Programming control method applied to boiler pulverizing system of coal-fired generating unit and device

A technology of generator set and milling system, which is applied in the program control, electrical program control, grain processing and other directions in the sequence/logic controller, which can solve the problems affecting the stability of the milling system, the complexity of manual operation, and the impact on economic benefits, etc. problems, to achieve the effect of optimizing forecast processing, reducing costs, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

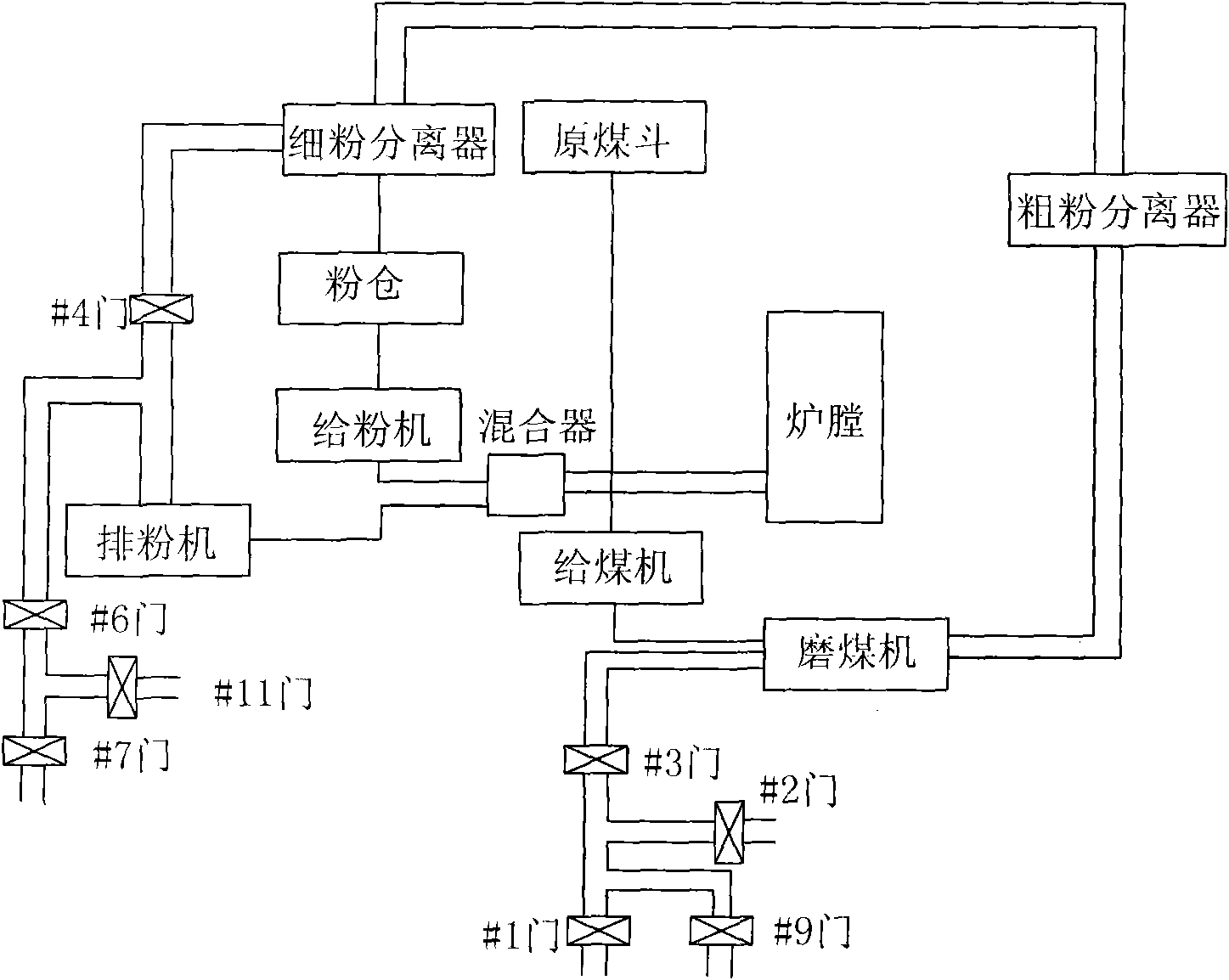

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

