Lipstick with high water content and preparation method thereof

A high water content, lip balm technology, applied in the field of personal care products, can solve the problems of low water content of lipstick and difficulty in adding water-soluble active ingredients, and achieve good shape stability, soft touch, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]

[0034]

[0035] Note: Phase A is the oil phase component and emulsifier of the water-in-oil pre-emulsion, phase B is the water phase component, and phase C is the oil phase component.

[0036] The steps for preparing the above-mentioned products are as follows:

[0037] 1. Prepare water-in-oil pre-emulsion at room temperature:

[0038] First add 5wt% WE 09 with 2wt% CT is mixed at room temperature and stirred evenly; then the water phase component (a mixture of water and glycerin) is added dropwise, and stirred continuously while adding to obtain a water-in-oil pre-emulsion.

[0039] 2. Mix the remaining oil phase component C evenly and heat to 70°C.

[0040] 3. Add the water-in-oil pre-emulsion to the oil phase components, stir slowly to disperse it evenly, keep the temperature of the mixture at 85°C, and keep stirring to make it evenly mixed.

[0041] 4. Injection mold at 80°C, cool to room temperature and place in -15°C refrigerator for 45 minutes to fo...

Embodiment 2

[0045]

[0046]

[0047] Note: Phase A is the oil phase component and emulsifier of the water-in-oil pre-emulsion, phase B is the water phase component, and phase C is the oil phase component.

[0048] The product of Example 2 was prepared according to the procedure of Example 1 using the components and amounts shown in the table above.

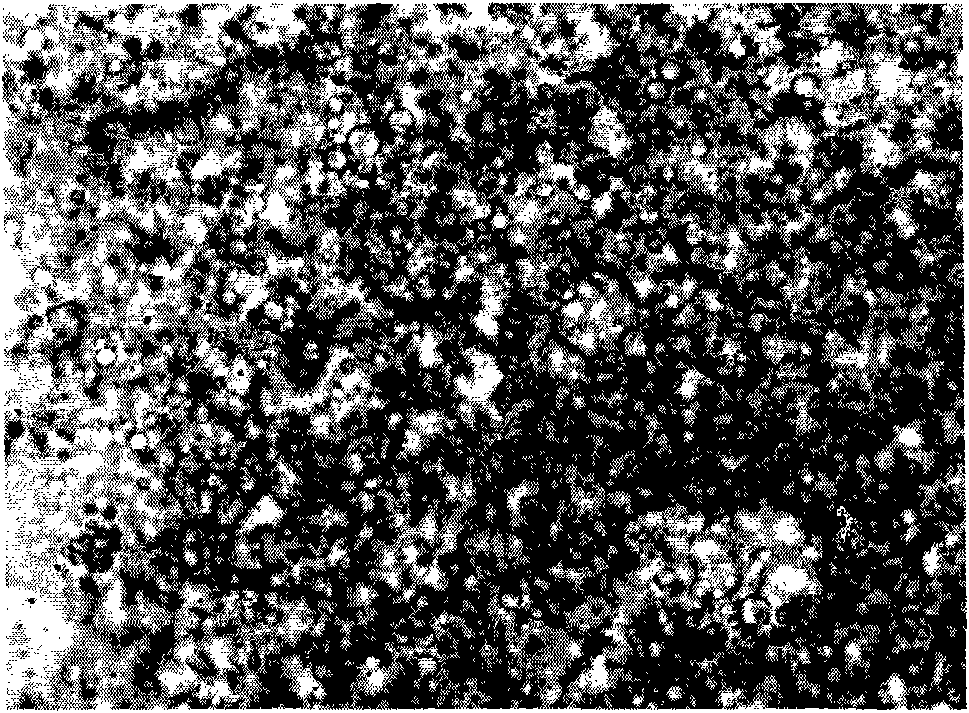

[0049] image 3 A magnified 400-fold photomicrograph of a thin layer of a high-moisture content lipstick with a water content of 30 wt% prepared for Example 2 applied to a glass slide. It can be seen from the photos that the interior of the lipstick sample is uniform, and the water phase is also uniformly distributed in the form of round particles.

Embodiment 3

[0051]

[0052]

[0053] Note: Phase A is the oil phase component and emulsifier of the water-in-oil pre-emulsion, phase B is the water phase component, phase C is the oil phase component, phase D is the pigment component, and phase E is the pearlescent component.

[0054] The steps for preparing the above-mentioned products are as follows:

[0055] 1. Prepare water-in-oil pre-emulsion at room temperature:

[0056] First add 4.4wt% WE 09 with 1.76wt% CT is mixed at room temperature and stirred evenly; then the water phase component (mixture of water and glycerin) is added dropwise, and stirred continuously while adding to keep the mixture in an emulsified state to obtain a water-in-oil pre-emulsion.

[0057] 2. Mix the remaining oil phase component C evenly and heat to 90°C.

[0058] 3. Add the water-in-oil pre-emulsion to the oil phase component C obtained in step 2, stir slowly to disperse it evenly, keep the temperature of the mixture at 85°C, and keep stirring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com