Method for preparing aluminum phosphate molecular screen in eutectic mixture

A eutectic mixture, aluminum phosphate molecular sieve technology, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve and alkali-exchanged phosphate, phosphorus compounds, etc., can solve the problem that the template effect of quaternary ammonium salt component cannot be exerted, and limit the aluminum phosphate molecular sieve and other problems, to achieve the effect of not easy to deliquescence and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

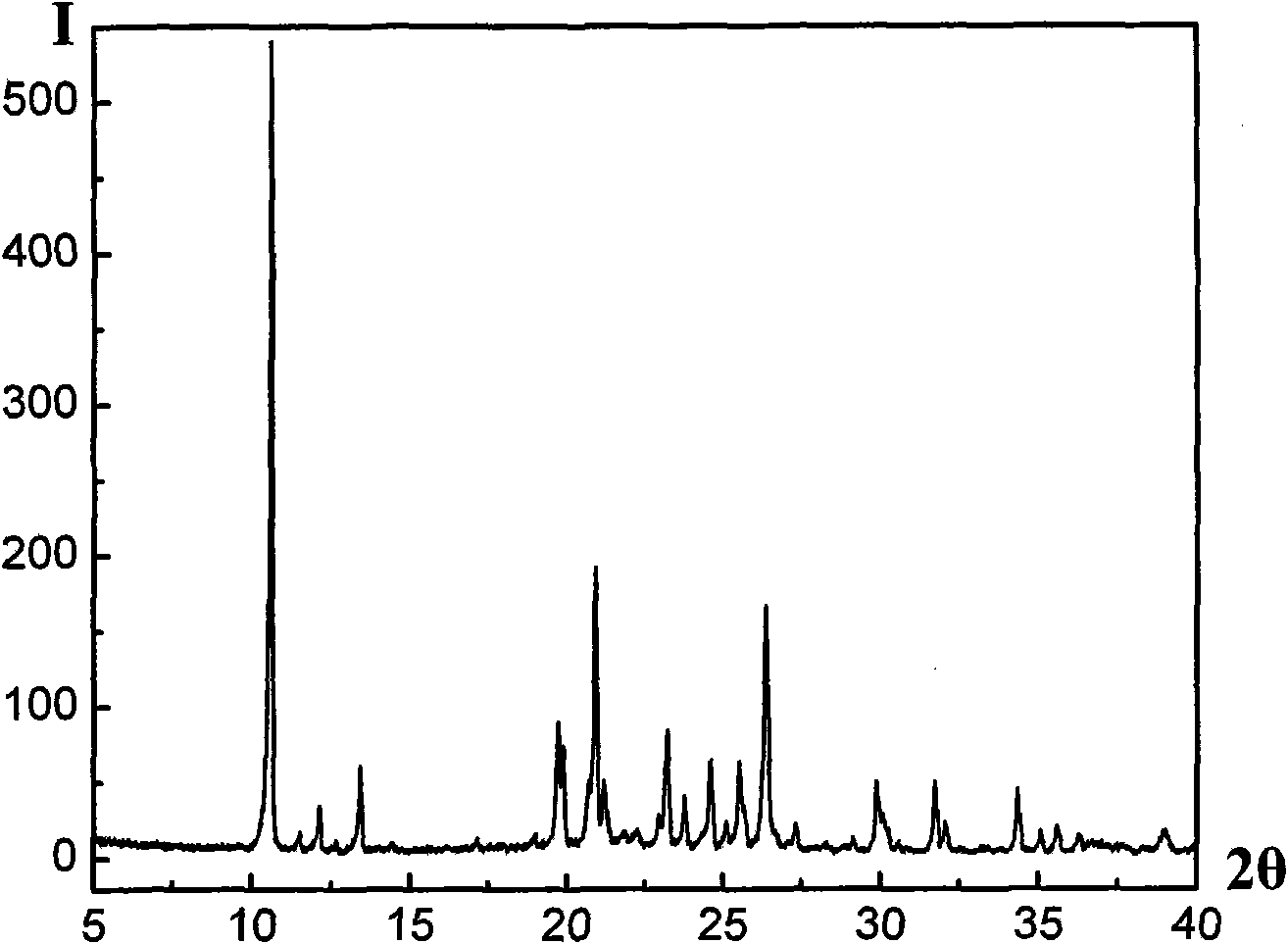

[0024] 2.7g of pentaerythritol and 1.5g of tetramethylammonium bromide (molar ratio is 2.0) are thoroughly ground in a mortar, and then the mixture of the two is placed in a beaker and heated at 130°C until it becomes transparent liquid, a eutectic mixture (DES) was obtained, which turned into a white solid after cooling to room temperature. At room temperature, the prepared 4.2g DES, 0.20gAl[OCH(CH 3 ) 2 ] 3 , 0.23 g H 3 PO 4 , 20μl HF was sequentially added to a 20ml polytetrafluoroethylene-lined stainless steel reactor, and the molar ratio of the final reactant was 0.5HF:1.0Al[OCH(CH 3 ) 2 ] 3 : 2.0H 3 PO 4 : 30DES, after sealing, the crystallization temperature is 180°C for 3 days, after the reaction, take out the reactor and cool to room temperature. The obtained crystallized product was taken out, washed with ethanol, filtered and dried. The final product is a ZON type aluminum phosphate molecular sieve, and its XRD spectrum is shown in the appendix figure 1 ...

