Bag-cultivated edible fungi liquid spawn inoculation sealing device and operation process thereof

A technology of liquid strains and sealers, applied in horticulture, application, botany equipment and methods, etc., can solve the problems of low degree of automation, inconvenient sealing operation, large drainage resistance, etc., achieve high degree of automation and facilitate promotion Application, not easy to pollute the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

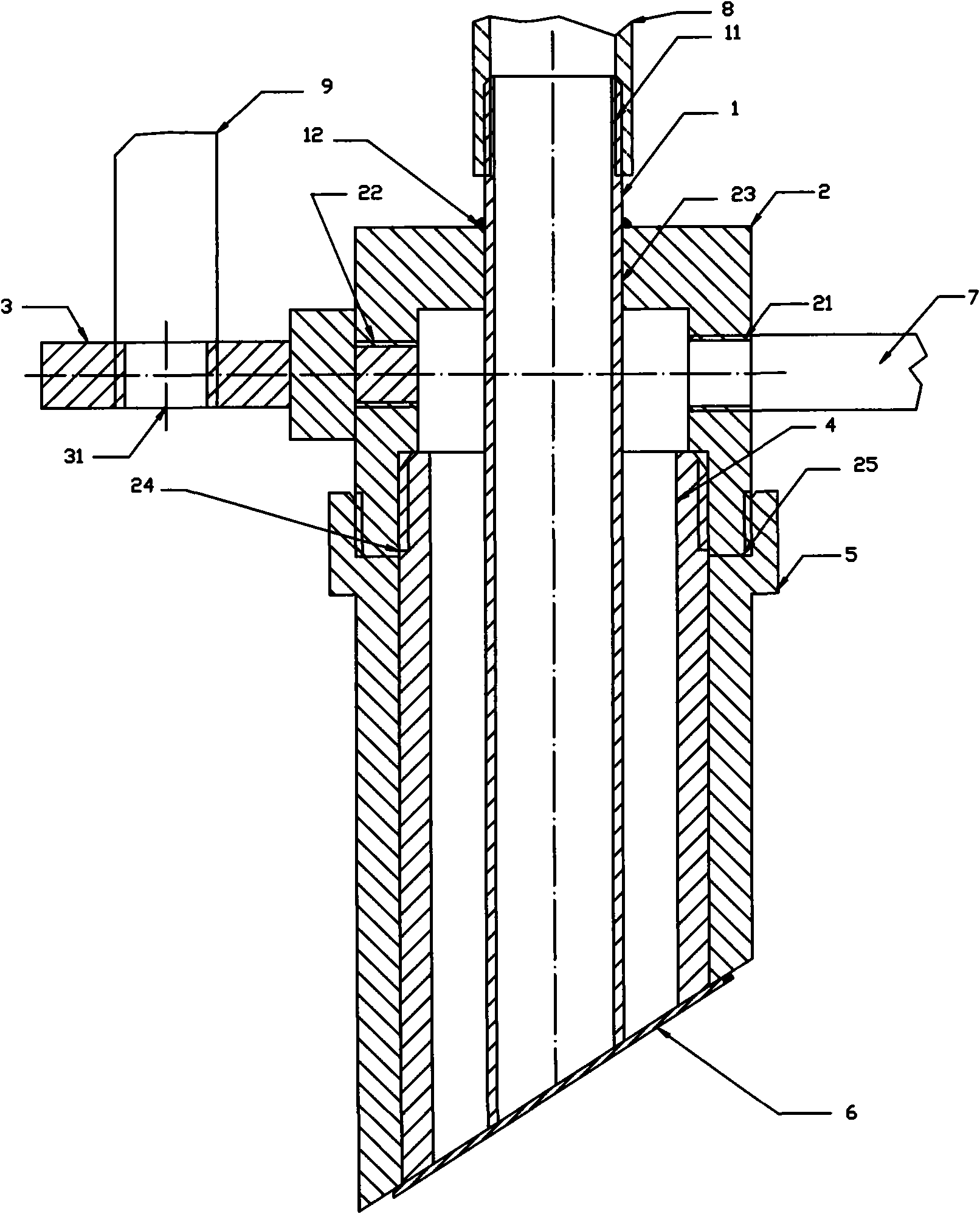

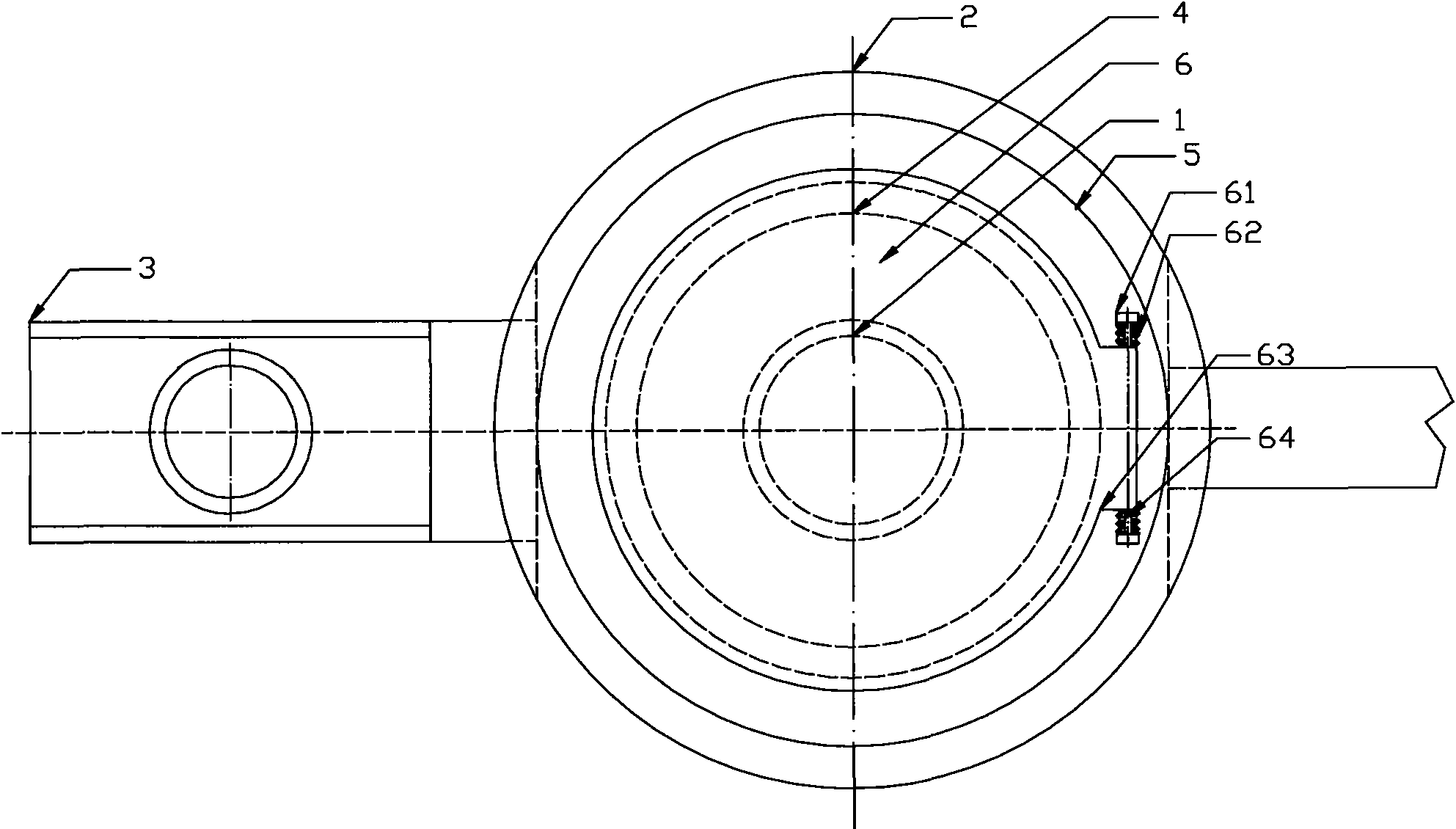

