Vacuum expendable pattern casting (V-EPC) molding method of large complex castings

A vacuum lost foam, complex technology, applied in the direction of casting molding equipment, molds, cores, etc., can solve the problem of complex modeling, up to several tons, ten tons or even twenty tons, and achieve the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below:

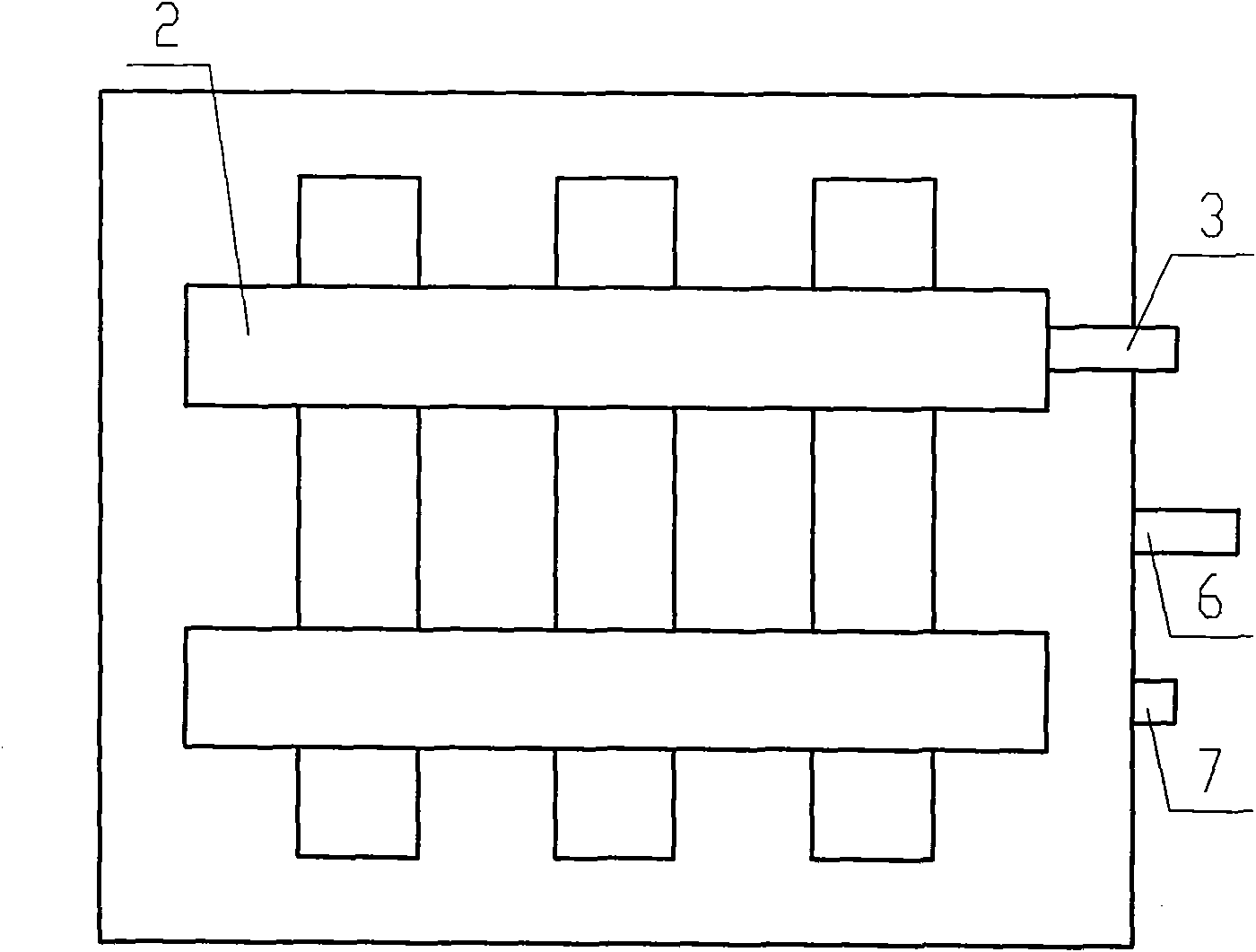

[0023] When producing the base of a stamping model, its casting dimensions are 1m × 2m × 6m, and its weight is 15 tons. There are multiple grooves on the base, and connecting ribs are formed between the grooves. When vacuum lost foam casting is used, a real mold that is consistent with the base is prefabricated with foam. The real mold is generally manufactured by the design unit. After reaching the foundry, the real mold is first painted and dried twice. Then bury the box, vibrate for molding, and vacuumize after the molding is completed, and then pouring can be carried out.

[0024]Among them, the sand box used for modeling adopts a combined sand box with a movable bottom and a movable cover. The sand box includes three parts: the bottom of the sand box, the sand box body, and the upper suction lifting pressure bar. The bottom of the sand box is set under the sand box body and moves with the sand box body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com