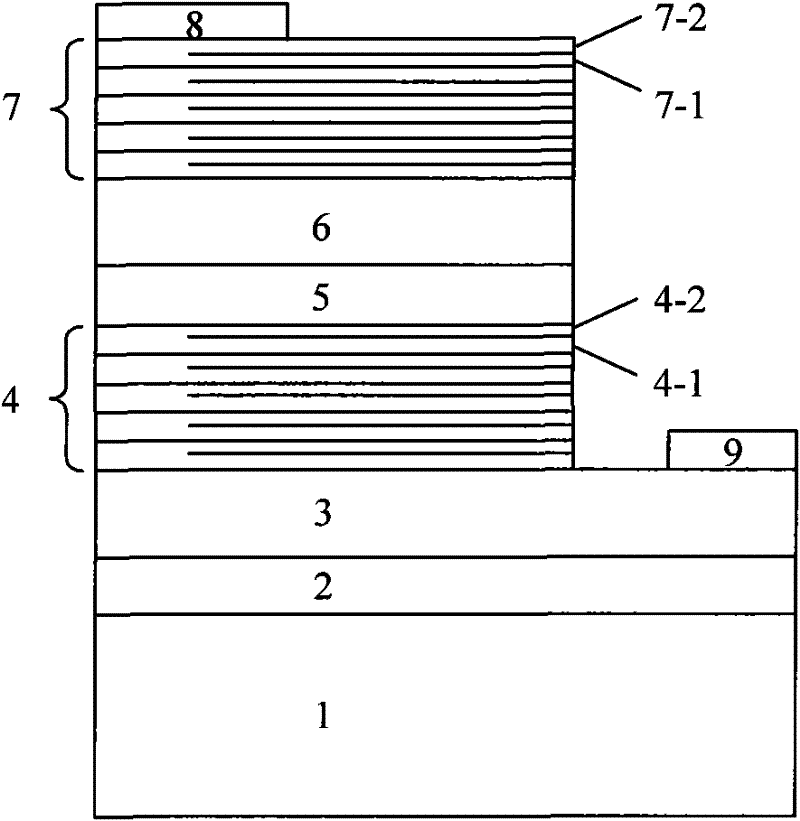

High-brightness light emitting diode with GaN-based multiquantum-well structure and preparation method thereof

A technology of light-emitting diodes and multiple quantum wells, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of small electron and hole radiation recombination probability and low luminous intensity, so as to suppress wavelength drift, enhance confinement, and improve The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

