Spiral-flow auxiliary air intake device and compression pump thereof

An air intake device and swirl-type technology, applied in the field of compression pumps, can solve problems affecting the working efficiency of compression pumps, limiting gas input flow, passive gas input, etc., to improve work efficiency, increase intake flow, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

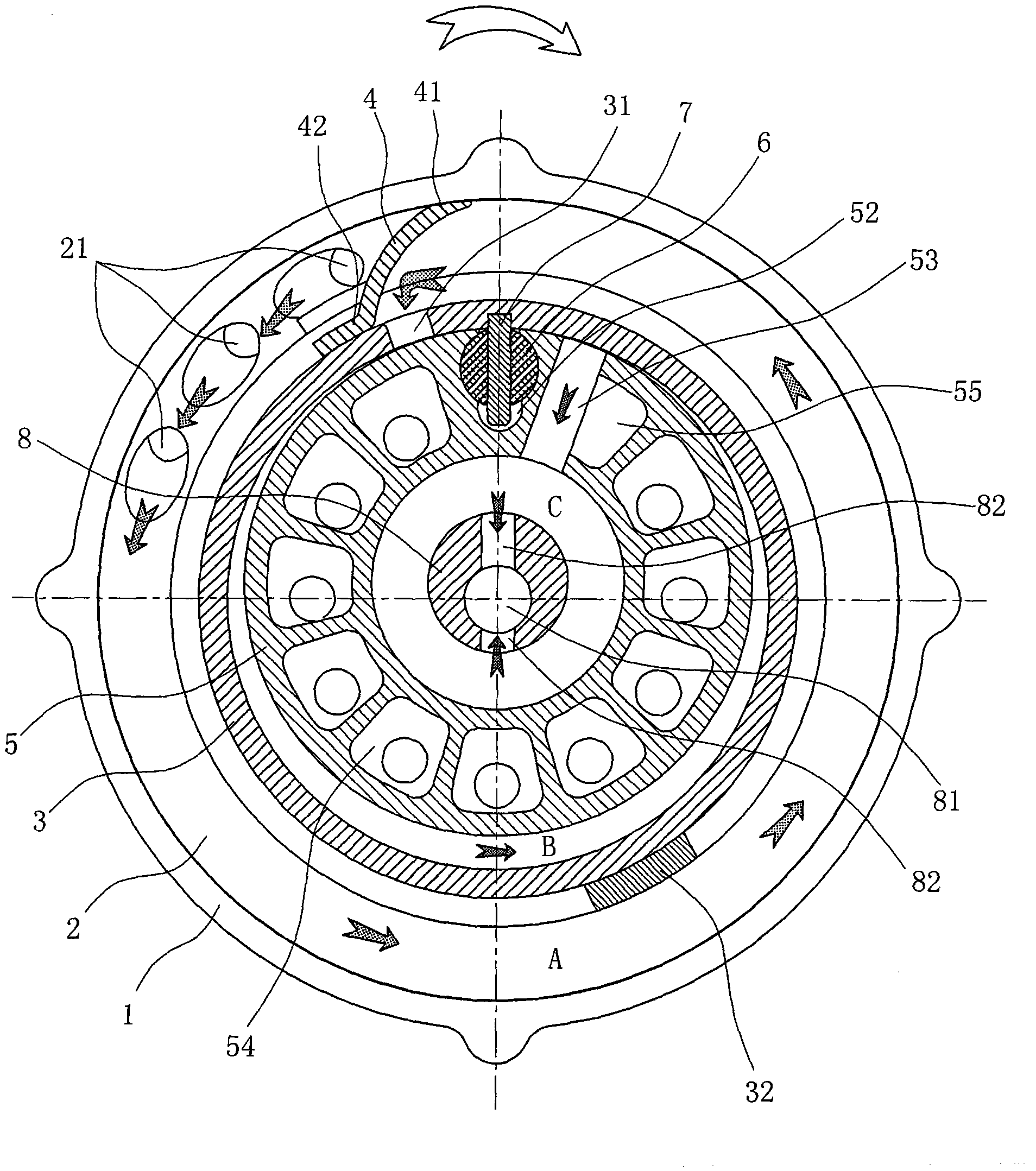

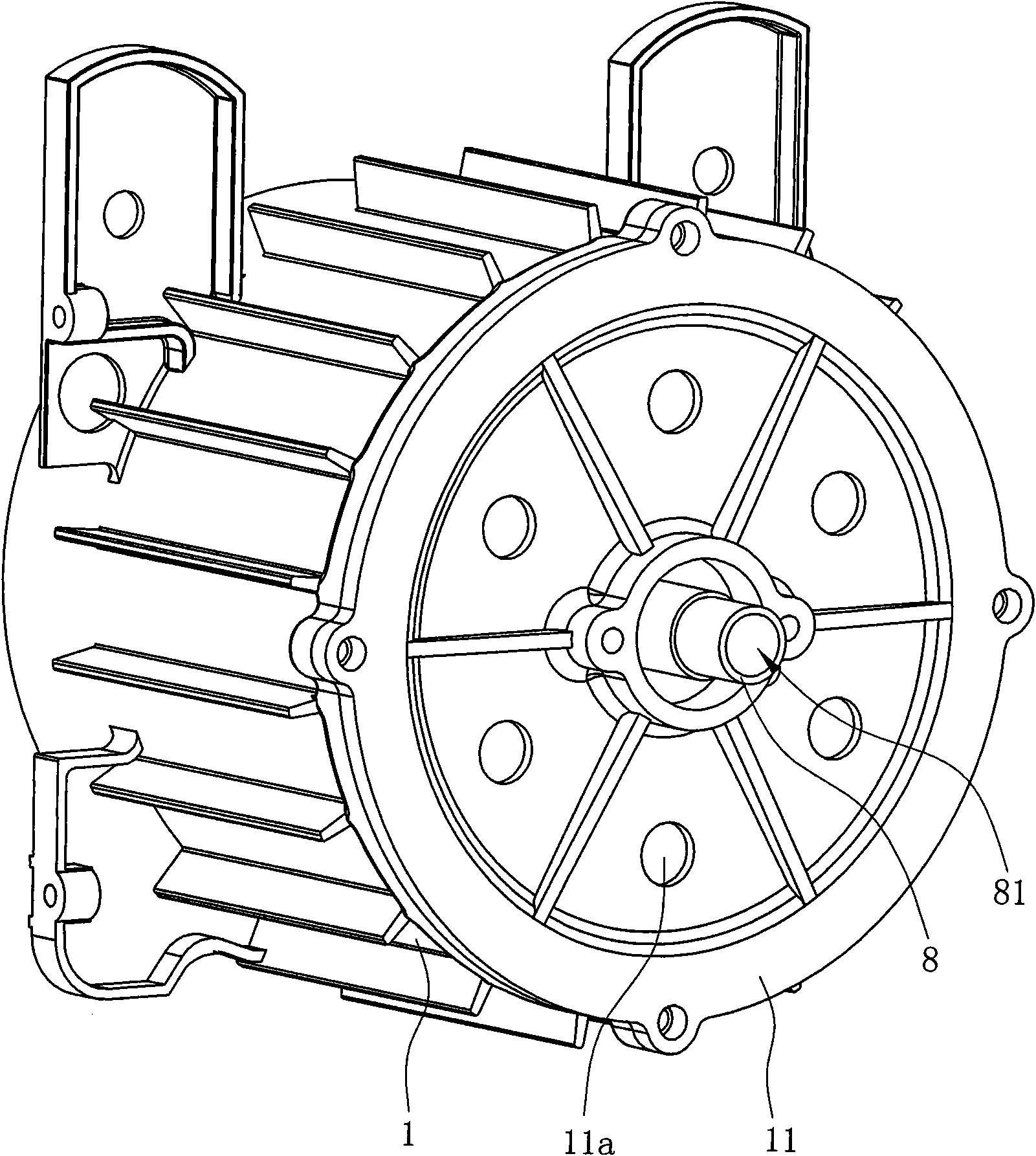

