Control method of injection molding and control apparatus of injection molding

A technology of injection molding and control methods, which is applied in the field of injection molding control and injection molding control devices, can solve the problems of shortening mold life, pressure punching, and increasing the clamping force of injection molding machines, so as to prevent overfilling and prevent injection The effect of pressure overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

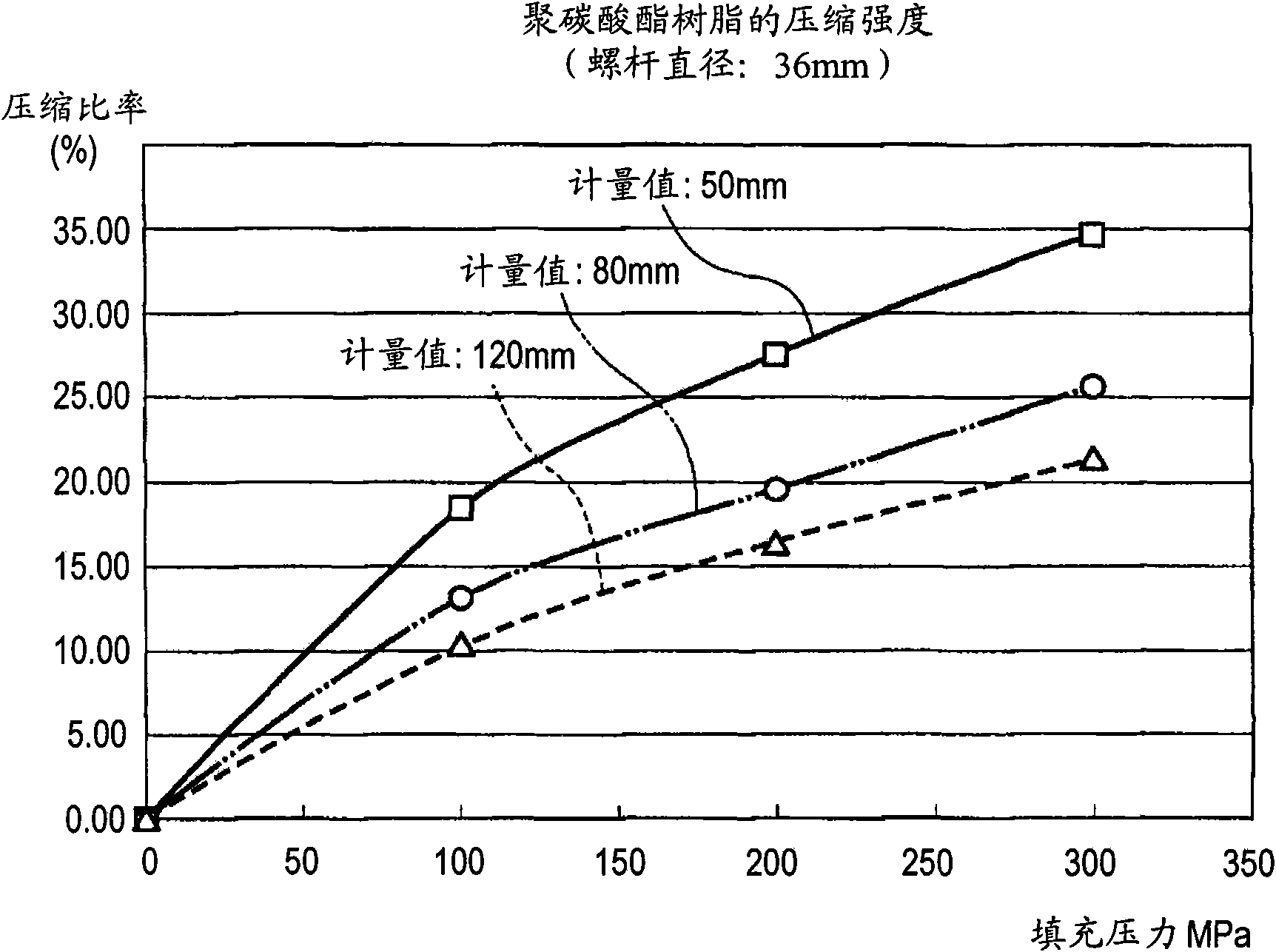

[0033] figure 2 is a graph showing material data obtained from experiments performed to describe the compressive strength of the molded material constituting the principle of the present invention. In this experiment, PC (polycarbonate) was used as a molding material of a screw in-line injection molding machine actually used. The gauge values (stroke of the screw) for a screw with a diameter of 36 mm were set at 50 mm, 80 mm and 120 mm. Record the pressure of the molding material and the position of the screw when injecting the molding material under the conditions specified above. The results obtained by calculating the compressive strength of the molding material PC based on the recorded data are plotted in figure 2 on the graph of . exist figure 2 In , the abscissa is for the filling pressure (MPa), and the ordinate is for the compression ratio (%).

[0034] refer to figure 2 , the relationship between filling pressure and compression ratio changes linearly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com