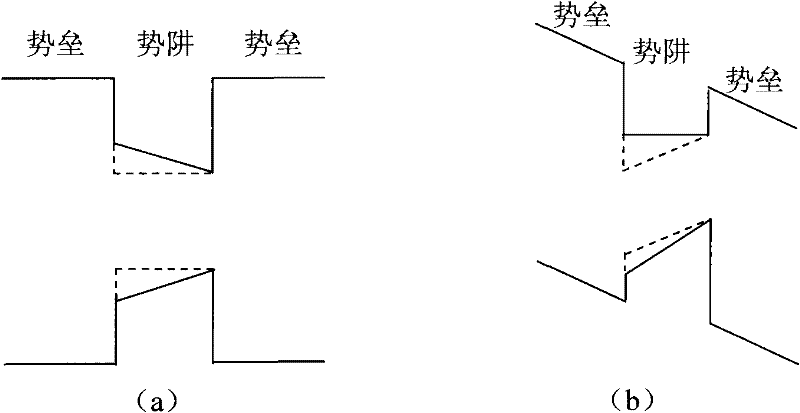

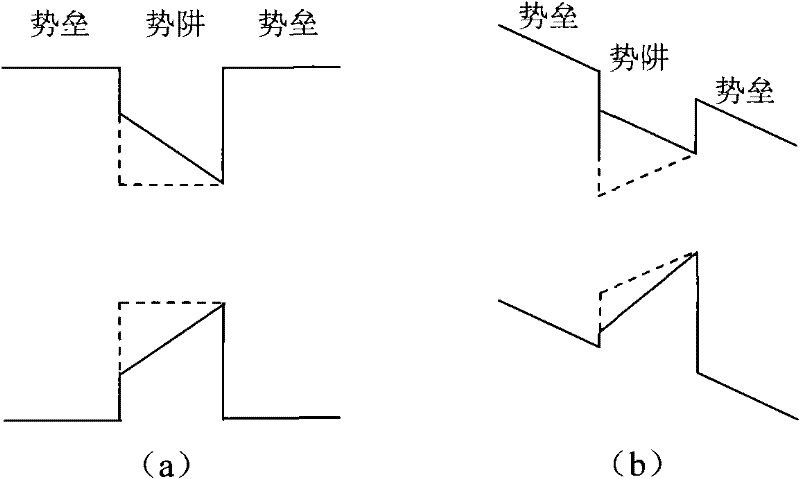

Method used

Image

Examples

Embodiment 1

[0040] 1. Put the no-clean (0001) surface sapphire substrate into the reaction chamber, 2 Under atmosphere, heat to 1050°C and bake for 10 minutes, and the pressure in the reaction chamber is 50 Torr.

[0041] 2. Grow a GaN buffer layer with a thickness of 10nm at 500°C, the growth pressure is 500Torr, the flow rate of carrier gas is 10L / min, the flow rate of TMGa is 20μmol / min, NH 3 The flow rate is 80mol / min.

[0042] 3. Grow an n-type silicon-doped GaN layer with a thickness of 2 μm at 950 ° C, the growth pressure is 100 Torr, the flow rate of carrier gas is 5 L / min, the flow rate of TMGa is 50 μmol / min, NH 3 The flow rate is 120mol / min, SiH 4 The flow rate is 0.2nmol / min.

[0043] 4. Then in N 2 Three periods of InGaN / GaN quantum wells were grown under the atmosphere, and the growth pressure was 50Torr. The well layer is InGaN, the thickness is 2nm, the flow rate of TMGa is 1μmol / min, the flow rate of TMIn is 10μmol / min, NH 3 The flow rate is 120mol / min, the growth t...

Embodiment 2

[0050] 1. Put the no-clean (0001) surface sapphire substrate into the reaction chamber, and 2 Heat to 1080° C. and bake for 12 minutes under atmosphere, and the pressure in the reaction chamber is 50 Torr.

[0051] 2. Grow a GaN buffer layer with a thickness of 15nm at 530°C, the growth pressure is 520Torr, the flow rate of carrier gas is 15L / min, the flow rate of TMGa is 30μmol / min, NH 3 The flow rate is 100mol / min.

[0052] 3. Grow an n-type silicon-doped GaN layer with a thickness of 2.3 μm at 980 ° C, the growth pressure is 150 Torr, the flow rate of carrier gas is 8 L / min, the flow rate of TMGa is 100 μmol / min, NH 3 The flow rate is 250mol / min, SiH 4 The flow rate is 0.5 nmol / min.

[0053] 4. Then in N 2 Four periods of InGaN / GaN quantum wells were grown under the atmosphere, and the growth pressure was 100Torr. The well layer is InGaN, the thickness is 3nm, the flow rate of TMGa is 2μmol / min, the flow rate of TMIn is 15μmol / min, NH 3 The flow rate is 250mol / min, th...

Embodiment 3

[0058] 1. Put the no-clean (0001) surface sapphire substrate into the reaction chamber, and 2 Under atmosphere, heat to 1100°C and bake for 15 minutes, and the reaction chamber pressure is 50 Torr.

[0059] 2. Grow a GaN buffer layer with a thickness of 20nm at 550°C, the growth pressure is 530Torr, the flow rate of carrier gas is 18L / min, the flow rate of TMGa is 40μmol / min, NH 3 The flow rate is 120mol / min.

[0060] 3. Grow an n-type silicon-doped GaN layer with a thickness of 2.5 μm at 1000 ° C, the growth pressure is 200 Torr, the flow rate of carrier gas is 10 L / min, the flow rate of TMGa is 120 μmol / min, NH 3 The flow rate is 280mol / min, SiH 4 The flow rate is 1 nmol / min.

[0061] 4. Then in N 2 InGaN / GaN quantum wells were grown for 5 periods under the atmosphere, and the growth pressure was 200Torr. The well layer is InGaN, the thickness is 4nm, the flow rate of TMGa is 3μmol / min, the flow rate of TMIn is 20μmol / min, NH 3 The flow rate is 350mol / min, the growth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com