Jet pump for internal-combustion engine and internal-combustion engine having the jet pump

A technology for injection pumps and internal combustion engines, applied in the fields of injection pumps and internal combustion engines, which can solve problems such as suction hole damage and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

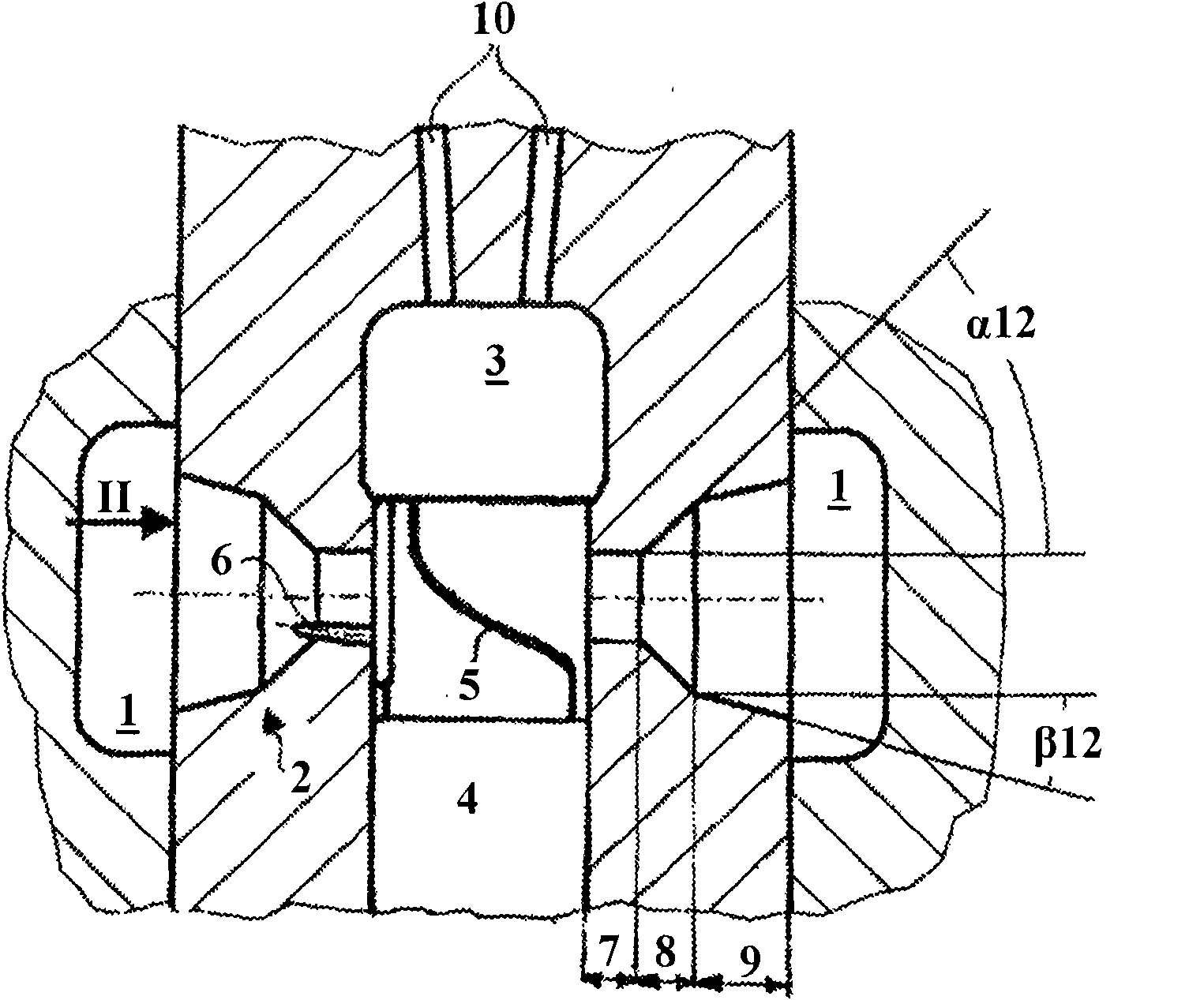

[0048] figure 1 Shown in axial section is a part of an injection pump for an internal combustion engine (not shown) according to an embodiment of the invention, the injection pump having a suction chamber 1 which is distributed by means of a pre-delivery system (not shown) with fuel under high pressure. The injection pump also has a high-pressure chamber 3 in which fuel is brought under injection pressure via a piston 4 and delivered via a line 10 to a combustion chamber of an internal combustion engine (not shown).

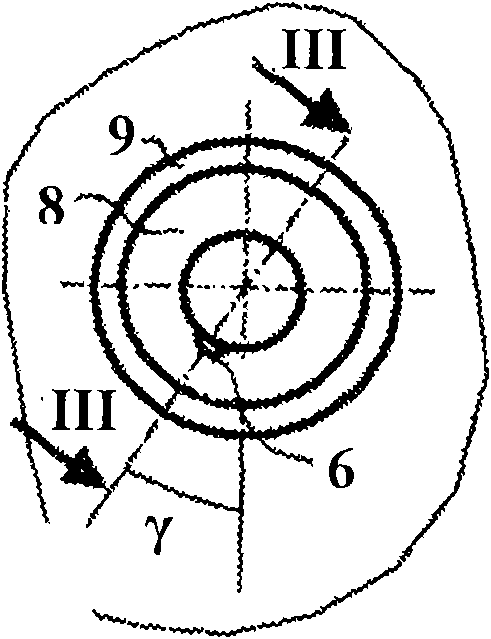

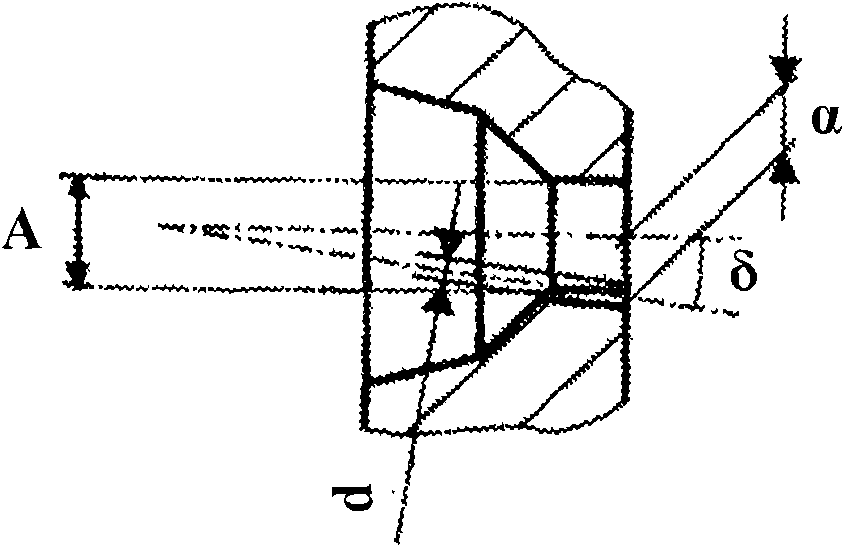

[0049] The suction chamber communicates with the high pressure chamber through a suction hole assembly with two suction holes 2 . Up to this point, the intake opening 2 , which has been congruently configured, has two frustoconical sections 8 , 9 . The opening angle α of the frustum section 8 close to the piston 4 is greater (approximately 25°) than the opening angle β of the frustum section 9 remote from the piston, which is approximately 9° in the exemplary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com