Method for realizing resource recovery of electroplating sludge

A technology for electroplating sludge and recycling, applied in the fields of chemistry and resources and environment, can solve problems such as secondary pollution, and achieve the effects of low investment and operating costs, high economic and environmental benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

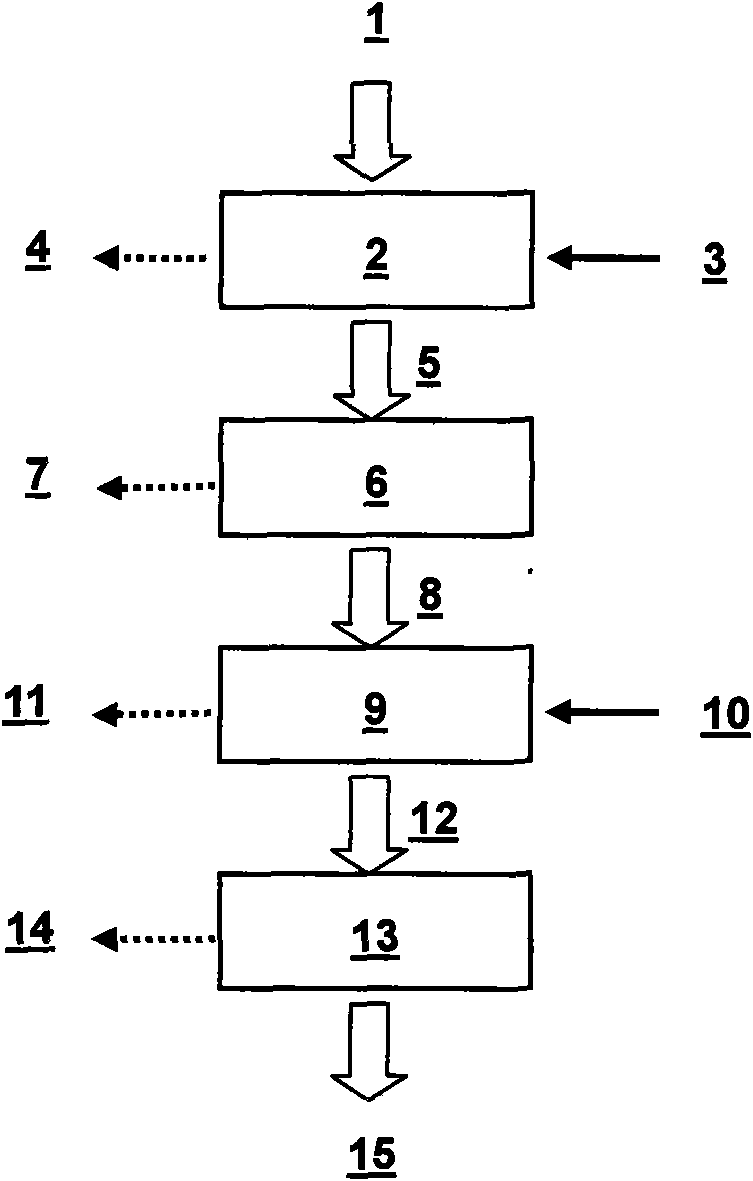

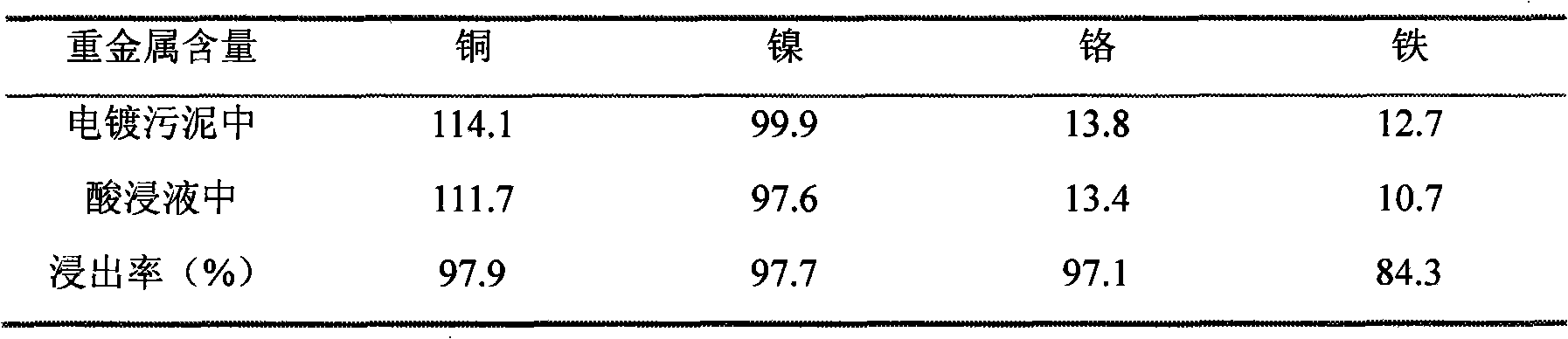

[0012] Combine below figure 1 The present invention is further described with embodiment, and purpose is to investigate the processing effect of the inventive method to actual electroplating sludge, and concrete implementation steps are as follows:

