Device for producing hydrogen through decomposing water

A hydrogen production device and water splitting technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low efficiency, not conducive to the full use of sunlight, and difficult separation of hydrogen and oxygen, so as to avoid reverse reactions and improve the utilization rate of solar energy , The effect of saving the cost of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

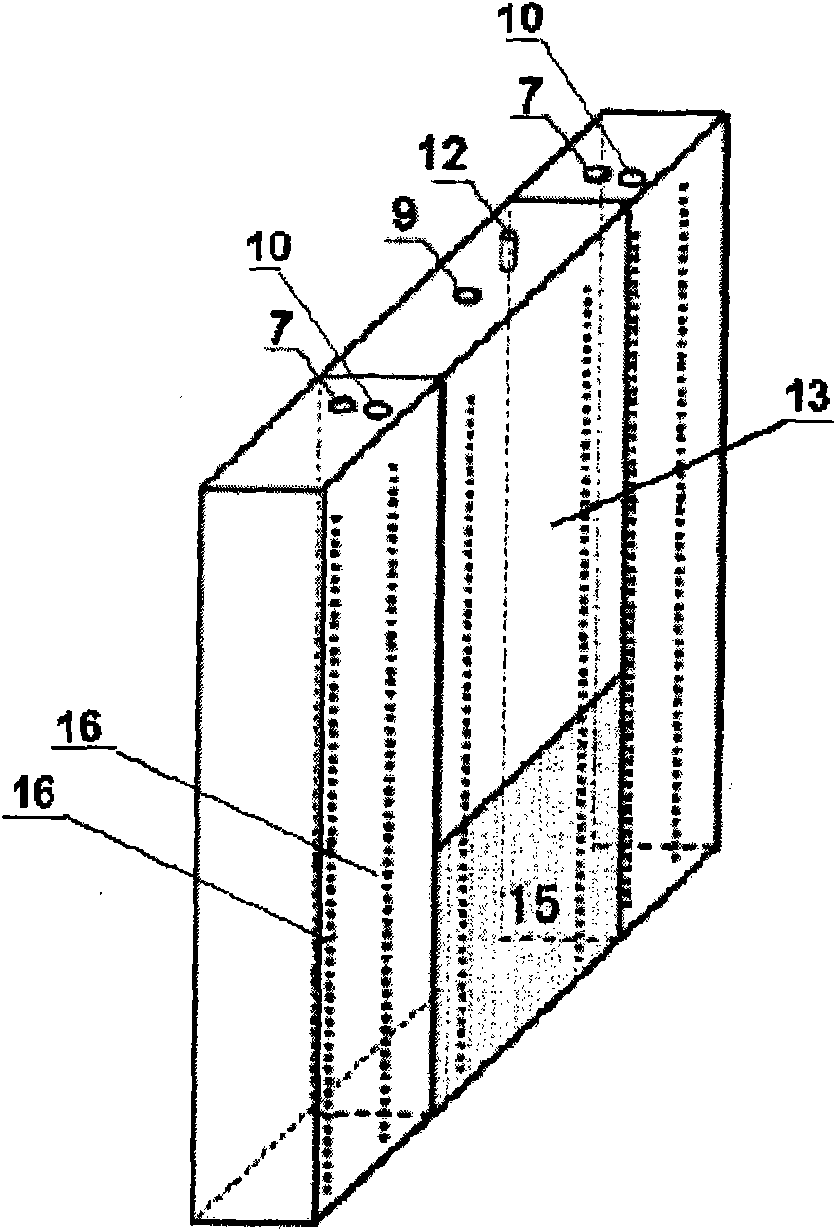

[0029] Preparation Example 1 (PEC photoanode (WO 3 Preparation of film samples))

[0030] A metal tungsten sheet with a thickness of about 1mm was placed in a tube furnace (OTF-1200X, Hefei Kejing Material Technology Co., Ltd.), and burned at 810°C for 15 minutes in an oxygen atmosphere to form a layer of tungsten on its surface. WO of about 1.5 μm 3 Oxide film, take it out for use.

preparation Embodiment 2

[0031] Preparation Example 2 (PEC photoanode (carbon-doped TiO 2 Preparation of film samples))

[0032] Carbon-doped TiO using a magnetron sputtering apparatus (Beijing Chuangshi Chengna Technology Co., Ltd.) 2 Preparation of film samples. CO in a volumetric mixing ratio of 1:5:9 2 , O 2 Fluorine tin oxide (FTO) substrates were sputtered with Ti targets in a mixed gas atmosphere of Ar and Ar. The substrate temperature was maintained at 400° C., and sputtering was performed at a power of 300 W for 2 hours, so that the thickness of the sputtered layer was 500 nm. The samples were then removed for use.

preparation Embodiment 3

[0033] Preparation Example 3 (preparation of dye-sensitized battery)

[0034] In an area of 9cm 2 A layer of TiO with a thickness of 2um and a particle size of 20nm was scraped on the FTO substrate 2granular layer. Then, the FTO substrate was immersed in an ethanol solution of N719 dye (Dalian Qiseguang Solar Technology Development Co., Ltd.) with a concentration of 20 mg / L, and was taken out after 24 hours to dry at room temperature. The above-treated FTO substrate was used as a photoanode. Put another area of 9cm 2 The FTO substrate was pulled in an aqueous solution of chloroplatinic acid with a concentration of 0.01 mole / liter using a pulling machine (TL0.01, Shenyang Kejing Equipment Manufacturing Co., Ltd.), and then heated in a muffle furnace (SX-4-10 , Tianjin Tester Instrument Co., Ltd.) for 2 hours to form a Pt layer with a thickness of 200 nm on the FTO substrate. This FTO substrate was used as a counter electrode. The dye side of the photoanode is then enc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com