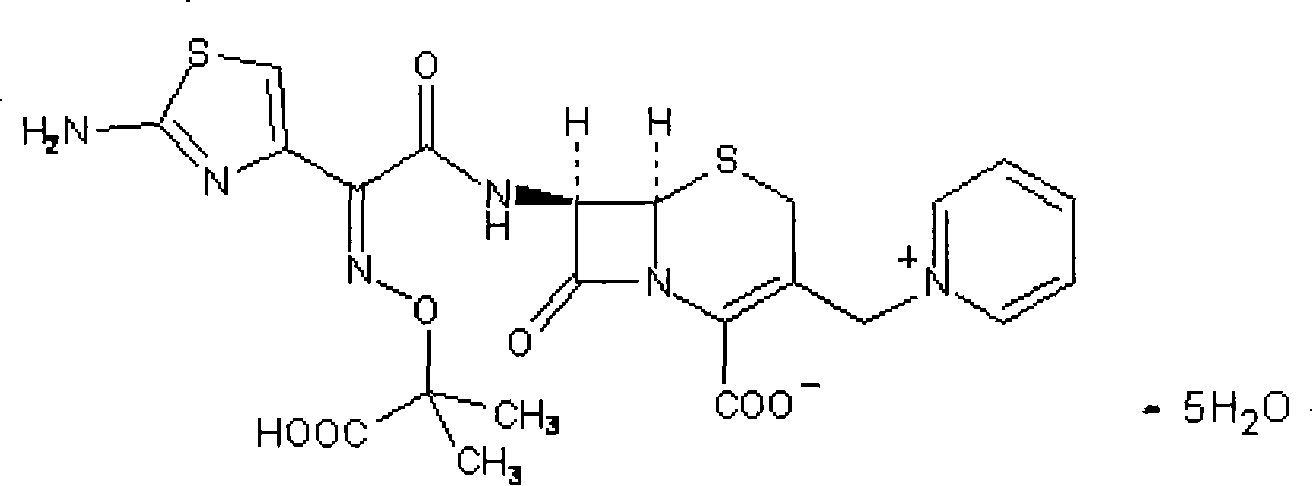

Method for preparing ceftazidime pentahydrate

A technology for ceftazidime and pentahydrate, which is applied in the field of preparation of ceftazidime pentahydrate, can solve the problems of high content of impurities and polymers, complicated operation, poor crystal form and the like, and achieves the effects of high yield, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of ceftazidime pentahydrate, carried out according to the following steps:

[0029] Step 1. Inject 30ml of water for injection into the dissolving tank, add 18g of ceftazidime hydrochloride, after dissolving, put in 0.5g of activated carbon, decolorize for 30 minutes, filter, and the filtrate is set aside;

[0030] Step 2, inject 45ml of water for injection into another dissolving tank, add 25g of ceftazidime hydrochloride, after dissolving, put in 0.5g of activated carbon, decolorize for 30 minutes, filter, and transfer the filtrate to a crystallization tank;

[0031] Step 3. Add dropwise the equivalent concentration of 3N sodium hydroxide solution to the crystallization tank in the second step, adjust the pH to 4.8, then add the filtrate in the first step dropwise to adjust the pH value to 3.6, and keep the temperature at 0-10°C , stirred, crystallized;

[0032] Step 4: After growing the crystal for 3-4 hours, filter, wash the filter cake twice w...

Embodiment 2

[0035] A preparation method of ceftazidime pentahydrate, carried out according to the following steps:

[0036] Step 1. Inject 60ml of water for injection into the dissolving tank, add 37g of ceftazidime hydrochloride, after dissolving, put in 1.5g of activated carbon, decolorize for 30 minutes, filter, and the filtrate is set aside;

[0037] Step 2, inject 100ml of water for injection into another dissolving tank, add 54g of ceftazidime hydrochloride, after dissolving, put in 1.5g of activated carbon, decolorize for 30 minutes, filter, and transfer the filtrate to a crystallization tank;

[0038] Step 3. Add 20% sodium carbonate solution dropwise to the crystallization tank in the second step, adjust the pH value to 5.0, then add the filtrate in the first step dropwise to bring the pH value back to 3.6, keep the temperature at 0-10°C, and stir ,crystallization;

[0039] Step 4: After growing the crystal for 3-4 hours, filter, wash the filter cake twice with cold water and ac...

Embodiment 3

[0042] A preparation method of ceftazidime pentahydrate, carried out according to the following steps:

[0043] Step 1. Inject 50ml of water for injection into the dissolving tank, add 32g of ceftazidime hydrochloride, after dissolving, put in 1.5g of activated carbon, decolorize for 30 minutes, filter, and the filtrate is set aside;

[0044] Step 2, inject 80ml of water for injection into another dissolution tank, add 48g of ceftazime hydrochloride, after dissolving, put in 1.5g of activated carbon, decolorize for 30 minutes, filter, and transfer the filtrate to a crystallization tank;

[0045] Step 3, add 8% sodium bicarbonate solution dropwise to the crystallization tank in the second step, adjust the pH value to 5.3, then add the filtrate in the first step dropwise to bring the pH value back to 3.6, and keep the temperature at 0-10°C, stir, crystallize;

[0046] Step 4: After growing the crystal for 3-4 hours, filter, wash the filter cake twice with cold water and acetone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com