Process for preparing water-soluble ginkgo biloba extract used for injection

The technology of extract and ginkgo leaf is applied in the field of preparation technology of water-soluble ginkgo leaf extract, which can solve the problems of tannin residue, internal quality difference of ginkgo leaf extract, resin residue and the like, so as to reduce the internal quality difference and expand the Use range, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 7.2g of medicinal gelatin (bone glue) and add slowly to 4800ml of purified water heated to about 40°C in advance under stirring. Insulate and stir until the medicinal gelatin is completely dissolved into a uniform solution to obtain a 0.15% medicinal gelatin aqueous solution (g / v), which is set aside.

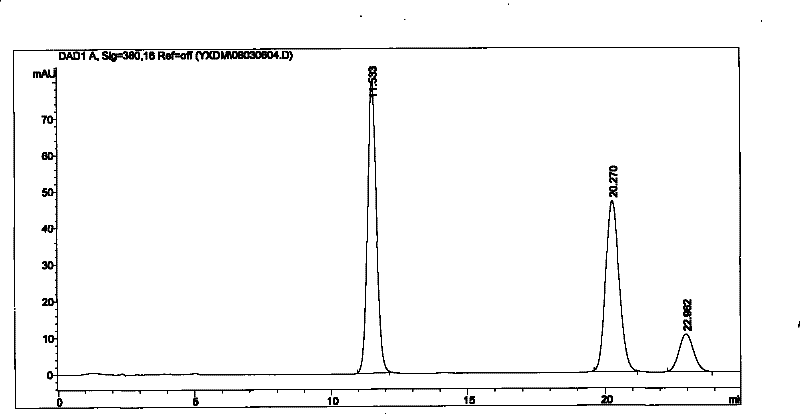

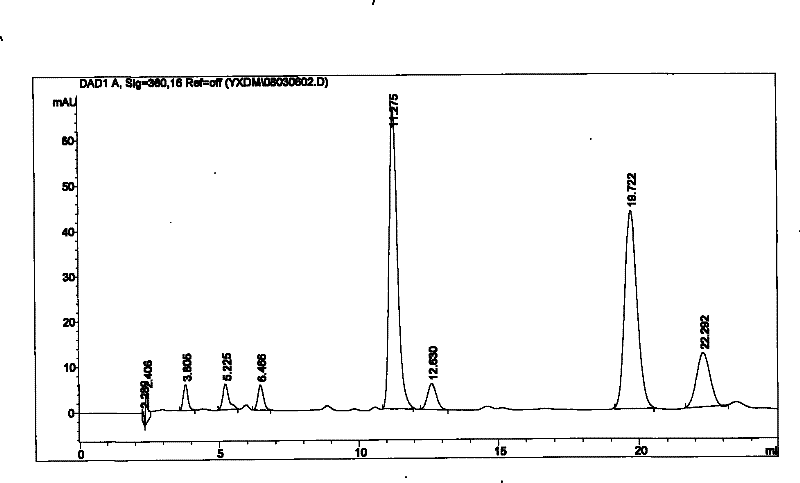

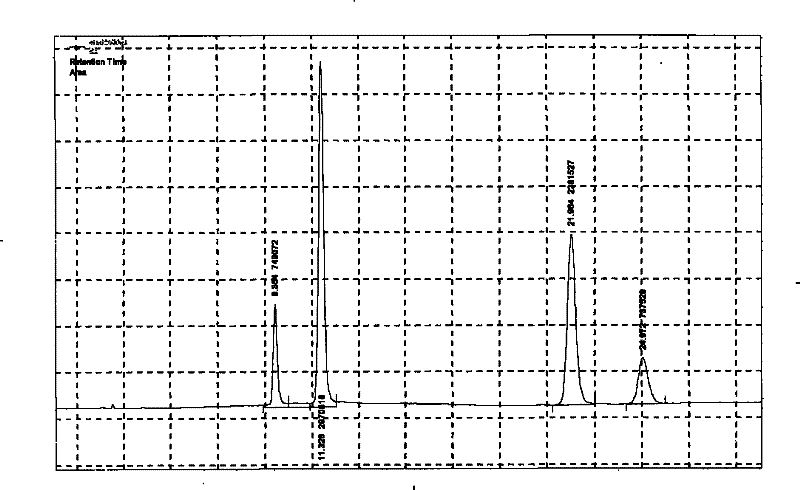

[0027] Weigh 80g Ginkgo biloba extract (Ginkgo biloba extract is produced by our company, production batch number 0691013, total flavonol glycoside content is 24.4%, terpene lactone content is 8.5%, moisture content is 3.4%, flavonoid aglycone peak area ratio is 0.9) Pour into the above-mentioned concentration of medicinal gelatin aqueous solution, heat up to 100° C., keep warm and stir for extraction for 30 minutes. After the extraction is completed, the extract is cooled to 10° C., allowed to stand and settle for 24 hours, the solution is filtered, the solids are discarded, and the filtrate is used for later use.

[0028] The above-mentioned filtrate is ultrafil...

Embodiment 2

[0033] Weigh 14.4g of medicinal gelatin (bone glue) and add slowly to 4800ml of purified water heated to about 40°C in advance under stirring. Insulate and stir until the medicinal gelatin is completely dissolved into a uniform solution to obtain a 0.30% medicinal gelatin aqueous solution (g / v), which is set aside.

[0034] Weigh 80g Ginkgo biloba extract (Ginkgo biloba extract is produced by our company, production batch number 0691013, total flavonol glycoside content is 24.4%, terpene lactone content is 8.5%, moisture content is 3.4%, flavonoid aglycone peak area ratio is 0.9) Pour into the above-mentioned concentration of medicinal gelatin aqueous solution, heat up to 100° C., keep warm and stir for extraction for 30 minutes. After the extraction is completed, the extract is cooled to 10° C., allowed to stand and settle for 24 hours, the solution is filtered, the solids are discarded, and the filtrate is used for later use.

[0035] The above-mentioned filtrate is ultrafi...

Embodiment 3

[0040] Weigh 4.8g of medicinal gelatin (bone glue) and add slowly to 4800ml of purified water heated to about 40°C in advance under stirring. Keeping warm and stirring until the medicinal gelatin is completely dissolved into a uniform solution to obtain a 0.10% medicinal gelatin aqueous solution (g / v), which is set aside.

[0041] Weigh 80g Ginkgo biloba extract (Ginkgo biloba extract is produced by our company, production batch number 0691013, total flavonol glycoside content is 24.4%, terpene lactone content is 8.5%, moisture content is 3.4%, flavonoid aglycone peak area ratio is 0.9) Pour into the above-mentioned concentration of medicinal gelatin aqueous solution, heat up to 100° C., keep warm and stir for extraction for 30 minutes. After the extraction is completed, the extract is cooled to 10° C., allowed to stand and settle for 24 hours, the solution is filtered, the solids are discarded, and the filtrate is used for later use.

[0042] The above-mentioned filtrate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com