Thermoplastic resin physical foaming material preparation device and preparation method thereof

A technology for thermoplastic resin and preparation equipment, which is applied in the field of thermoplastic resin foaming materials, can solve the problems of limited application range and increased energy waste, and achieve the effects of simple process flow, no waste of raw materials, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

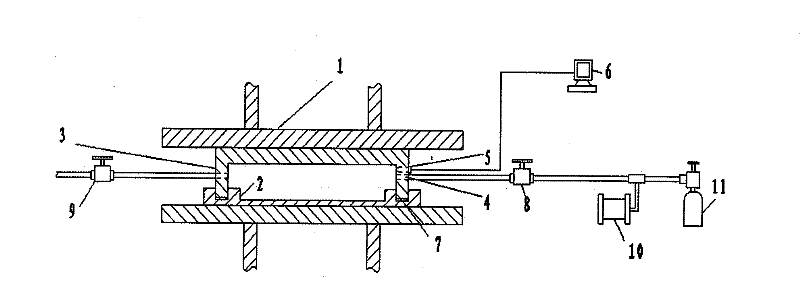

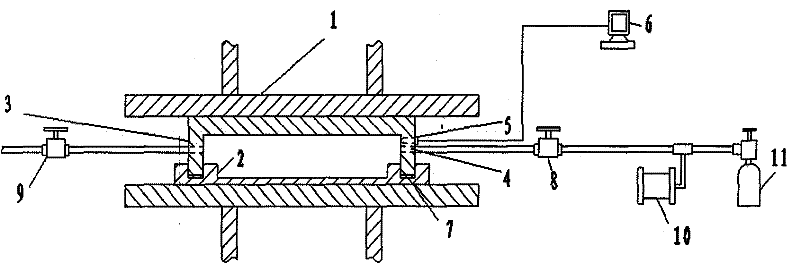

[0039] Such as figure 1 As shown, the preparation device of thermoplastic resin physical gas foaming material is composed of a hot press 1 , a high-pressure container 2 and a gas pressurization system 10 . The high-pressure container 2 is placed between the upper and lower platens of the heat press. One end of the high-pressure container 2 is provided with a gas inlet 4, and the gas inlet is connected with the gas pressurization system 10 and the gas storage tank 11 through the gas control valve 8, and the other end of the high-pressure container is provided with a gas outlet 3, and the gas outlet It is connected with the pressure relief control valve 9, and the high-pressure container is also provided with a temperature and pressure sensor 5, which is connected with the data receiving and processing system 6. The high-pressure container is a combination of upper and lower templates, and a sealing ring 7 is arranged between the templates.

[0040]The preparation method of th...

Embodiment 2

[0041] Embodiment 2, the preparation of high-density polyethylene and polypropylene blend foam material

[0042] According to the preparation device of Example 1, the high-density polyethylene and polypropylene blend foam material was prepared. The blends of high-density polyethylene and polypropylene (20 / 80) were prepared by MiniLab micro-blending rheometer of HAAKE company. The preparation conditions are: melting temperature 190° C., conical twin-screw mixing at 50 rpm for 5 minutes. The mixed extrudate was sheared into particles 4 mm long, 4 mm wide, and 1 mm thick.

[0043] The blend particles are placed in the mold, ensuring that the total volume of the particles does not exceed 1 / 25 of the volume of the mold, so that the particles have enough space for foaming. Then the mold is put between the pressing plates of the hot press, and the hot press closes the mold, and the pressure acting on the mold is 30MPa. Heat the mold to 167°C with a hot press, inject nitrogen into ...

Embodiment 3

[0044] Embodiment 3, the preparation of low-density polyethylene foam material

[0045] According to the preparation device of Example 1, the low-density polyethylene foam material was prepared. The low-density polyethylene particles are placed in the mold, ensuring that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. Then the mold is put between the pressing plates of the hot press, and the hot press closes the mold, and the pressure acting on the mold is 20MPa. Raise the temperature of the mold to 110°C through a hot press, inject nitrogen into the mold from a booster pump at a pressure of 5 MPa, keep the temperature and pressure constant for 60 minutes, and then release the pressure in the mold at a speed of 5 MPa / s to Atmospheric pressure. Unload the pressure of the hot press, take out the mold and open it, take out the expanded low-density polyethylene particles, and cool them at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com