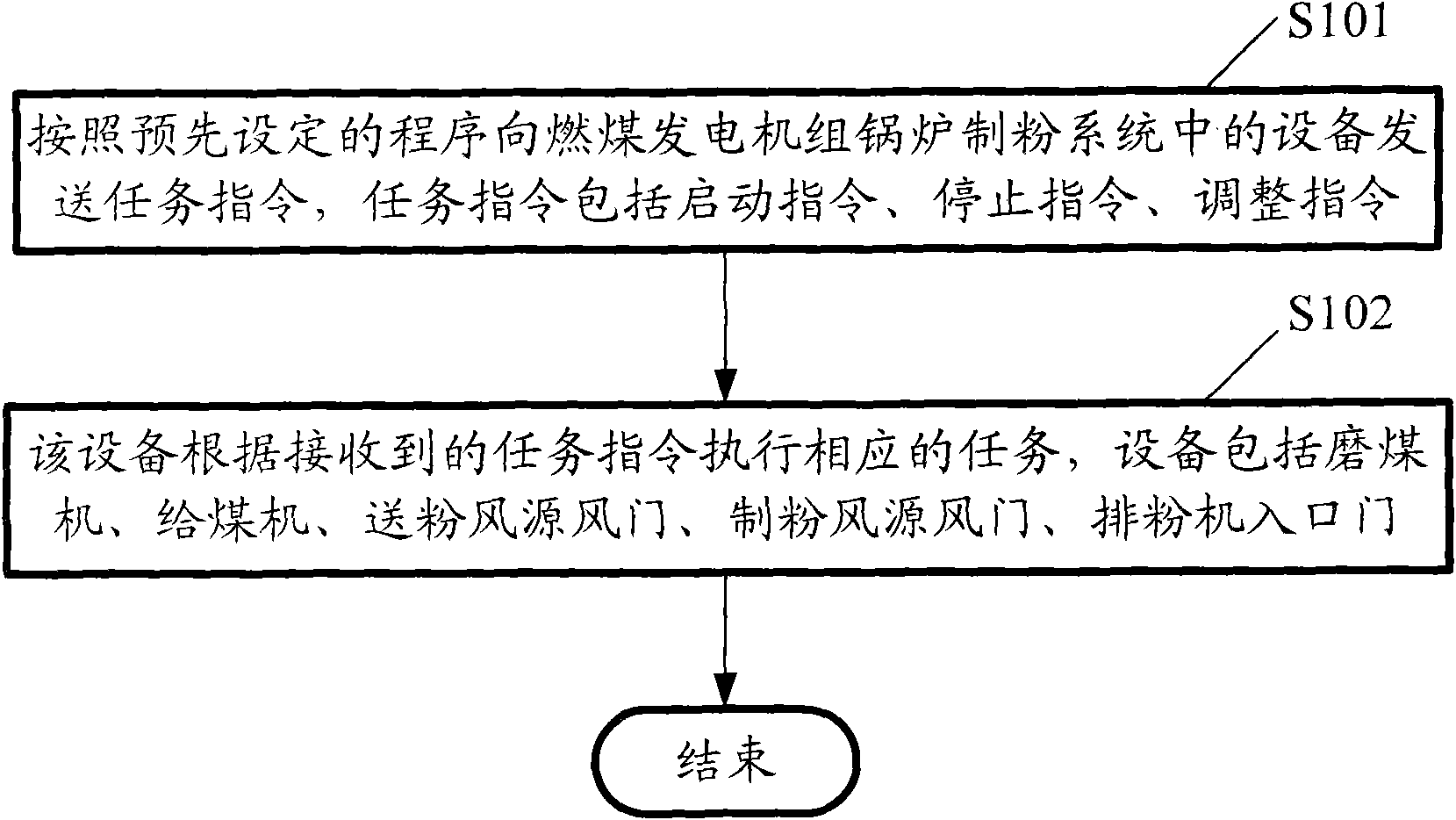

[0025] In order to realize the automatic control of the boiler pulverization system, the embodiment of the present invention provides a program control method applied to the boiler pulverization system of coal-fired power generation units, see figure 2 shown, including the following steps:

[0026] S101: Send task instructions to the equipment in the boiler pulverization system of the coal-fired generating set according to the preset procedure; machine entrance door, the task instructions include start instructions, stop instructions, adjustment instructions;

[0027] S102: The device executes a corresponding task according to the received task instruction.

