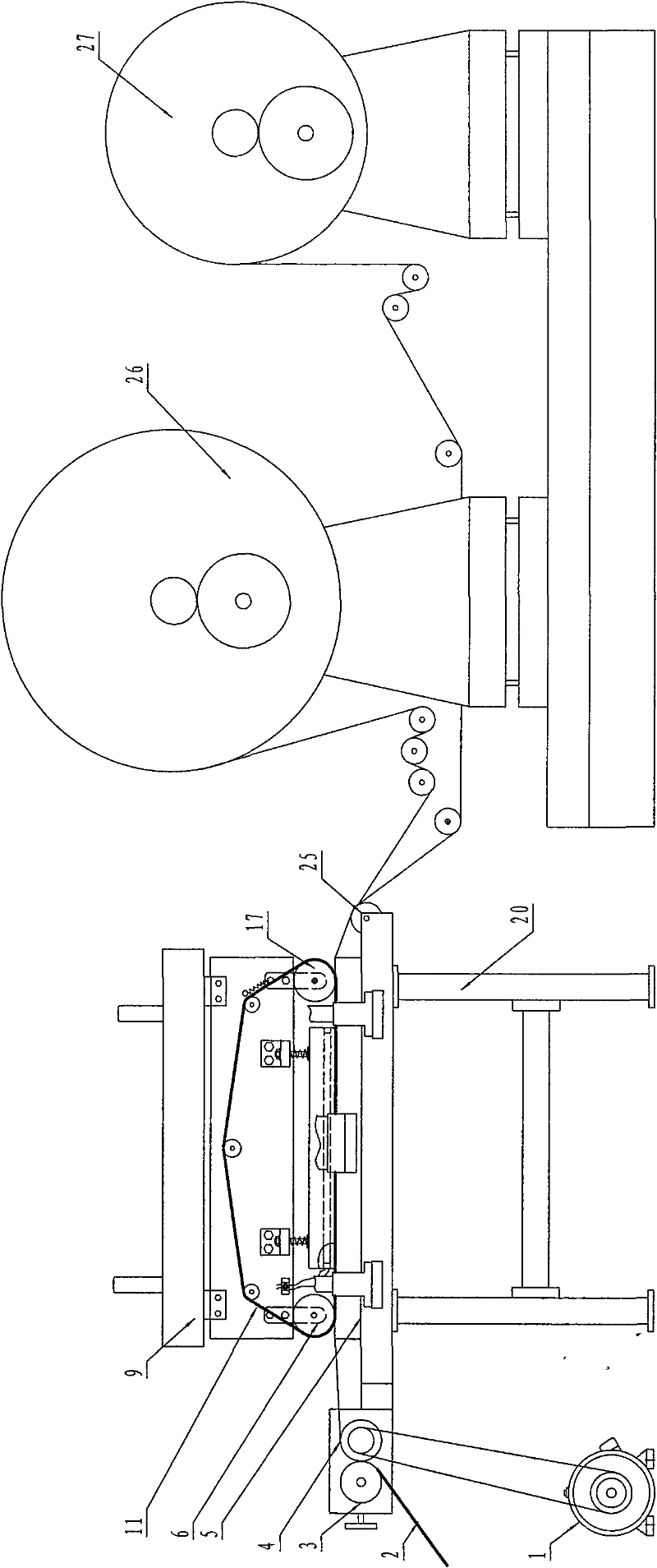

[0015] see figure 1 , the present invention is made up of frame 20, workbench 5, upper bracket 9, traction part, ironing part and ironing knife pressing and lifting mechanism, and workbench is positioned on the frame, and upper bracket is supported by ironing knife pressing and lifting mechanism. The raw material of adhesive bag film is input from the right side of the workbench, and after being longitudinally ironed by the ironing part, it is output from the left side of the workbench. The ironing part comprises a vertical ironing knife 18, an ironing knife fixing plate 7, an ironing belt 11, a front pulley 17, a rear pulley 6 and a supporting pulley 12, the ironing knife fixing plate is connected to the upper bracket, and the vertical ironing knife is in the form of strips. Shape, a heating rod 21 is arranged in the vertical scalding knife, and the temperature of the vertical scalding knife is measured and controlled by a thermocouple and a thermometer, and the control accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com