Wrapping machine for single or grouped and/or stacked products, in packs of thermoplastic material obtained from film unwound from a reel and related operating method

A thermoplastic material and product packaging technology, which is applied in multiple packages, transportation and packaging, paper product packaging, etc., can solve problems such as limiting productivity and limiting the operating speed of packaging machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

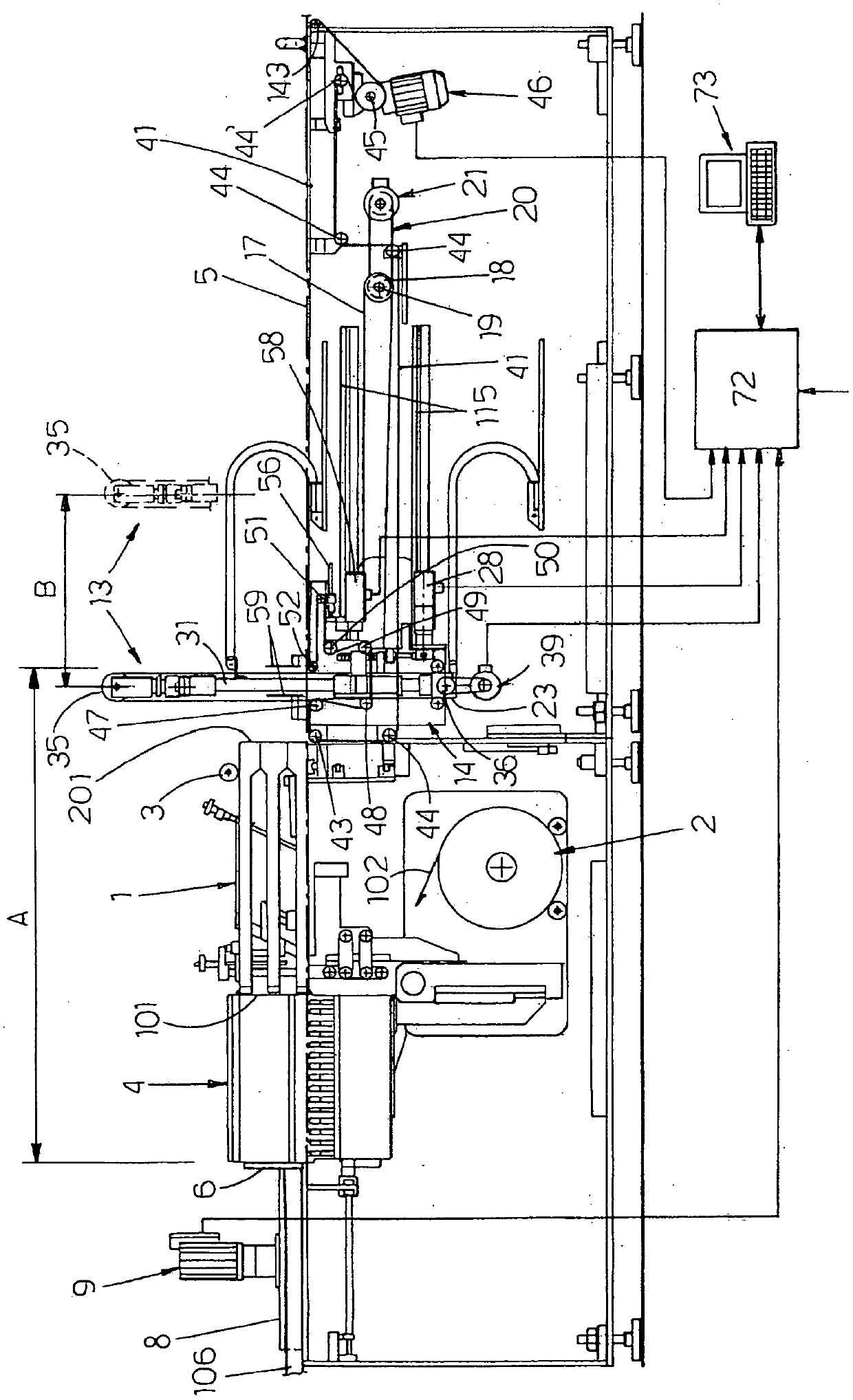

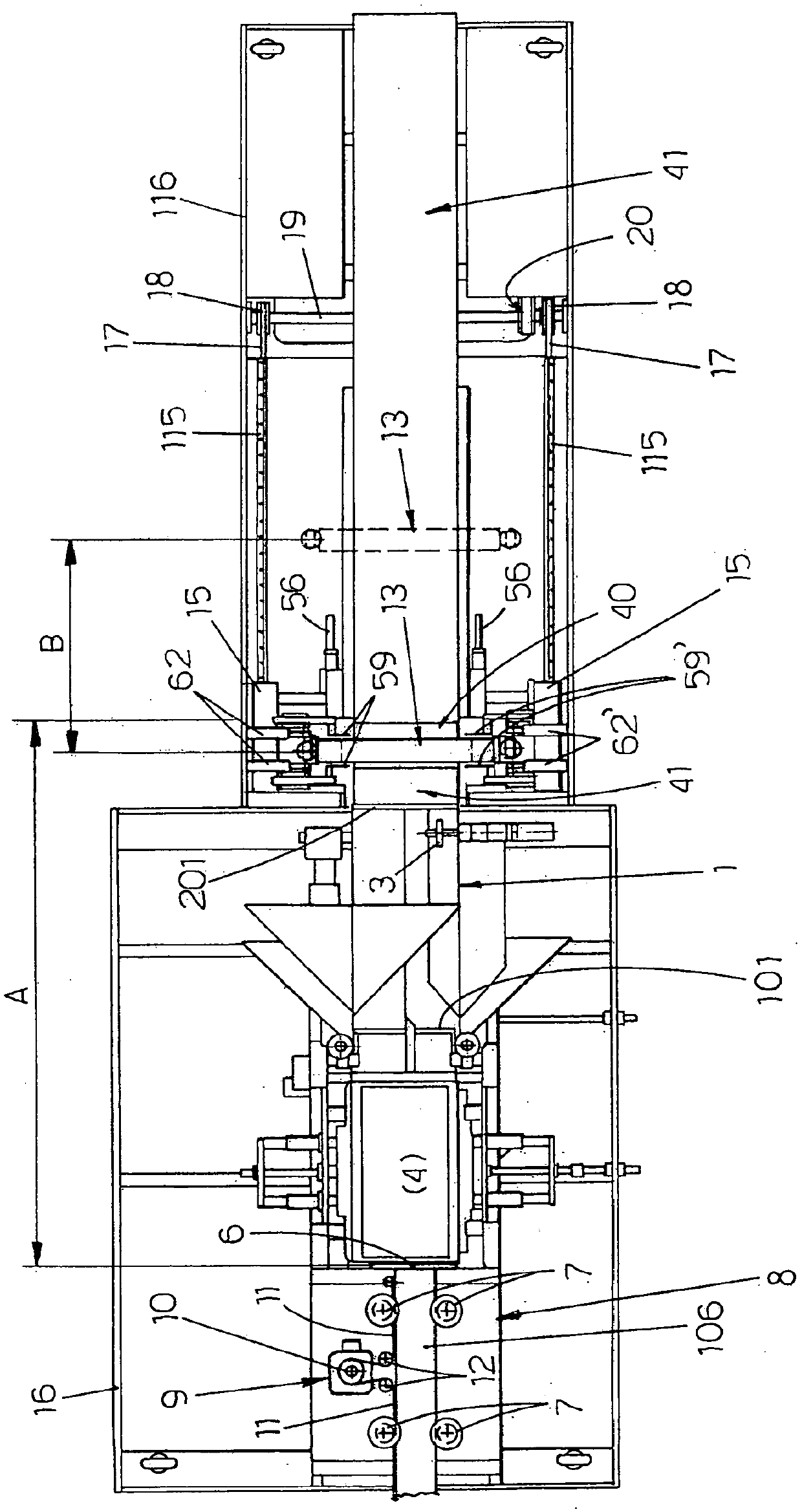