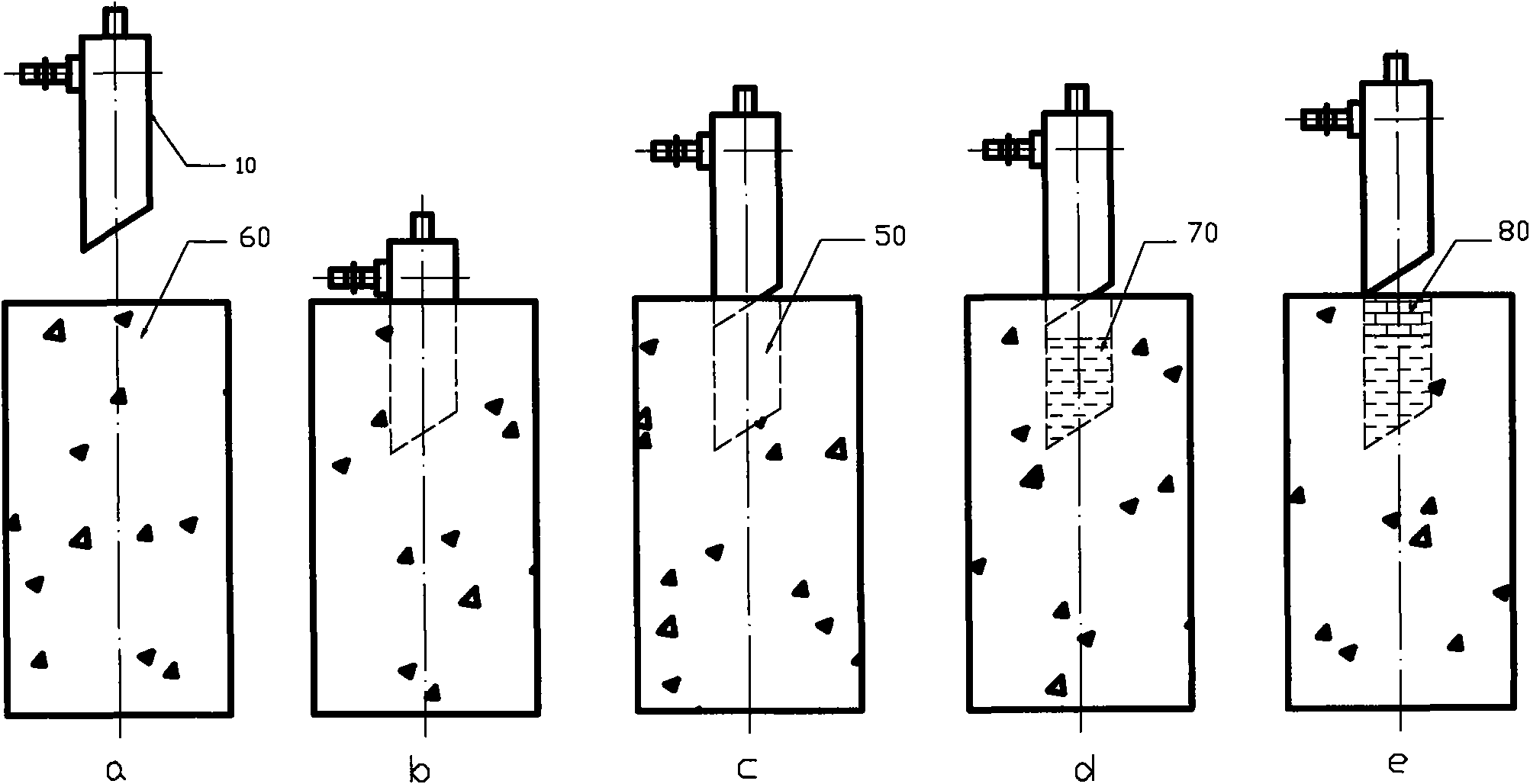

[0014] Such as figure 1 with 2 As shown, the liquid strain inoculation sealer for edible fungi in bags includes a cylindrical inoculation sealing head 5 with an inclined plane, an inoculation sealing seat 2, a sealing tube 1, an inoculation tube 4 and a support rod 3, a rotating cover plate 6, and a bacterial liquid delivery soft Pipe 7, sealing mud conveying hose 8 and cylinder and other actuator moving parts 9, etc., the structural installation relationship is: the sealing pipe 1 is embedded in the smallest hole 23 of the inoculation sealing seat 2, and is fixed by welding 12; The outside of the tube 1 is connected with the internal thread hole 24 of the inoculation sealing seat 2 through its external thread; the cylindrical inoculation sealing head 5 is set outside the inoculation tube 4, and is connected with the external thread hole 25 of the inoculation sealing seat 2 through its internal thread; the support rod 3 Connect with the internal thread 22 on one side of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com