[0013] 1. Take 80g of dry electroplating sludge (1) in the acid leaching reactor (2), add 400mL of sulfuric acid with a concentration of 10%, shake and pickle for half an hour at room temperature, filter to obtain the acid leaching solution (5) and acid leaching residue (4). The pickling slag (4) is solidified, and the pickling solution (5) is added to the electrolytic cell (6).

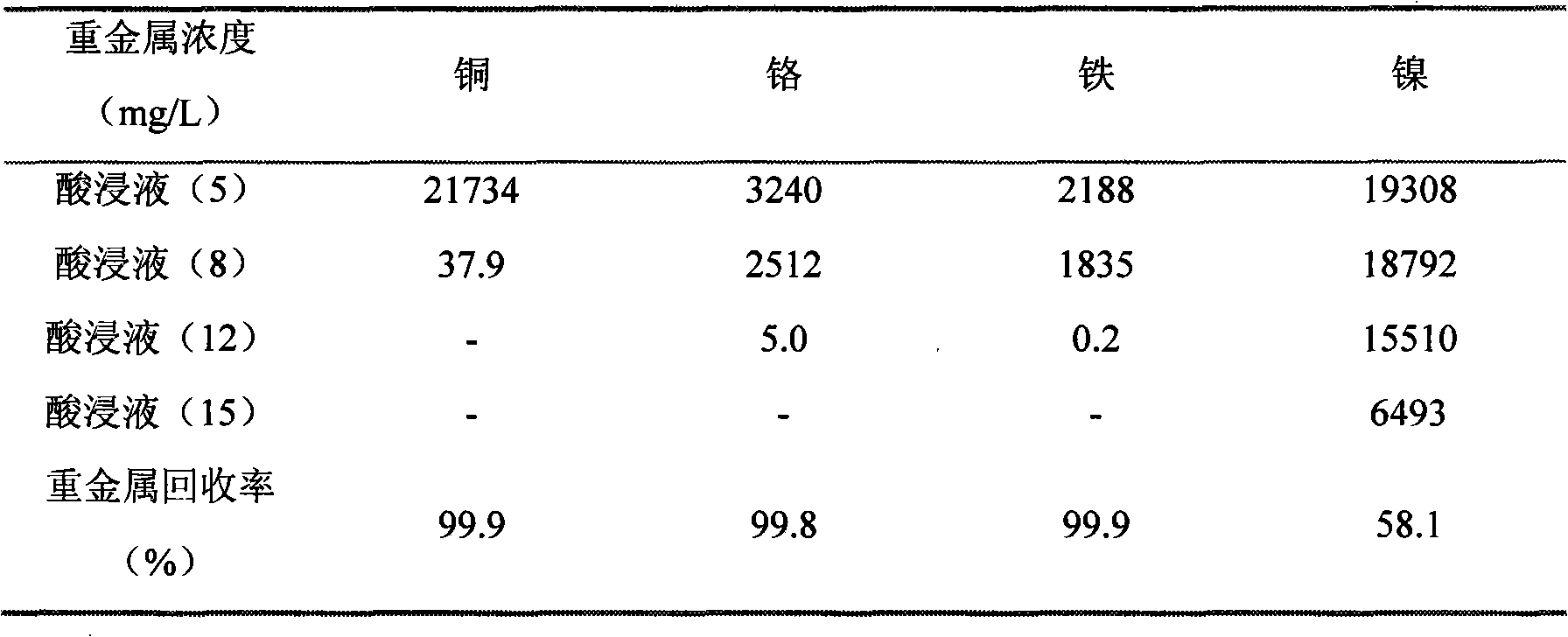

[0014] 2. In the electrolytic cell (6), a stainless steel cathode and a titanium-coated ruthenium-iridium anode are selected, and the cell voltage is selected to be 2.7V to obtain electrolytic copper (7).

[0015] 3. The acid leaching solution (8) after copper removal was adjusted to pH 1.6 with sodium hydroxide in the precipitation reactor (9), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com