Embodiment approach 2

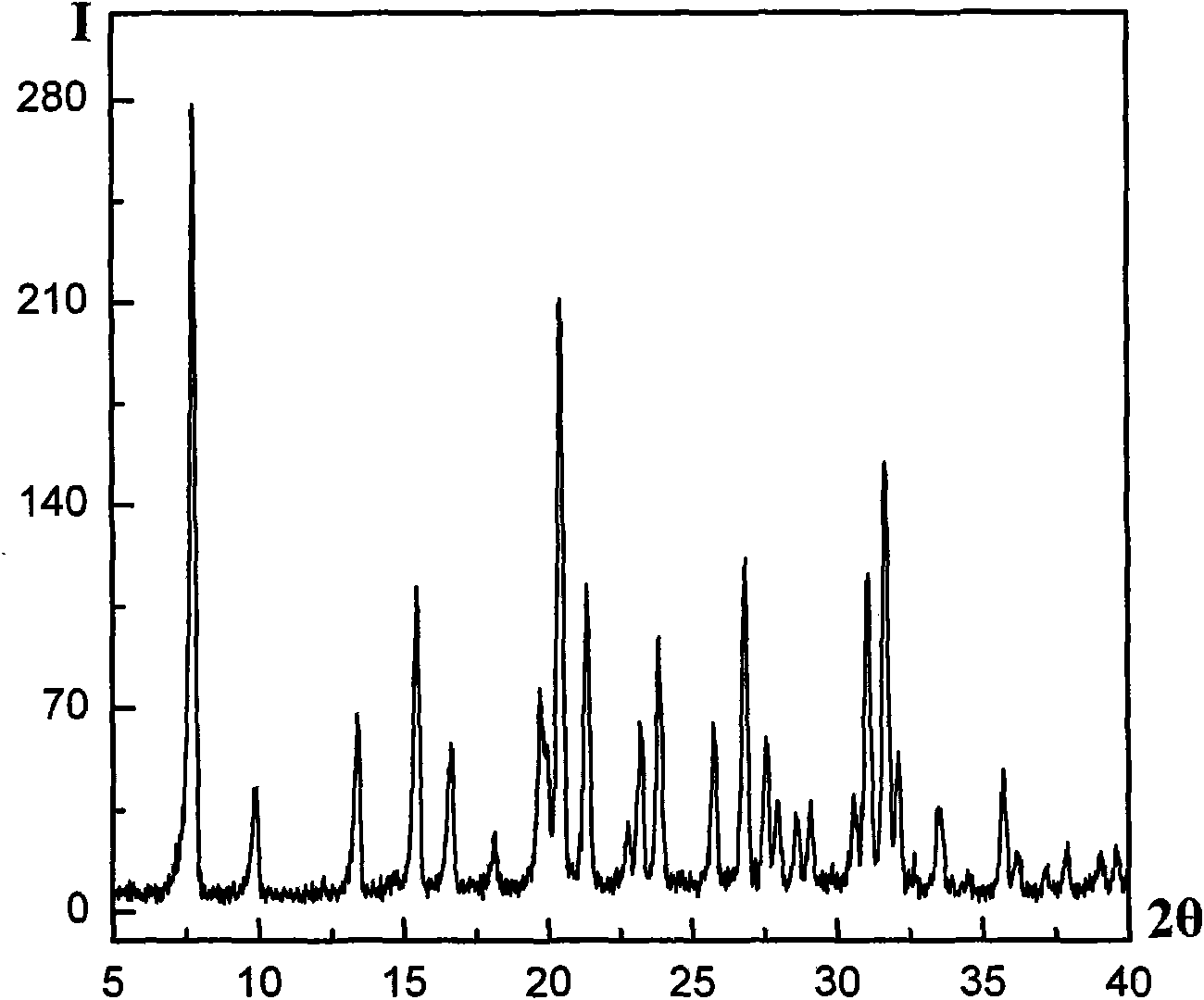

[0026] 2.0g of pentaerythritol and 2.2g of mepizom (molar ratio is 1.0) are thoroughly ground in a mortar, then the mixture of the two is placed in a beaker and heated at 130°C until it becomes a transparent liquid, then A eutectic mixture (DES) was obtained which became a white solid upon cooling to room temperature. At room temperature, the prepared 4.2g DES, 0.21g Al[OCH(CH 3 ) 2 ] 3 , 0.23 g H 3 PO 4 , 20μl HF was added to a 20ml polytetrafluoroethylene-lined stainless steel reaction kettle in turn, and the molar ratio of the final reactant was 0.5HF:1.0Al[OCH(CH 3 ) 2 ] 3 : 2.0H 3 PO 4 : 29DES, after sealing, the crystallization temperature was 180°C for 3 days, and after the reaction was completed, the reactor was taken out and cooled to room temperature. The obtained crystallized product was taken out, washed with ethanol, filtered and dried. The final product is an ERI aluminum phosphate molecular sieve, and its XRD spectrum is shown in the appendix of the sp...

