Reformer system, fuel cell system, and their operation method

A fuel cell system and fuel cell technology, which can be used in fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

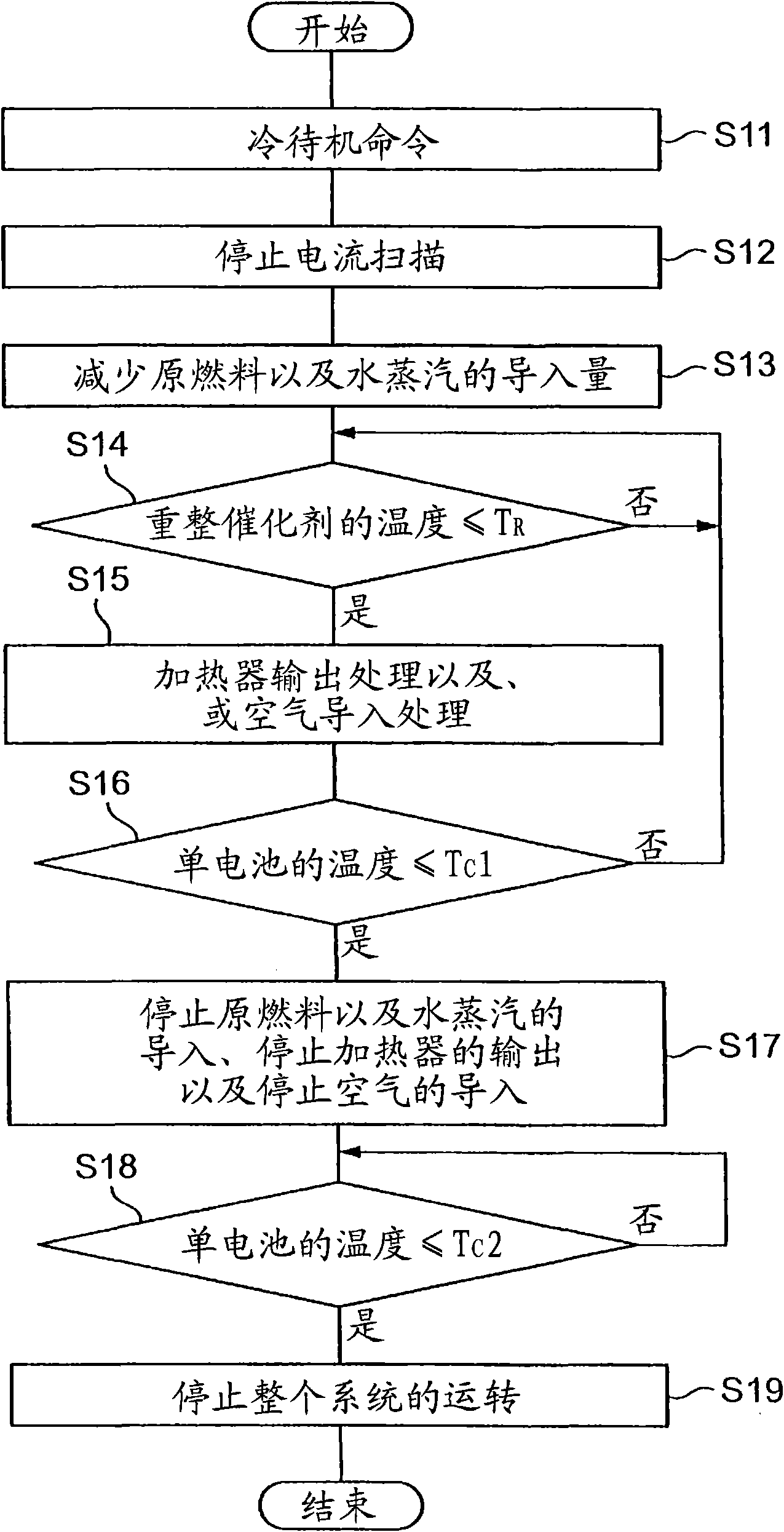

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

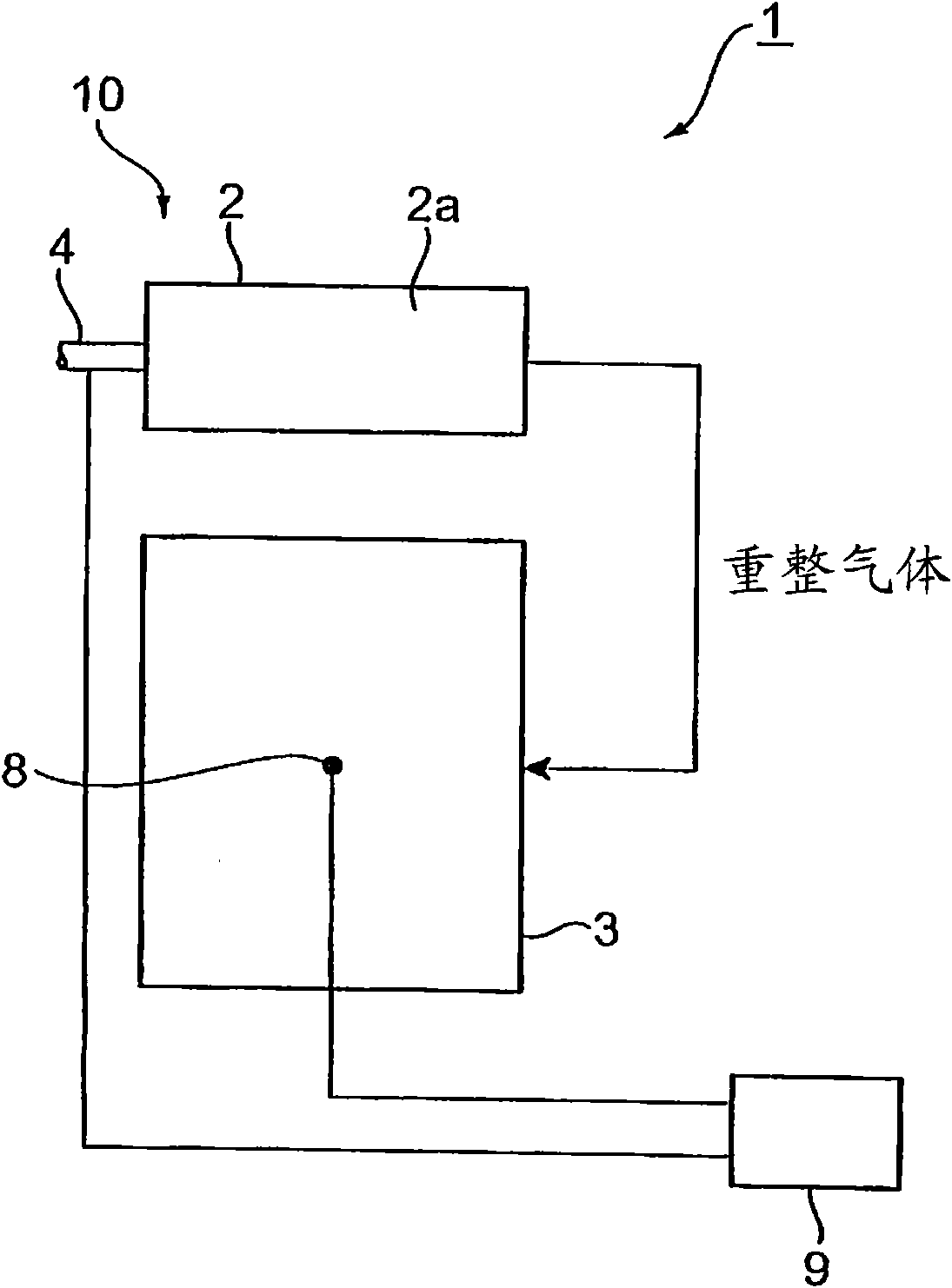

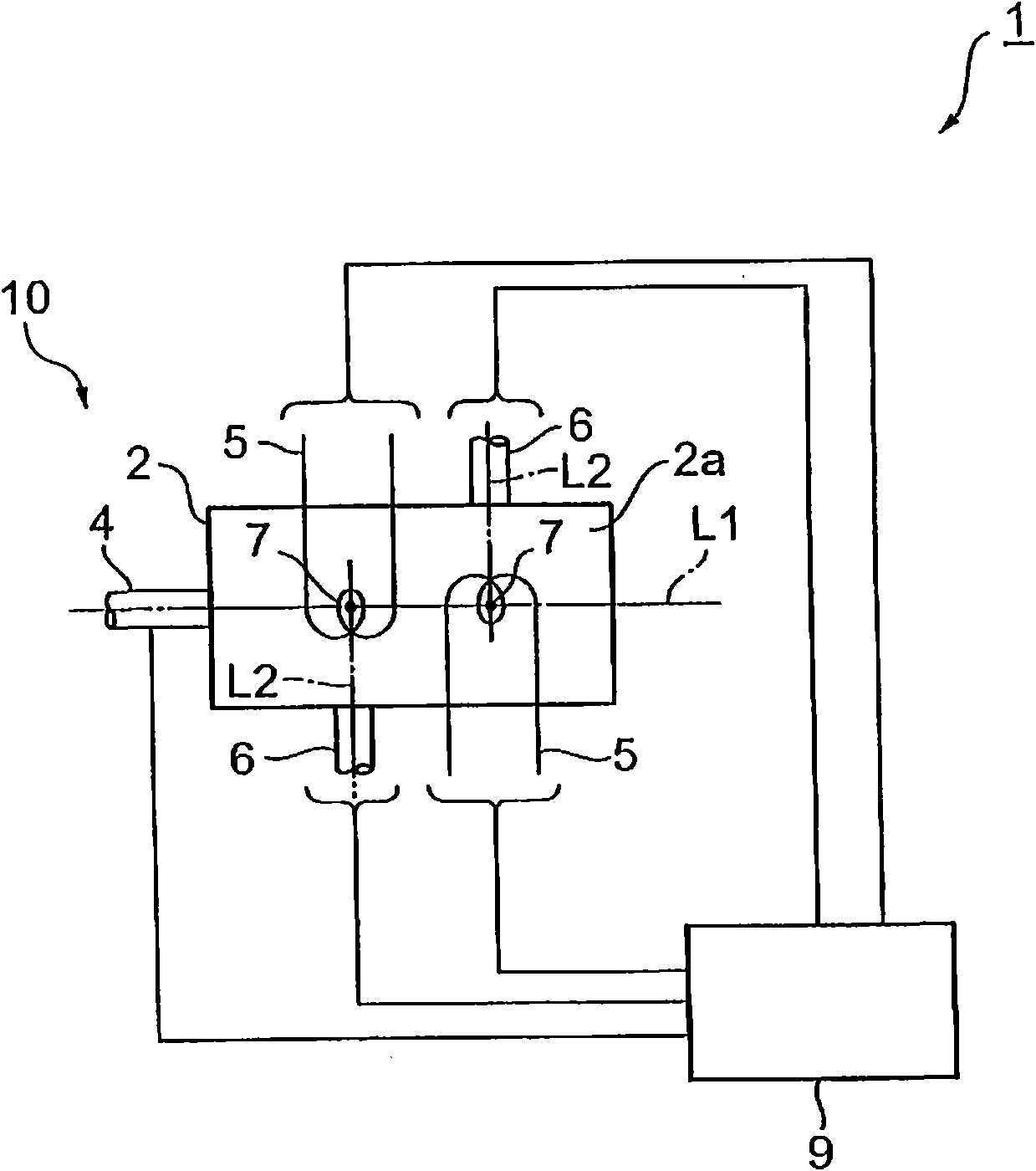

[0034] Such as figure 1 and figure 2 As shown, a fuel cell system 1 includes a reformer 2 that generates a reformed gas by reforming a raw fuel with a reforming catalyst 2a, and a solid oxide fuel cell 3 that uses the reformed gas as fuel.

[0035] The reformer 2 uses the reforming catalyst 2a to cause a steam reforming reaction between raw fuel and water vapor (water) to generate a hydrogen-containing reformed gas. Since the steam reforming reaction is an endothermic reaction, the reformer 2 utilizes the exhaust heat of the fuel cell 3 for the steam reforming reaction. As the reforming catalyst 2a, a catalyst known as a steam reforming catalyst can be used. That is, examples of steam reforming catalysts include ruthenium-based catalysts and nickel-based catalysts.

[0036] As the raw fuel, the raw material of the reformed gas can be a hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com