Control method and controller of vertical crusher

A control method and technology of a grinding machine, applied in grain processing, etc., can solve problems such as surplus, operation stop, etc., and achieve the effect of suppressing abnormal vibration and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Preferred embodiments associated with a vertical grinder control method according to the present invention will be described below with reference to the accompanying drawings.

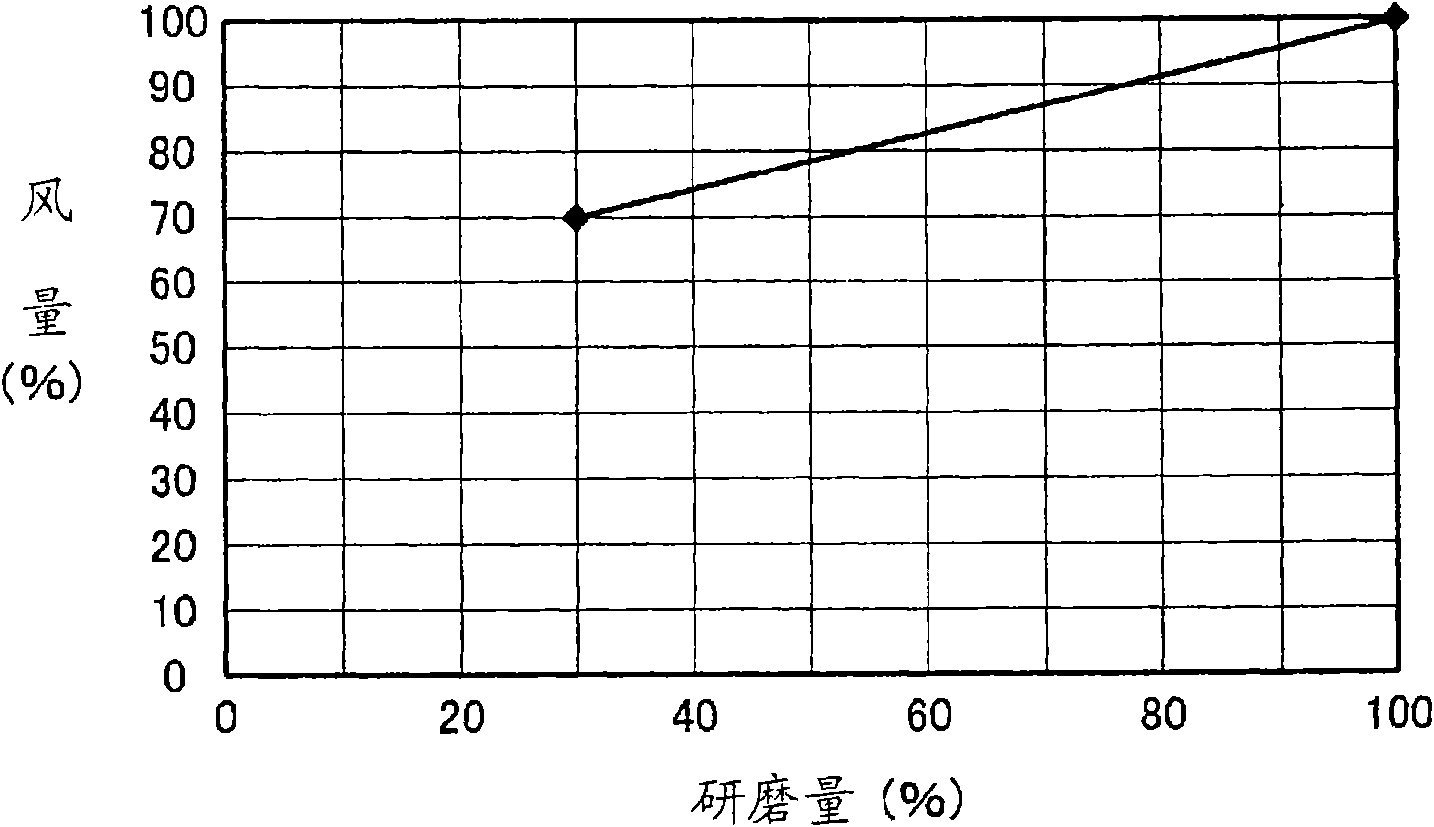

[0064] figure 1 is an illustration diagram for illustrating a schematic configuration of a vertical grinder that realizes the control method for the vertical grinder according to the first embodiment of the present invention. figure 2 It is an illustration diagram conceptually illustrating a grinding system using the same vertical grinding machine. image 3 It is a graph showing the relationship between the crushing amount and the air volume in the same vertical grinder. Figure 4 It is a graph showing the relationship between the table rotation speed of the rotary table and the load of the grinder in the same vertical grinder. Figure 5 It is a graph showing the relationship between the velocity of powdery particles inside the same vertical mill and the coefficient of dynamic friction. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com