Production process of novel high-precision ultra-thin key

A production process, high-precision technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of grinding the surface of the press, blurring graphic characters, etc., to reduce post-processing links, facilitate production and configuration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

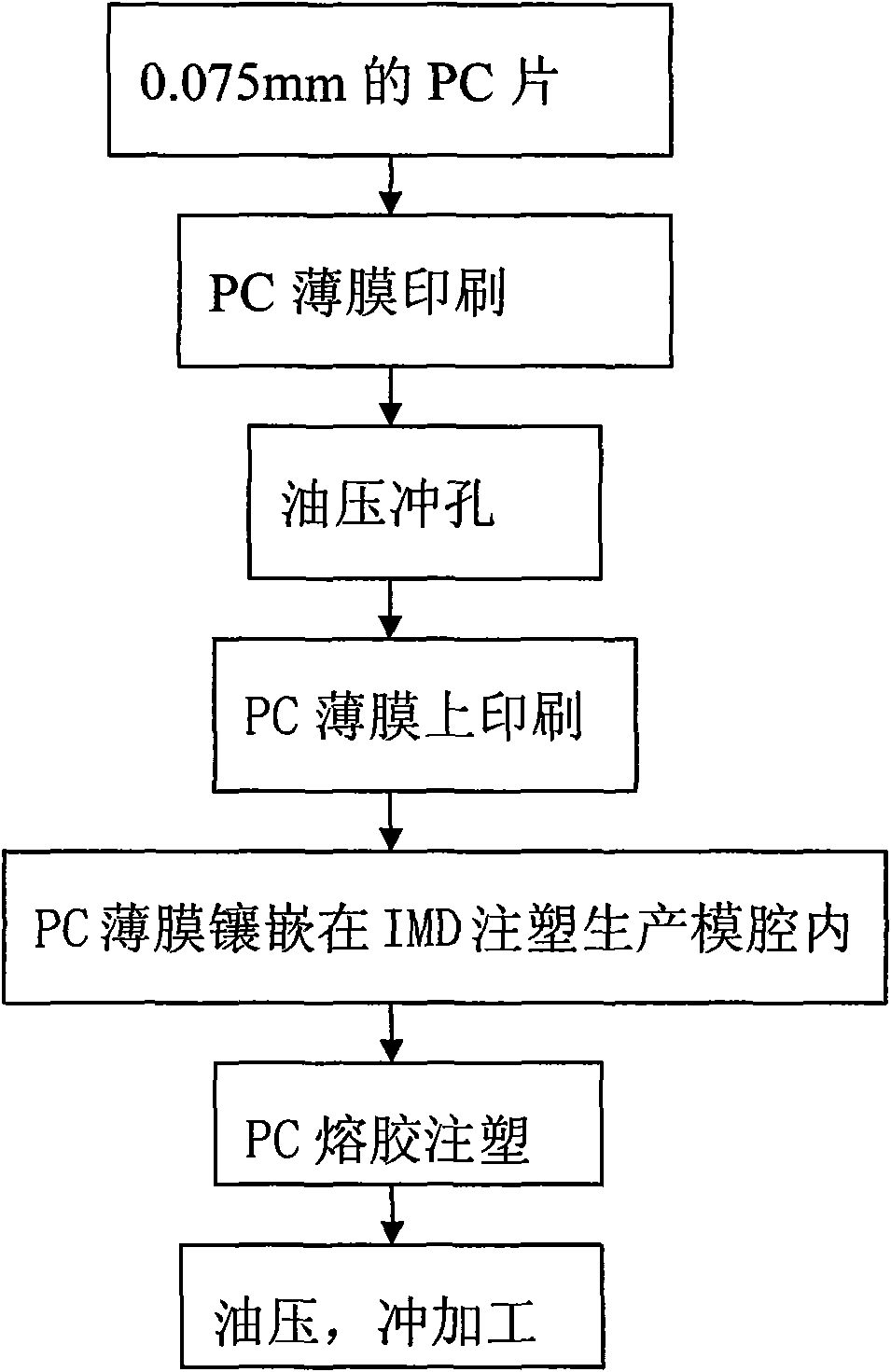

[0026] see figure 1 , a production process of high-precision ultra-thin keys, which includes the following steps:

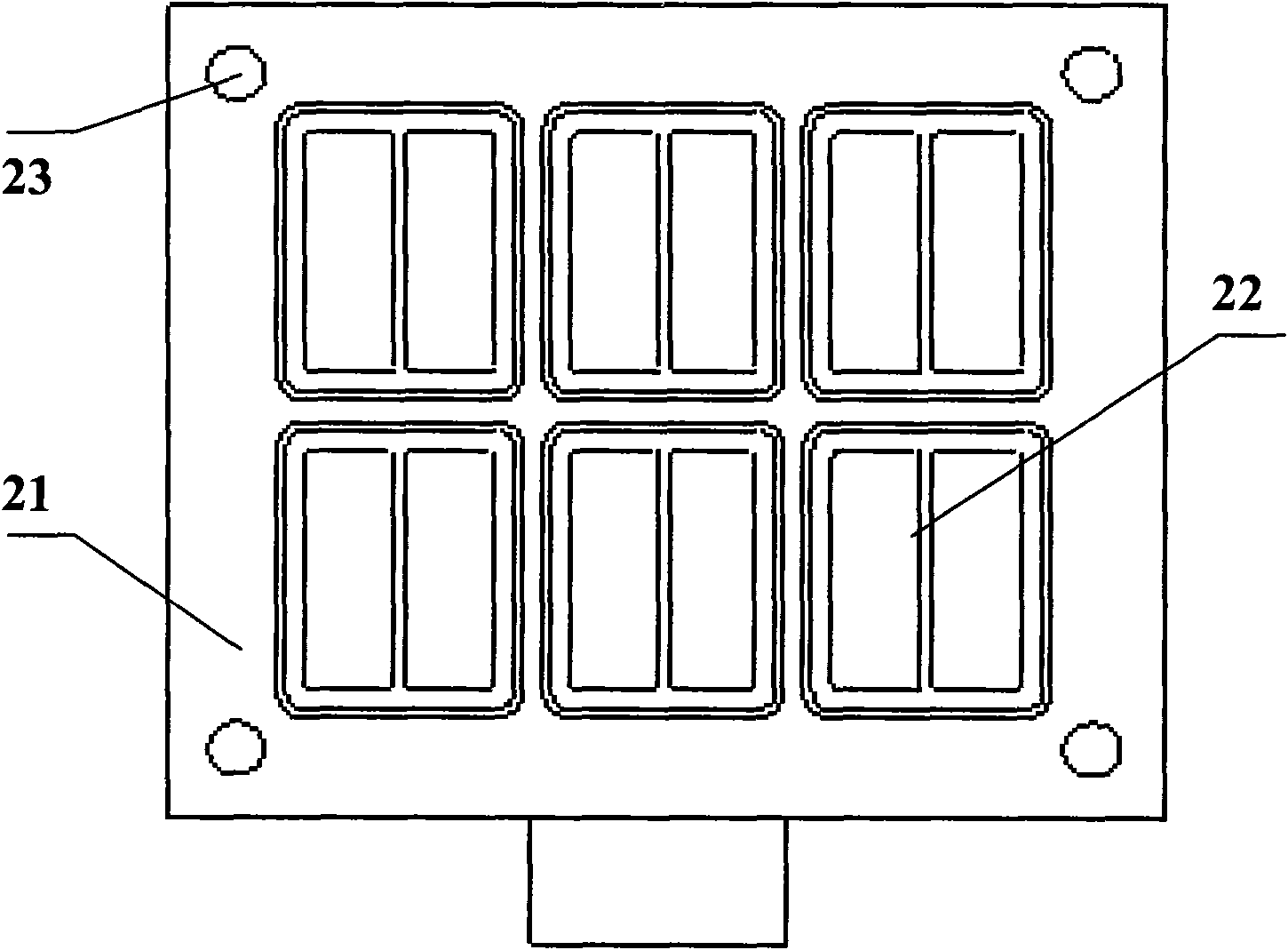

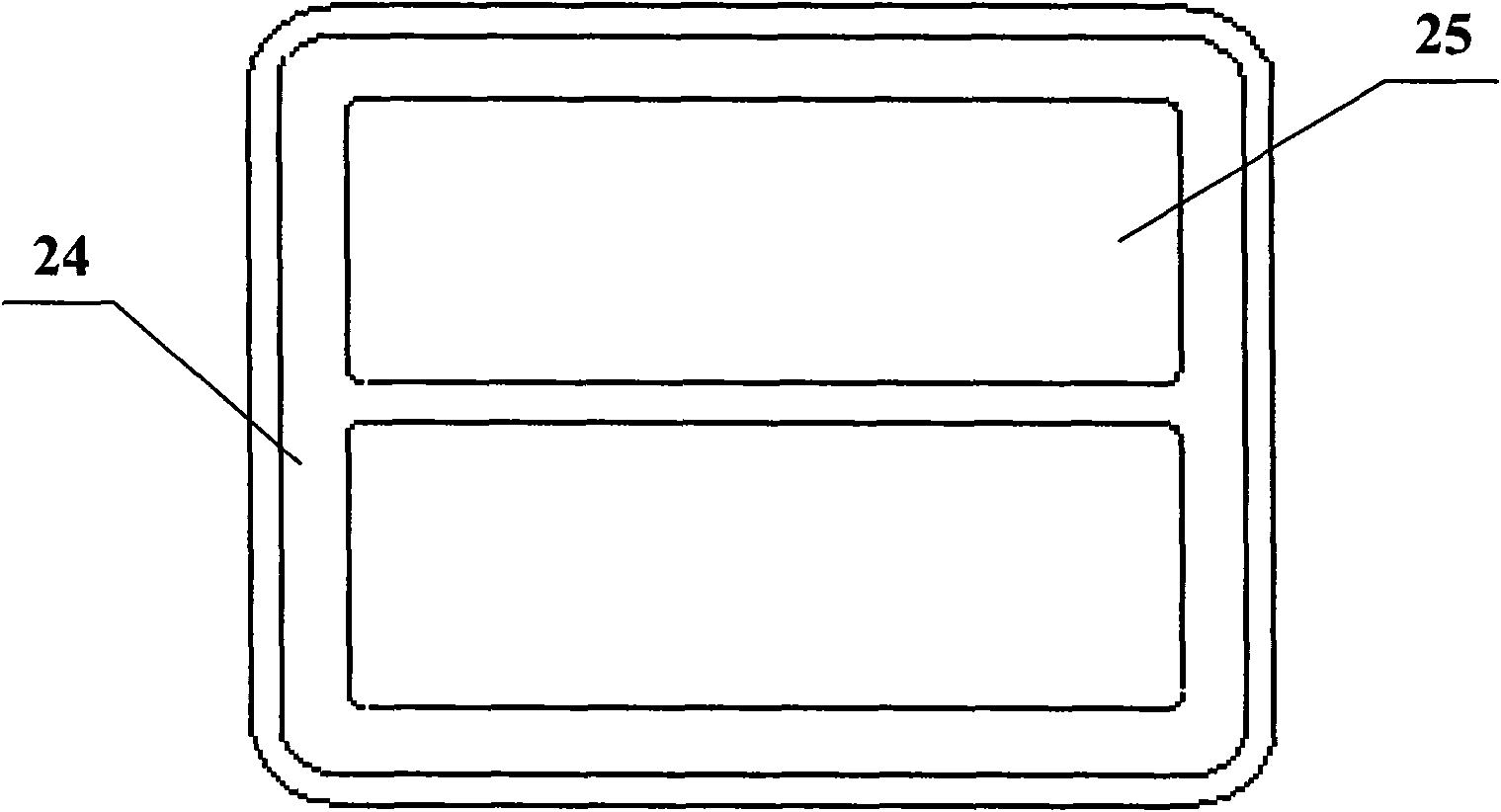

[0027] (1) Production and preparation of silica gel sheets: see figure 2 and image 3 , The fixed raw material formula and its accelerator processing settings will generate standard color and hardness preparations, which will be processed and printed after hydraulic molding by standard molds;

[0028] (2) Production and preparation of plastic keys: The standard thickness PC sheet is pre-baked and printed by infrared rays. After the punching oil pressure is completed, the formula, mesh density, color, color sample, operation procedure and control point are combined to complete the secondary printing and injection molding. Forming, processed by standard mold hydraulic forming;

[0029] (3) Production and preparation of shading sheet: After the black non-light-leakage fixed property film is subjected to leakage punching treatment, its edge is cut into a burr or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com