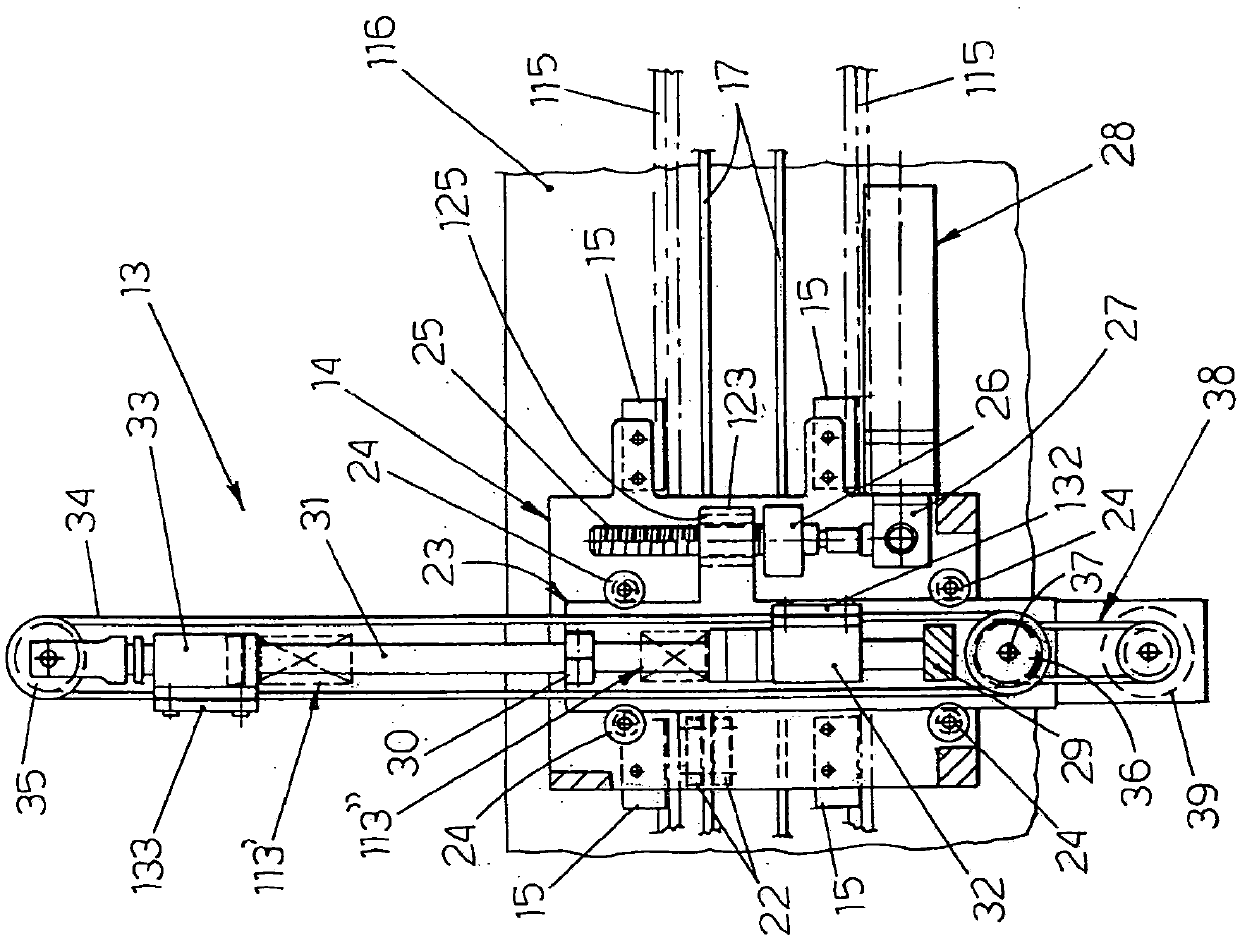

[0022] from figure 1 with figure 2 It can be seen how the packaging machine comprises, as an intermediate part, an axially hollow mandrel 1 in the shape of a sailor's tie with a rectangular or square cross-section, capable of being carried out when the form of the package to be produced is changed. Adjustment, the longitudinal axis of the axial hollow shaft is positioned horizontally, the axial hollow shaft is provided with an open end 101 on the left side when viewing the figure, through which the film 102 from the reel 2 below enters , and made to adopt a tubular shape by means of the guide of a mandrel, generally in the shape of a sailor's tie, moving longitudinally along said mandrel 1 towards its outlet 201, wherein the longitudinal slices of said film overlap each other and are heat-sealed by means of a known type of heat sealing The device 3 heat-seals them successively to each other, so that the above-mentioned film exits from the outlet 201 of the mandrel 1 in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com