Stone thermal insulating composite panel

A thermal insulation composite board and composite board technology, applied in the direction of thermal insulation, building materials, building components, etc., can solve the problems of low hardness of inorganic boards, impact on house safety, poor thermal insulation function, etc. And the comprehensive cost of installation is low, and the effect of heat preservation and fire resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

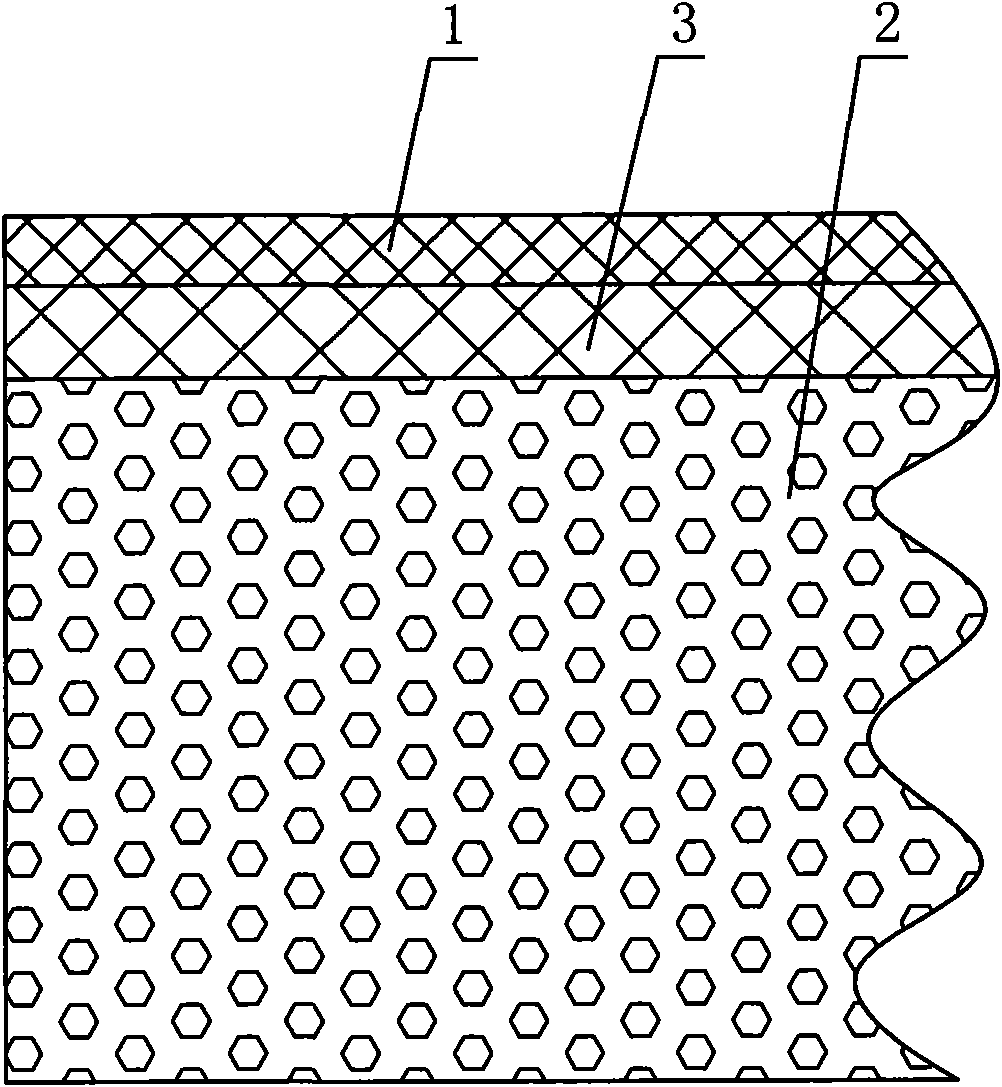

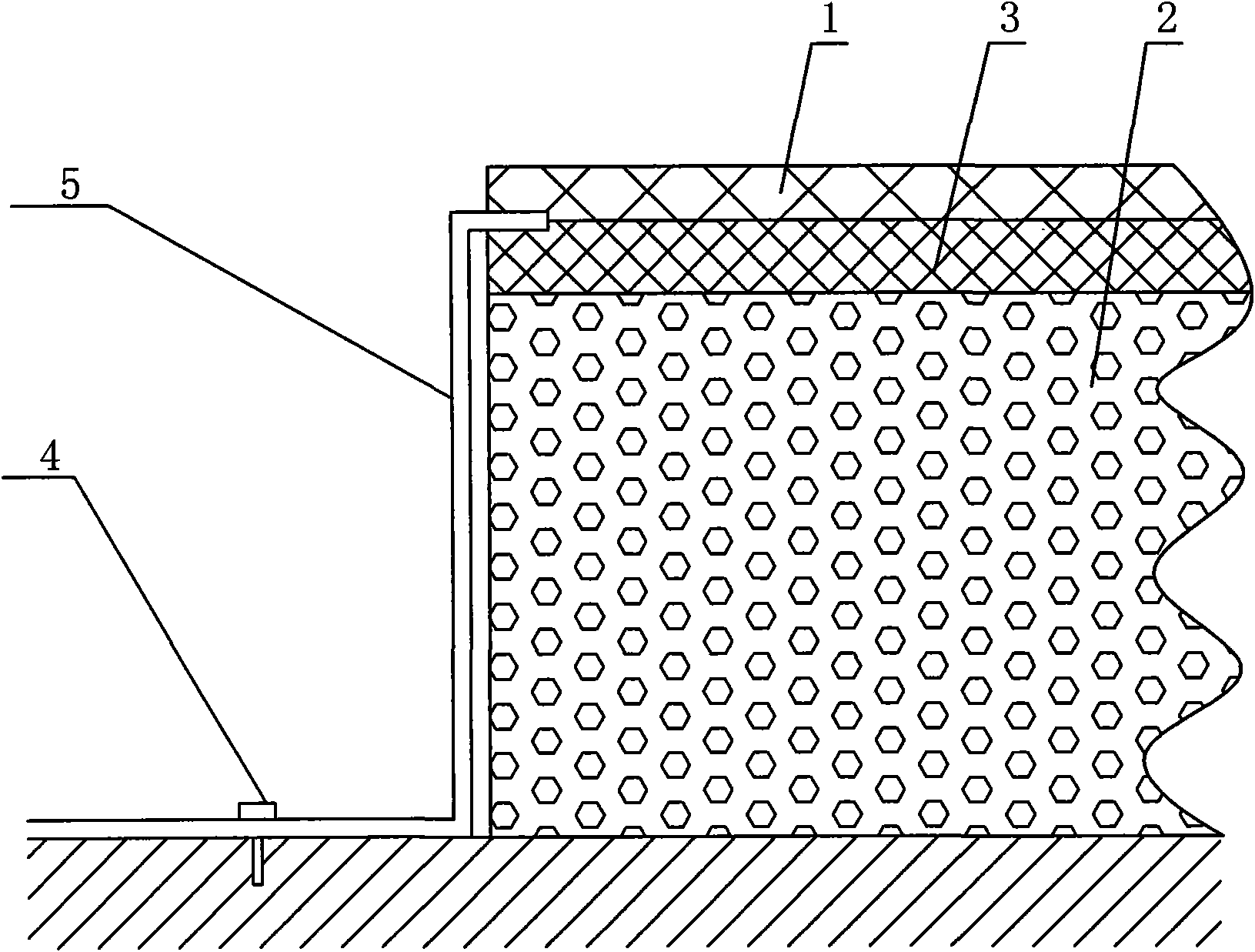

[0016] see figure 1 , The composite board of the present invention is composed of a surface layer 1, a thermal insulation layer 2 and a base layer 3. The surface layer is a stone layer 1, and the stone layer 1 is a natural stone layer or an artificial stone layer or a ceramic layer, and the stone layer in this embodiment is made of natural stone. Because natural stone has good weather resistance and weather resistance, and the surface color keeps for a long time, the composite board of the present invention can also have the characteristics of stone or natural stone. The thickness of the stone layer is 1-10mm, and the effect is better when the thickness of the stone layer is 2-5mm, which is 3.5mm in this embodiment. The interior of the thermal insulation layer 2 is covered with several small closed cells, which can make the heat transfer coefficient of the composite board small and play the role of thermal insulation. The thickness of the thermal insulation layer 2 is 20-80m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com