Method for manufacturing three-dimensional grid model by draft input

A technology of three-dimensional mesh and production method, which is applied in the field of three-dimensional modeling, and can solve the problems such as the inability to edit the outline of sketches, the inability to design complex models, and the inability to accurately control the shape of the three-dimensional model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

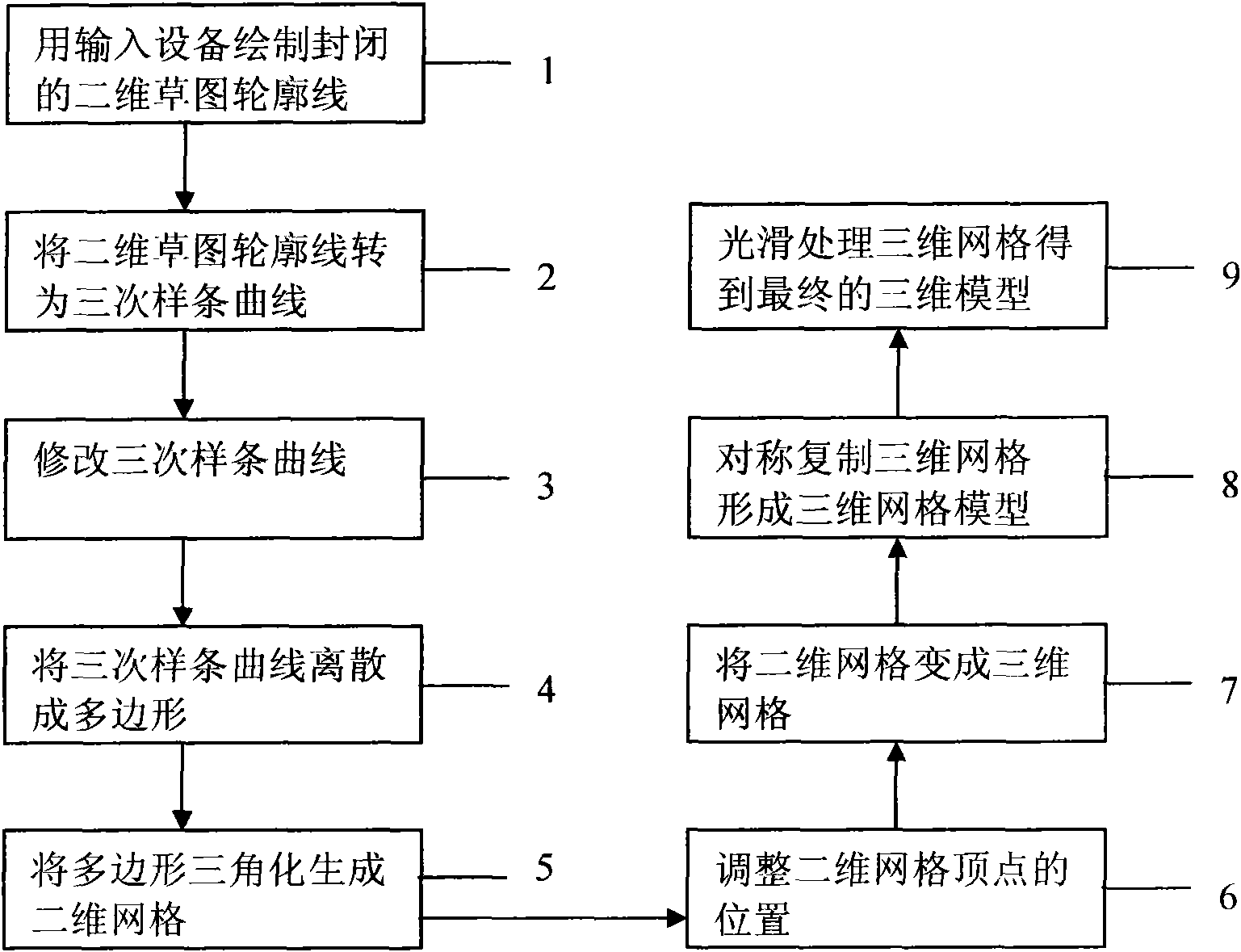

[0080] A method for making a 3D grid model with sketch input, its general steps can be found in figure 1 :

[0081] Step 1: Use the mouse or a drawing pen to draw a closed two-dimensional sketch outline on the computer screen, see figure 2 ; The closed two-dimensional sketch contour line is made up of several discrete length uneven line segments, and the endpoint position of the straight line segment is determined according to the position of the mouse or drawing pen when moving on the computer screen. The endpoint of the segment is the vertex of the 2D sketch outline;

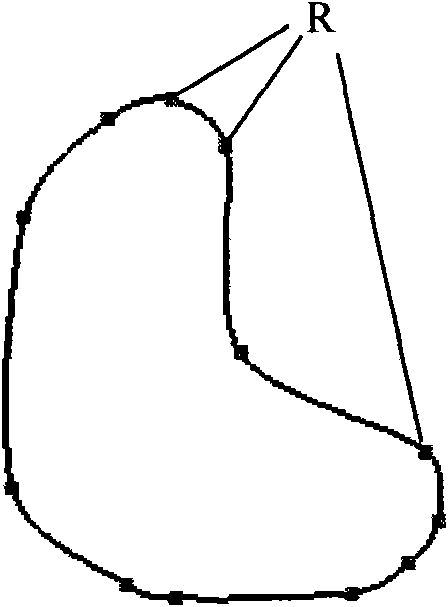

[0082] Step 2: Use the vertex reduction method and the Douglas-Peucker method to remove over-dense vertices, and convert the two-dimensional sketch outline into a cubic spline curve with control vertex R, see image 3 ;

[0083] Step 3: Change the shape of the cubic spline curve by moving, deleting or increasing the control vertex R of the cubic spline curve obtained in step 2), to obtain the expected contou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com