Sliding plate for off-line baking continuous casting ladle and molten steel outlet replacing method

A replacement method and continuous casting steel technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as waste, and achieve the effect of improving the safety and reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

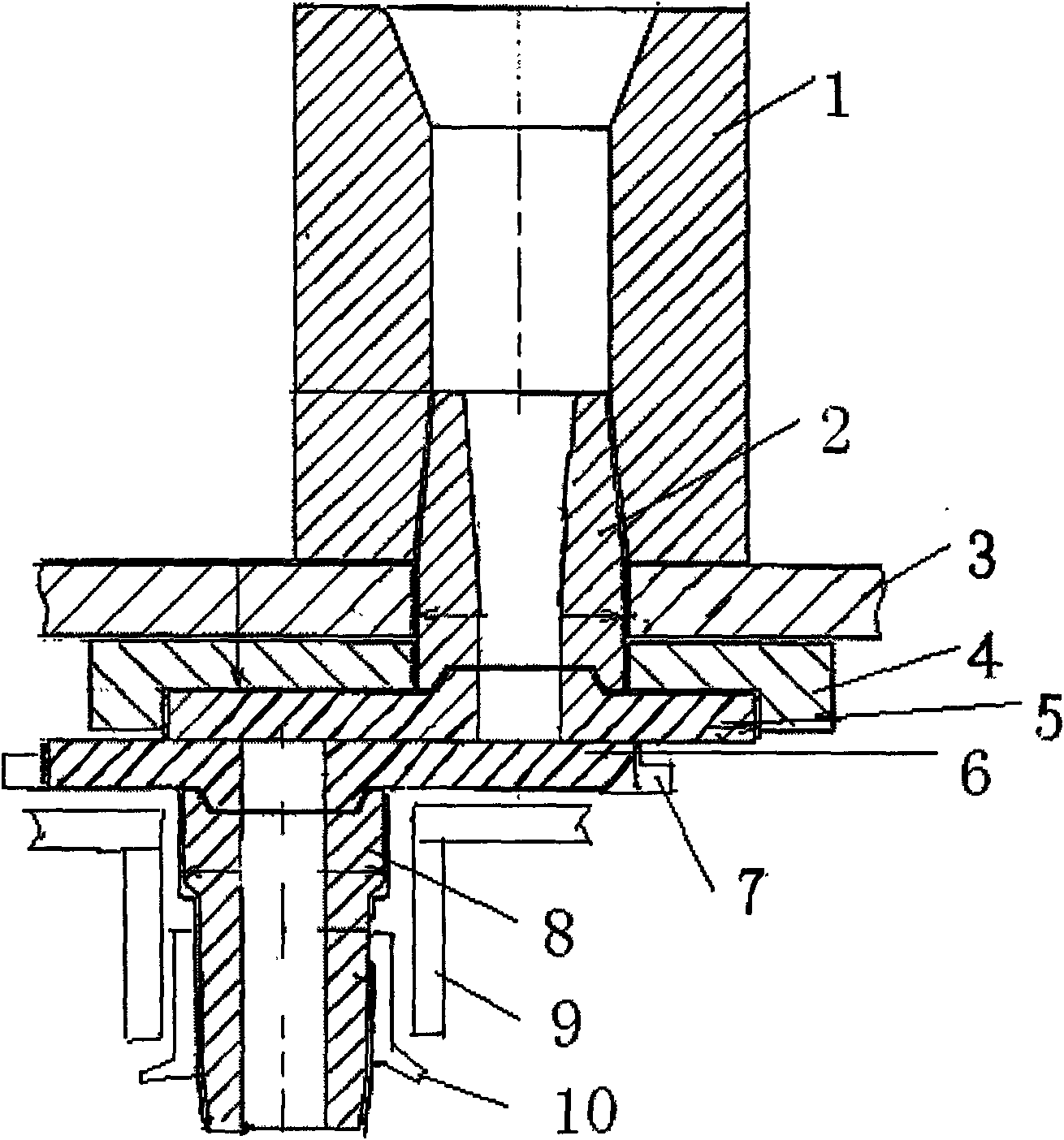

[0020] A method for replacing a sliding plate and a drain of an off-line baking continuous casting ladle, such as figure 1 As shown, the steps are as follows:

[0021] 1) Oxygen blowing and cleaning of the nozzle hole: start the electric switch of the oil cylinder to make the slide plate fully open (align the hole of the lower slide plate with the hole of the upper slide plate) 1. The residual steel attached to the hole of the upper slide plate (5), the hole of the upper nozzle (2) and the hole of the block (1) of the upper nozzle are blown clean;

[0022] 2) After cleaning the nozzle hole by blowing oxygen, do not remove the old upper slide (5), lower slide (6) and water outlet (8), lift the ladle from the packing preparation position to the off-line baking position by driving, and carry out baked, ready to use;

[0023] 3) Before the steel ladle for offline baking is planned to be put into use, the steel ladle is hoisted from the offline baking position to the packing prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com