Large lattice structure with plate type grid substructure and cylindrical surface type crossed space truss system

A three-dimensional truss and grid structure technology, which is applied to building components, building structures, roofs, etc., can solve the problems of small structural thickness-span ratio, complex processing structure, and increased steel consumption, so as to reduce the workload of on-site installation , Save steel consumption and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

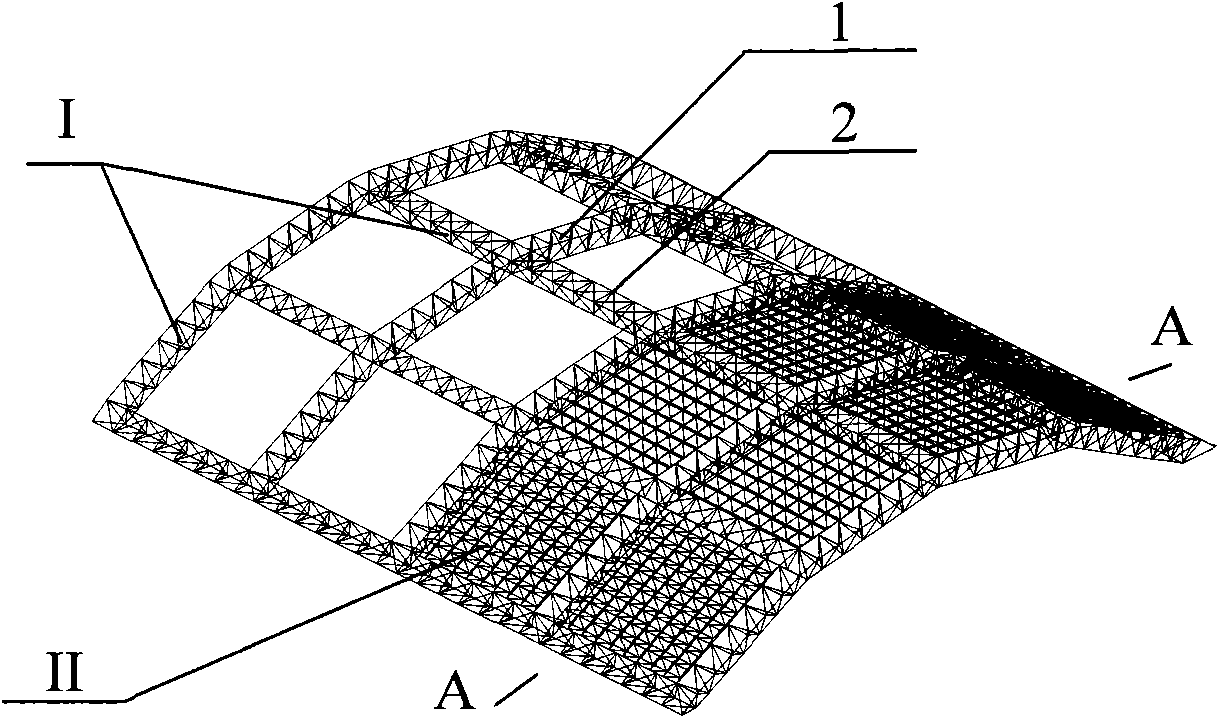

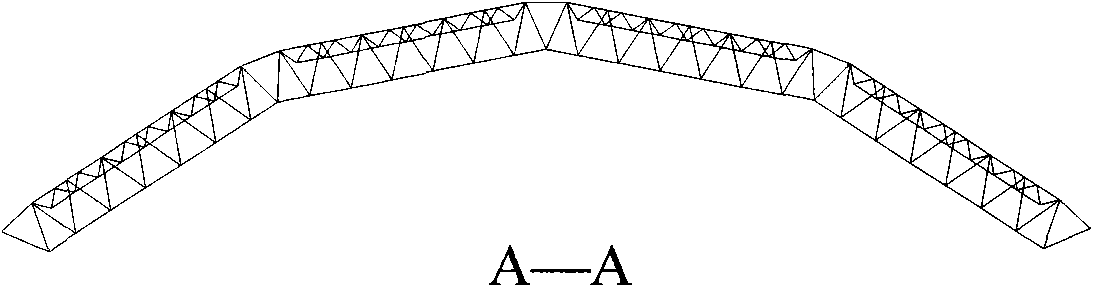

[0020] combine figure 1 with figure 2 :

[0021] The whole structure is composed of main structure I and substructure II arranged in the main structure. The main structure I is a large cylindrical grid structure formed by the intersection of horizontal three-dimensional truss 1 and vertical three-dimensional truss 2. The grid size is 10-30m. The substructure is an ordinary double-layer flat grid frame, which is embedded in the large grid to form a structural form of a large grid with a small grid. The load of the entire structure is relatively sparse. And the grand main structure bears.

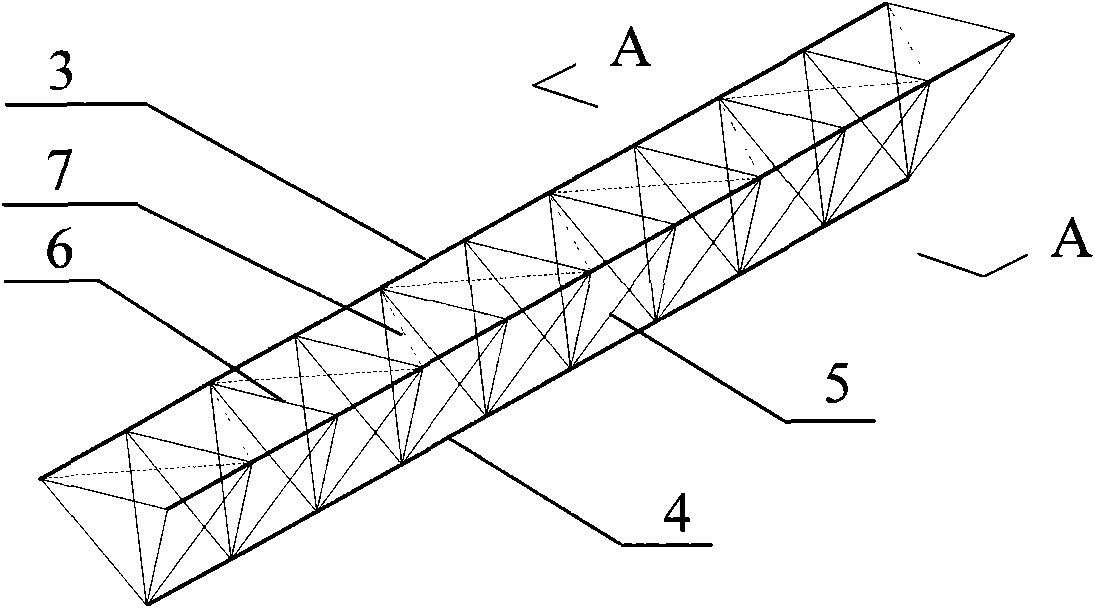

[0022] combine image 3 with Figure 4 : The horizontal three-dimensional truss 1 and the vertical three-dimensional truss 2 are all composed of two parallel upper chords 3 and one lower chord 4 to form a triangular section, a web 5 is arranged between the upper chord and the lower chord, and a web 5 is arranged between the two upper chords A plurality of crossbars 6, the distance betwe...

Embodiment 2

[0026] combine Figure 8 with Figure 9 : The difference between this embodiment and Embodiment 1 is that: the substructure II of this embodiment is embedded in the large grid of the main structure I in the manner of support at multiple points 11 around.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com