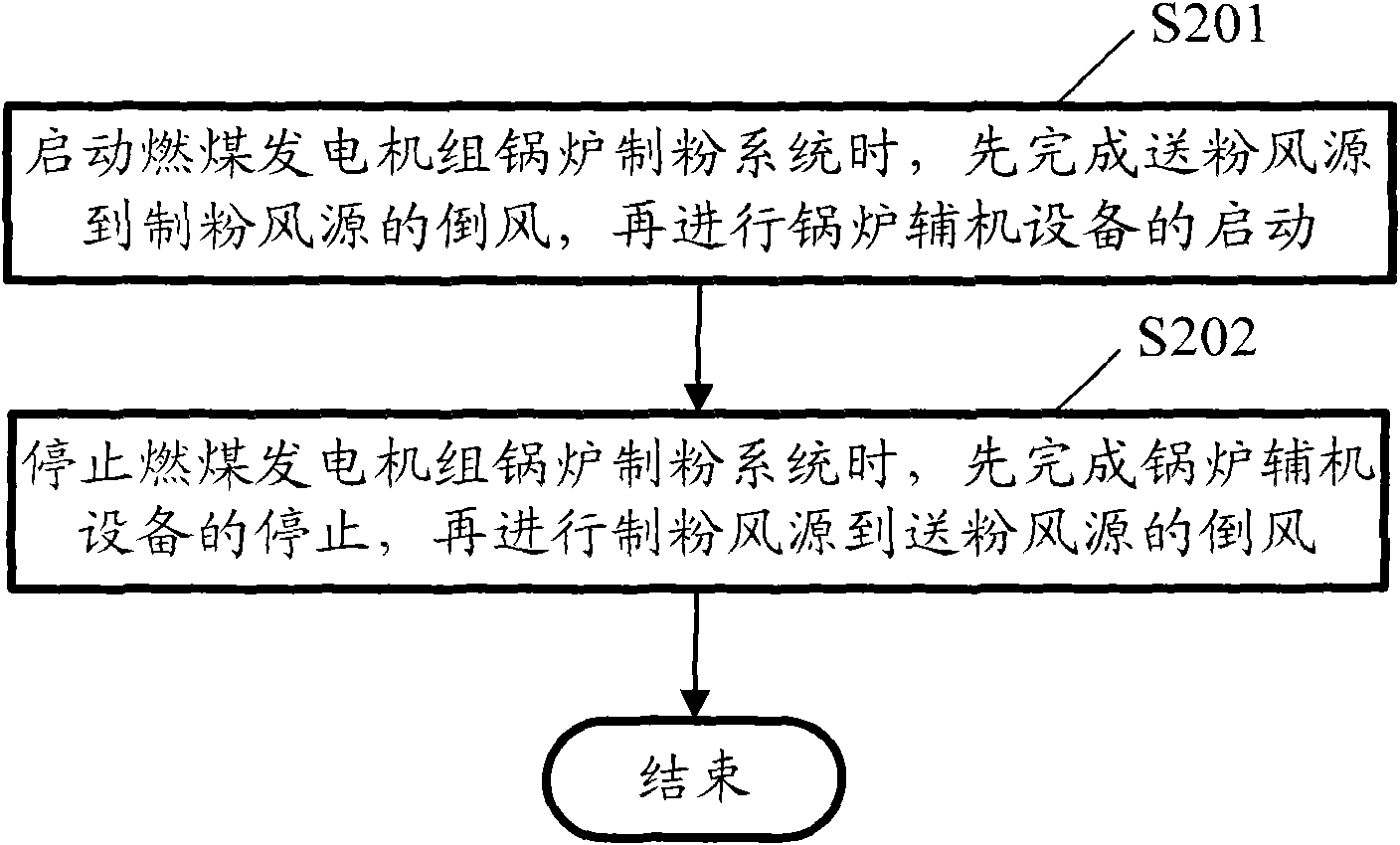

[0028] see image 3 As shown, the preset program described in step S101 includes the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com