Embodiment approach 3

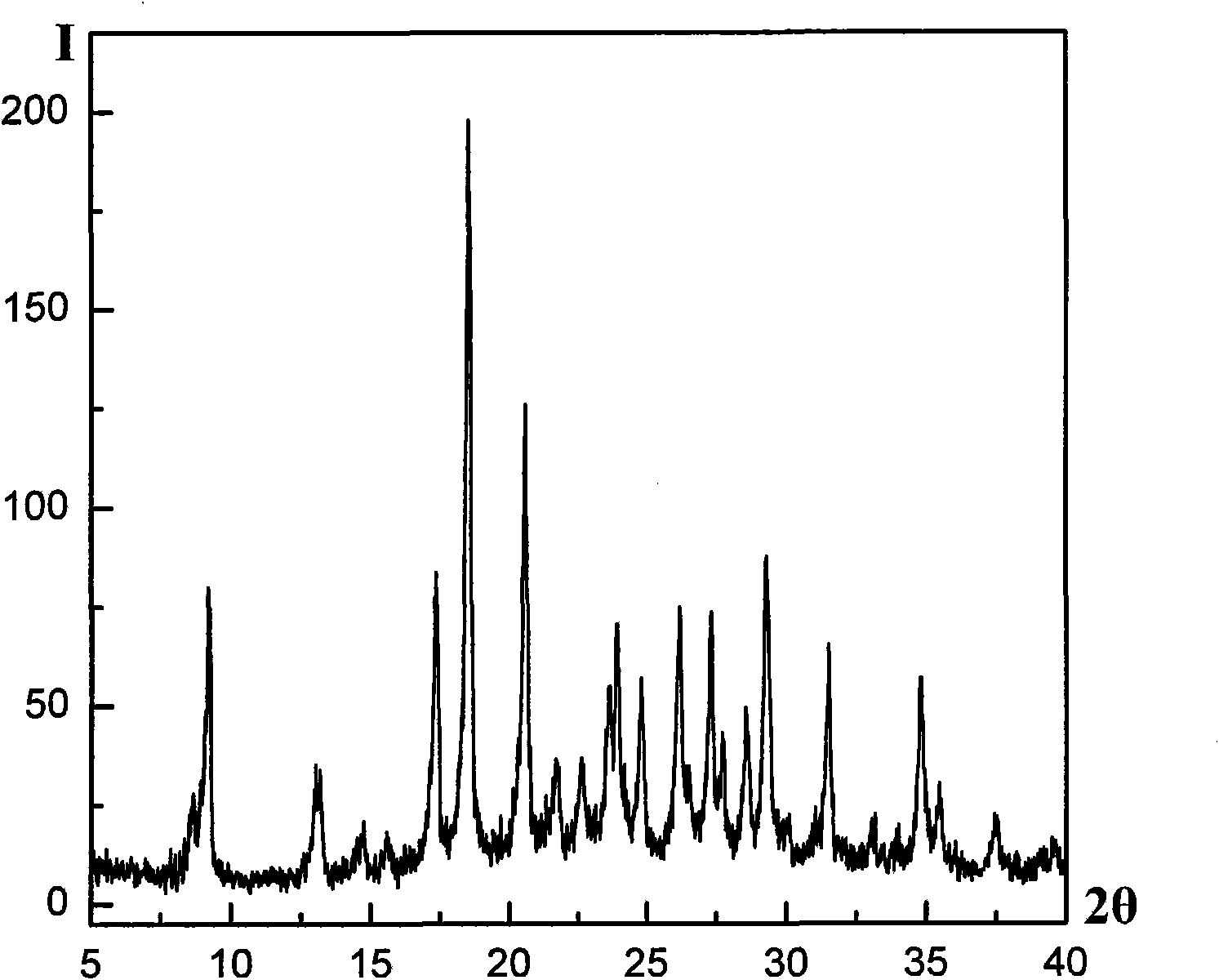

[0028] No HF was added to the initial reaction system, and the molar ratio of the final reactant was 1.0Al[OCH(CH 3 ) 2 ] 3 : 2.0H 3 PO 4 : 29DES, others are the same as embodiment 2, and the final product is an AWW type aluminum phosphate molecular sieve, and its XRD spectrogram is shown in the attached description image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com