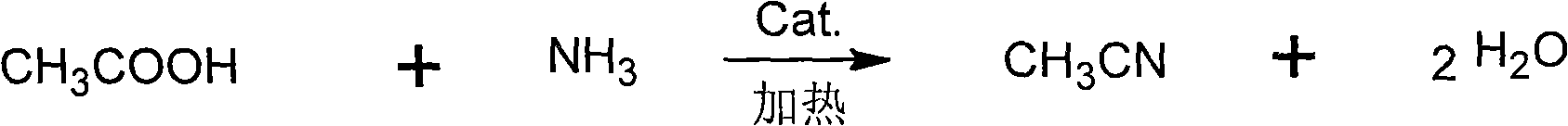

Method for synthesizing high purity acetonitrile by ammoniating acetic acid

A technology for chemical synthesis and ammonium acetate, applied in chemical instruments and methods, carboxylic acid nitrile purification/separation, organic chemistry, etc. Simple process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A method for synthesizing high-purity acetonitrile by ammoniation of acetic acid comprises the following steps successively:

[0034] (1) Reaction process

[0035] Acetic acid and liquid ammonia are vaporized separately, acetic acid is preheated to 100-250°C, liquid ammonia is preheated to 100-300°C, the two preheated gases enter the top of the reactor after mixing, and then enter the distributor to distribute evenly from the reaction The top of the reactor enters a fixed-bed reactor filled with an acetic acid ammoniation catalyst: the two raw materials undergo an ammoniation reaction at 350-500°C under the action of the catalyst, and the pressure at the top of the reactor is 5Kpa-25Kpa. The reaction molar ratio of the two raw materials is: acetic acid: liquid ammonia = 1: 0.1-1.0; reaction residence time: 3-7S.

[0036] Described catalyzer is the acetic acid ammoniation catalyst of carrier with Al2O3, and the composition of catalyzer is as follows:

[0037] A a B b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com