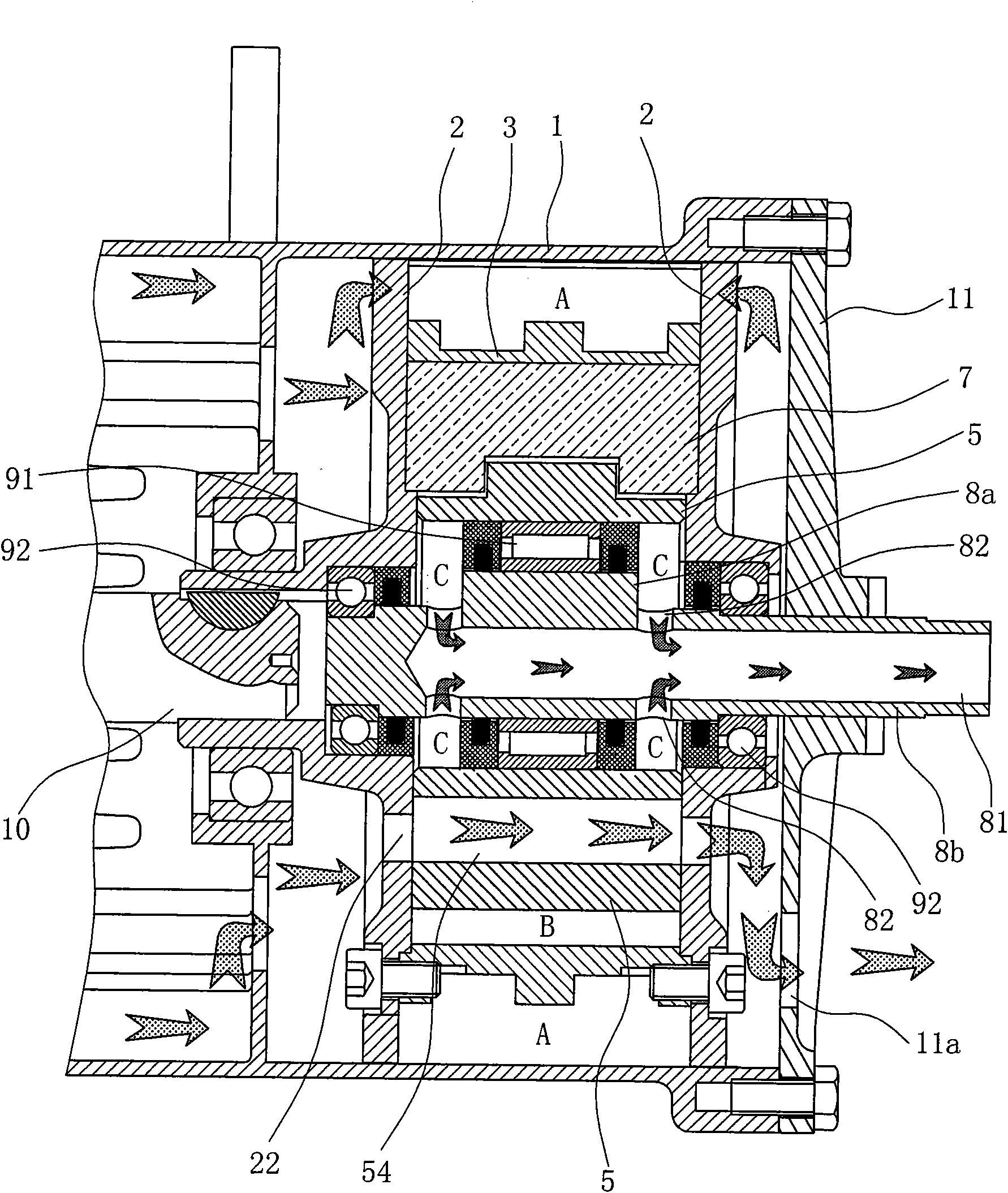

[0033] Such as Figure 1 to Figure 7 As shown, it is a preferred embodiment of the compression pump applied with the swirl type auxiliary air intake device in the present invention. The compression pump includes a pump casing 1 with a cylindrical cavity, a cylindrical cylinder 3, a hollow rotor 5 arranged in the cylinder 3, a cock 6, a follower partition 7, a guide arranged in the center of the rotor 5 Air shaft 8 and a swirl type auxiliary air intake device.

[0034] Wherein, when this embodiment is applied to the compressor, the end of the pump housing 1 is provided with a machine cover 11 with an air vent 11a, see figure 2 with image 3 .

[0035] The cylinder body 3 is coaxially arranged in the pump casing 1 and has a distance from the pump casing 1. The cavity between the cylinder body 3 and the pump casing 1 is the swirl air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com